Preparation method of high-performance polyphenylene oxide/graphene nano composite material

A nanocomposite material and composite material technology, applied in the field of polyphenylene ether/graphene nanocomposite material preparation, can solve the problems of limited research and application, strong van der Waals force, easy agglomeration, etc., to achieve enhanced interfacial bonding and enhanced dispersion , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

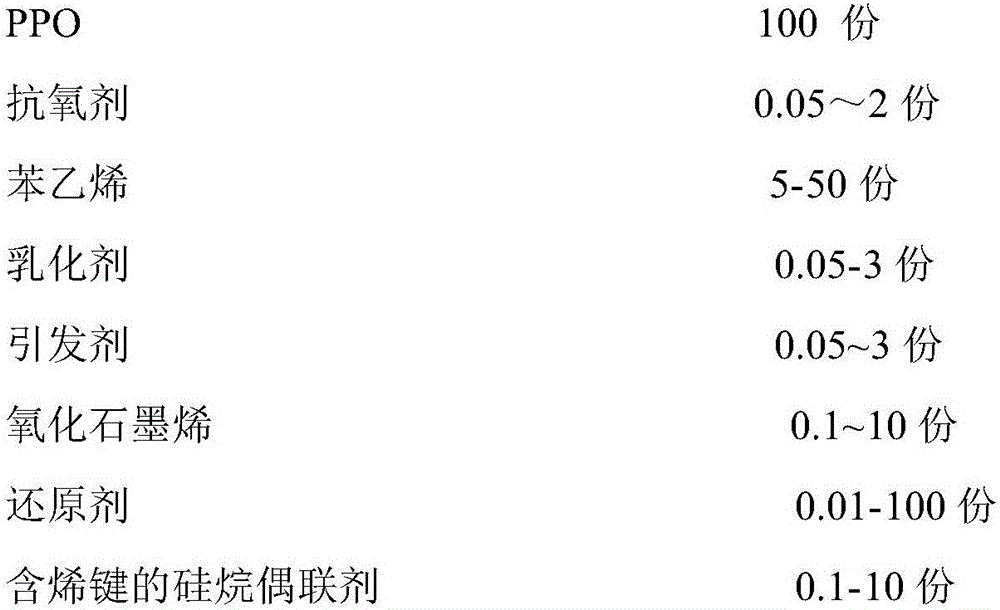

Method used

Image

Examples

Embodiment 1

[0021] Disperse 10g of graphene oxide in 1000g of deionized water, add 5g of vinyltriethoxysilane and stir evenly at room temperature, use ultrasonic dispersion for 30min, the ultrasonic power is 2000w, the frequency is 20000HZ, and the ultrasonic temperature is 80°C; then at 70°C Add 2g of sodium lauryl sulfate, stir to dissolve, then add 100g of styrene, pass nitrogen to remove oxygen for 30 minutes, and make it fully emulsified; add 1g of ammonium cerium nitrate, stir well, and react for 4h; continue to add 50g of hydrazine hydrate, at 80 Reduction reaction in oil bath at ℃ for 8h, filter the product, wash with distilled water, dry at 90℃ for 8h to constant weight, and pulverize to obtain polystyrene / graphene nanocomposite powder;

[0022] Add PPO 1Kg and tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester 5g, polystyrene / graphene nanocomposite powder 100g and add in high-speed mixer and mix, then Use a twin-screw extruder to melt and knead...

Embodiment 2

[0024] Disperse 50g of graphene oxide in 7000g of deionized water, add 100g of vinyl-tris(β-methoxyethoxy)silane and stir evenly at room temperature, use ultrasonic dispersion for 100min, ultrasonic power is 3000w, frequency is 40000HZ, ultrasonic temperature at 60°C; then add 4g of sodium dodecylsulfonate at 80°C, stir to dissolve, then add 300g of styrene, pass nitrogen to remove oxygen for 30 minutes, and make it fully emulsified; add 1.2g of potassium persulfate, stir evenly, and react 6h; continue to add 500g of sodium borohydride, reduce in an oil bath at 100°C for 6h, filter the product, wash with distilled water, dry at 90°C for 8h to constant weight, and pulverize to obtain polystyrene / graphene nanocomposite powder;

[0025] PPO 1Kg and β-(4-hydroxyl-3,5-di-tert-butylphenyl) octadecyl propionate 10g, polystyrene / graphene nanocomposite powder 350g are added in the high-speed mixer and mixed, and then The twin-screw extruder melts and kneads, extrudes and granulates, th...

Embodiment 3

[0027] Disperse 30g of graphene oxide in 5000g of deionized water, add 30g of γ-propylmethacrylatetrimethoxysilane and stir evenly at room temperature, and disperse by ultrasonic wave for 200min, with ultrasonic power of 800w, frequency of 60000HZ, and ultrasonic temperature of 50°C; Then add 3g of sodium dodecylbenzenesulfonate at 85°C, stir to dissolve, then add 200g of styrene, pass nitrogen to remove oxygen for 30 minutes, and make it fully emulsified; add 0.8g of ammonium persulfate, stir evenly, and react for 8h; then Add 200g of vitamin C, perform reduction reaction in an oil bath at 60°C for 4h, filter the product, wash with distilled water, dry at 90°C for 8h to constant weight, and pulverize to obtain polystyrene / graphene nanocomposite powder;

[0028]Add 1Kg of PPO, 3g of N,N'-bis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine, and 230g of polystyrene / graphene nanocomposite powder Mix in a high-speed mixer, then melt and knead with a twin-screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com