Aerogel thermal-insulation damping coating

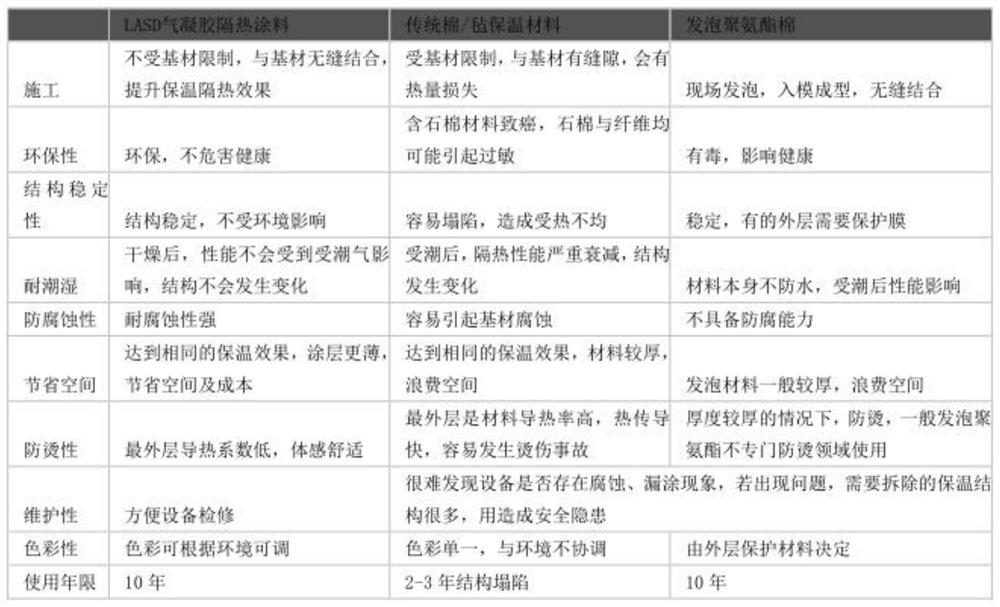

A damping coating and airgel technology, applied in the field of airgel, can solve problems such as change, performance impact, and non-waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The components of the airgel heat-insulating damping coating are composed by weight parts, 30 parts of acrylic dispersion, 1.5 parts of modified acrylic copolymer, 25 parts of acrylic emulsion, 0.5 parts of adhesion promoter, 2 parts of dispersant, nano heat insulation 1.5 parts of filler, 18 parts of macromolecular polysaccharide.

[0021] After testing, the thermal conductivity (W / m k) of the airgel thermal insulation damping coating is 0.032, the density (KG / L) is 0.54±0.02, the volume solid content (%) is 72%, and the long-term use temperature (°C)- 40~150.

Embodiment 2

[0023] The components of the airgel heat-insulating damping coating are composed by weight parts, 28 parts of acrylic acid dispersion, 1 part of modified acrylic acid copolymer, 20 parts of acrylic emulsion, 0.1 part of adhesion promoter, 1 part of dispersant, nano heat insulation 1 part of filler, 12 parts of macromolecular polysaccharide.

[0024] After testing, the airgel heat-insulating and damping coating has a temperature resistance range (°C) of -60 to 800, a moisture resistance (h) of 2000, an anti-aging (h) of 600, wear resistance, and is medium to strong.

Embodiment 3

[0026] The composition of the airgel heat-insulating damping coating by weight, 38 parts of acrylic dispersion, 2 parts of modified acrylic copolymer, 28 parts of acrylic emulsion, 0.9 parts of adhesion promoter, 3 parts of dispersant, nano heat insulation 2 parts of filler, 25 parts of macromolecular polysaccharide.

[0027] After testing, the adhesion (Mpa) of the airgel heat-insulating and damping coating is ≥ 1.5, the solar reflectance is 0.88, the hemispherical emissivity is 0.81, and the near-infrared reflectance is 0.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Long-term use temperature | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com