Corn field special-purpose degradable environmental protection mulch film, and preparation method thereof

A technology of corn field and plastic film, which is applied in botany equipment and methods, applications, plant protection, etc., can solve the problems of difficult control of degradation time, increase of corn planting cost, and difficult farmers' wide acceptance, so as to improve mechanical properties and degradation performance , Particle size reduction, apparent viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

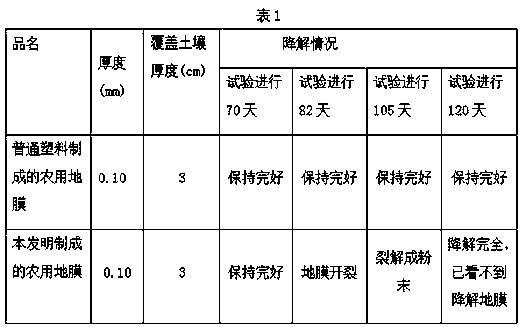

Image

Examples

Embodiment 1

[0025] A special degradable environmental protection mulch film for corn fields, comprising the following raw materials in weight fractions:

[0026] 90 parts of linear low-density polyethylene; 10 parts of low-density polyethylene; 40 parts of modified tapioca starch; 7 parts of modified nano-calcium carbonate; 5 parts of bagasse powder; 2 parts of polyvinyl alcohol; 0.08 parts of photosensitizer iron stearate ; 0.05 part of phosphite type antioxidant; 0.3 part of thermal degradation accelerator cobalt stearate powder; 1 part of compatibilizer acrylic acid modified polylactic acid oligomer; 2 parts of plasticizer ethylene glycol; wherein bagasse powder The fineness is above 1000 mesh;

[0027] The preparation method of the modified tapioca starch is as follows: (1) drying the tapioca starch at 100° C. for 3 hours to obtain dried tapioca starch, then putting the tapioca starch into an ultrasonic oscillator and vibrating ultrasonically at 80 MHz for 3 hours, Obtain micronized ...

Embodiment 2

[0033] A special degradable environmental protection mulch film for corn fields, comprising the following raw materials in weight fractions:

[0034] 95 parts of linear low-density polyethylene; 13 parts of low-density polyethylene; 45 parts of modified tapioca starch; 10 parts of modified nano-calcium carbonate; 8 parts of bagasse powder; 2.5 parts of polyvinyl alcohol; 0.12 parts of photosensitizer iron stearate 0.08 part of phosphite type antioxidant; 0.4 part of thermal degradation accelerator iron laurate; 2 parts of compatibilizer monomer fatty acid glyceride; 4 parts of plasticizer propylene glycol; The fineness of described bagasse powder is at 1000 above the order;

[0035] The preparation method of the modified tapioca starch is as follows: (1) drying the tapioca starch at 110° C. for 2.5 hours to obtain dried tapioca starch, then putting the tapioca starch into an ultrasonic oscillator and vibrating ultrasonically at 85 MHz for 2.5 hours, Obtain micronized tapioca ...

Embodiment 3

[0040] A special degradable environmental protection mulch film for corn fields, comprising the following raw materials in weight fractions:

[0041] 100 parts of linear low-density polyethylene; 15 parts of low-density polyethylene; 50 parts of modified tapioca starch; 12 parts of modified nano-calcium carbonate; 10 parts of bagasse powder; 3 parts of polyvinyl alcohol; 0.2 parts of photosensitizer iron stearate 0.1 part of phosphite type antioxidant; 0.5 part of thermal degradation accelerator cobalt stearate powder; 3 parts of compatibilizer acrylic acid modified polylactic acid oligomer and 5 parts of plasticizer glycerol; described sugarcane The fineness of slag powder is above 1000 mesh;

[0042] The preparation method of the modified tapioca starch is as follows: (1) drying the tapioca starch at 120° C. for 2 hours to obtain dried tapioca starch, and then putting the tapioca starch into an ultrasonic oscillator and ultrasonically vibrating at 90 MHz for 2 hours, Obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com