Polyantimonic acid/polyacrylonitrile composite ion exchanger and its preparation method and use

A technology of polyacrylonitrile and composite ions, applied in chemical instruments and methods, other chemical processes, nuclear engineering, etc., can solve problems such as complicated operation, difficult molding, and the extraction agent is not resistant to radiation, and achieves a simple and easy-to-operate preparation method , good chemical stability, excellent ball forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

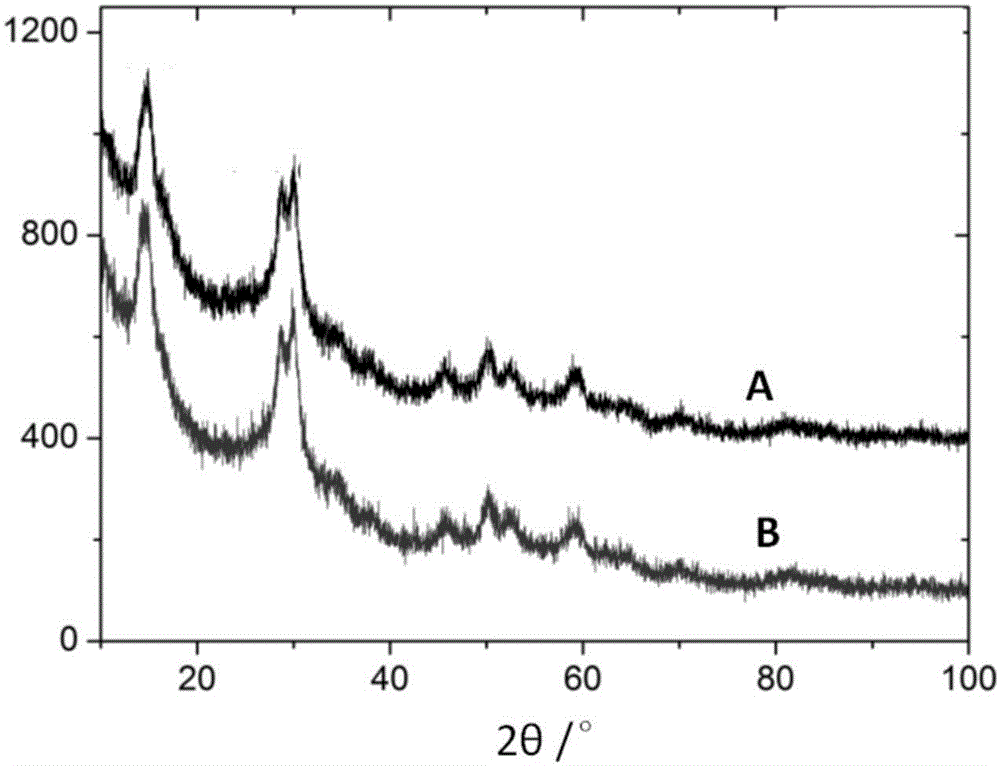

[0040] The preparation method of polyantimonic acid particles in the following examples is as follows:

[0041] ①Add 50g of antimony trichloride solid to 40mL of concentrated nitric acid solution, age for 6 days, and form a white sol; ②Add ammonia water to adjust the pH to 9, add 100mL of deionized water to hydrolyze to form a white precipitate, centrifuge, and dry at 70°C Dry for 24 hours; ③ use 0.1mol / L HNO 3 After rinsing for 3 times, rinse with deionized water again, and then centrifuge and wash with deionized water for 4 times until the pH of the supernatant of the centrifugal precipitation is 5; ④Dry the precipitate at 80°C, grind the dried precipitate Grind and sieve into 60-150 mesh polyantimony acid particles.

Embodiment 1

[0043] (1) Take the above 10g of polyantimonic acid particles and add them to a 150mL three-neck round bottom flask, then add 40mL of dimethyl sulfoxide and 0.3g of Tween-80, and stir at 60°C for 1 hour to obtain a mixed solution;

[0044] (2) Stir the mixed solution and 4g of polyacrylonitrile at 50°C for 5h and mix evenly to obtain a uniform white emulsion;

[0045] (3) Bring the emulsion into the nozzle with a peristaltic pump at a flow rate of 10mL / m, drop it into deionized water with a rotation speed of 250r / min to prepare spherical particles, then wash with deionized water three times, and dry at 50°C for 18h. A spherical polyantimonic acid / polyacrylonitrile composite ion exchanger was obtained.

Embodiment 2

[0047] (1) Take the above 10g of polyantimonic acid particles and add them to a 150mL three-neck round bottom flask, then add 40mL of dimethyl sulfoxide and 0.3g of Tween-80, and stir at 50°C for 2h to obtain a mixture;

[0048] (2) Stir the mixed solution and 4 g of polyacrylonitrile at 50° C. for 5 h and mix evenly to obtain a uniform white emulsion;

[0049] (3) Bring the emulsion into the nozzle with a peristaltic pump at a flow rate of 12mL / m, drop it into deionized water with a rotation speed of 300r / min to prepare spherical particles, then wash with deionized water 4 times, and dry at 60°C for 24h. A spherical polyantimonic acid / polyacrylonitrile composite ion exchanger was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com