Preparing method for low-heat-conductivity SiCN-Y2SiO5 environment blocking composite coating

A technology of composite coating and low thermal conductivity, which is applied in the field of preparation of polymer precursor ceramic outer coating, can solve the problem of difficulty in controlling the thickness of easy-to-crack coating, pore structure, uniform distribution and pore size, and the difficulty of coating composition Control and other issues to achieve good thermal shock resistance and water vapor oxidation resistance, excellent oxidation resistance and water vapor corrosion resistance, and prevent the formation of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

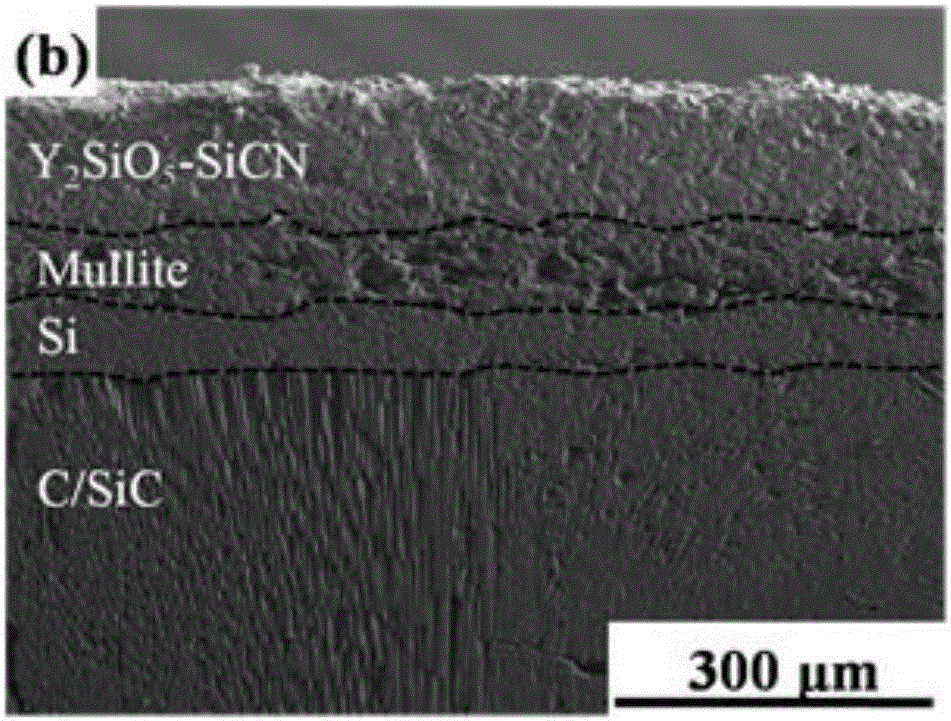

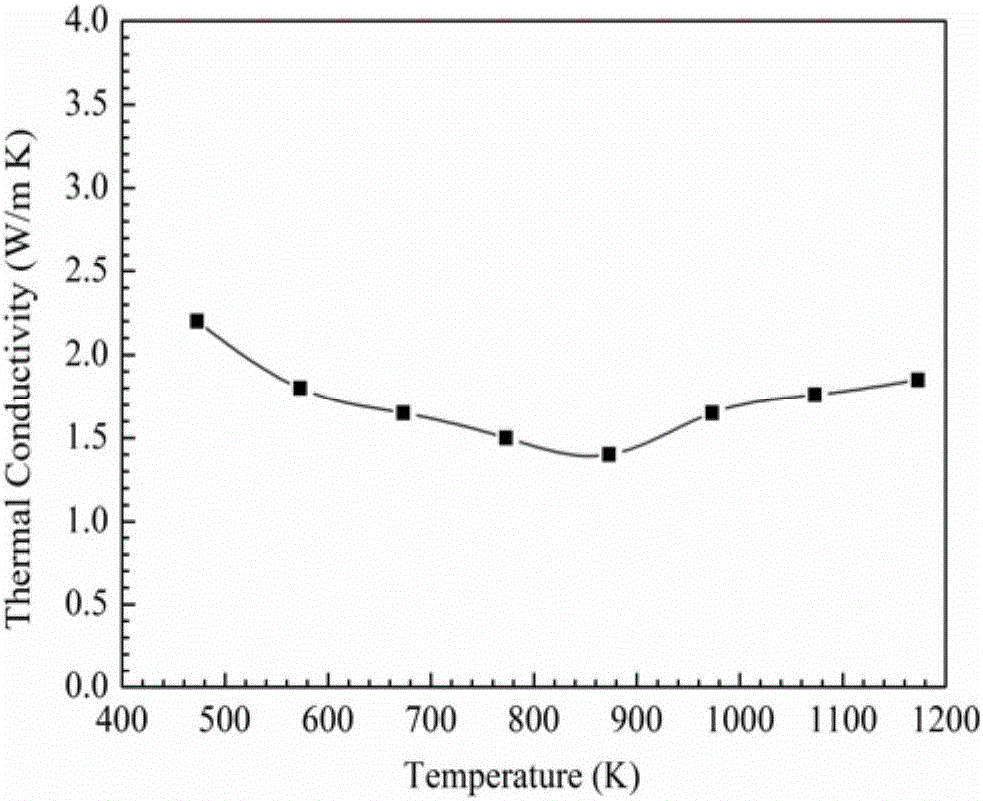

[0031] A low thermal conductivity SiCN-Y 2 SiO 5 The preparation method of the environmental barrier composite coating adopts the following steps:

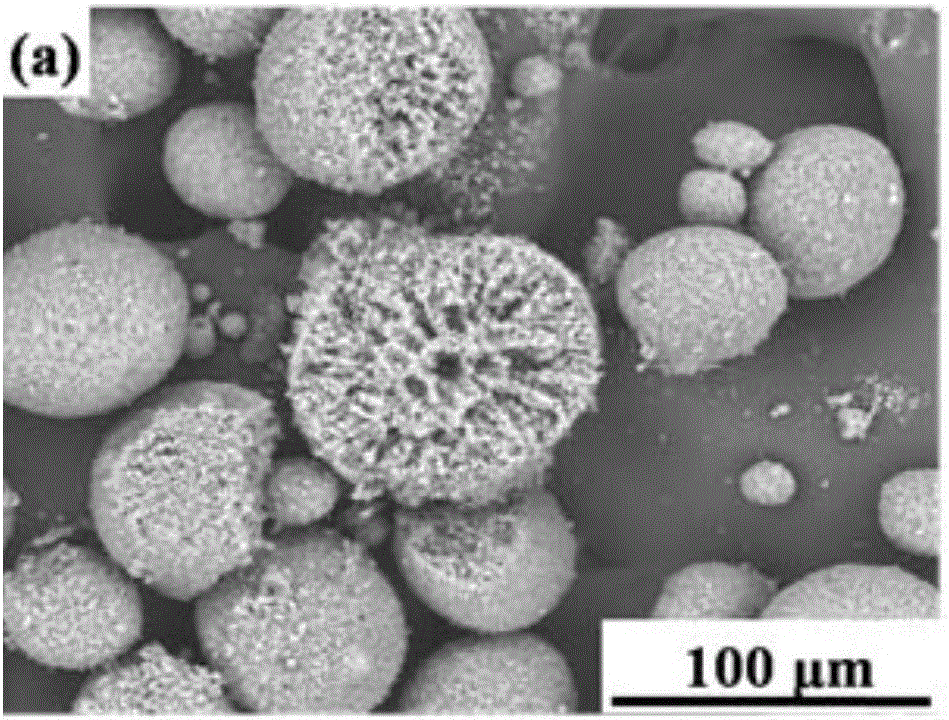

[0032] (1) Take the solid phase sintering method (Ziqi Sun, Meishuan Li, Yanchun Zhou. Thermal properties of single-phase Y 2 SiO 5 [J].Journal of the European Ceramic Society.29(2009)551-557.) Synthesized Y 2 SiO 5 Powder, using absolute ethanol as the ball milling medium, using a planetary ball mill for 48 hours, and after drying, use an agate mortar to grind for use (0.5-1 μm); Silazane (prepared by Northwestern Polytechnical University, PSN) was pyrolyzed in a high-temperature tube furnace at 1200 °C for 2 h under the protection of argon atmosphere, and the heating rate and cooling rate were controlled at 5 °C / min to obtain SiCN ceramic powder (60 nm );

[0033] (2) The above ceramic aggregate powder Y 2 SiO 5 and SiCN according to the mass ratio (6:4) uniform grinding and mixing, respectively dispersed in the isopropa...

Embodiment 2

[0040] A low thermal conductivity SiCN-Y 2 SiO 5 The preparation method of the environmental barrier composite coating adopts the following steps:

[0041] (1) Take the solid phase sintering method (Ziqi Sun, Meishuan Li, Yanchun Zhou. Thermal properties of single-phase Y 2 SiO 5 [J].Journal of the European Ceramic Society.29(2009)551-557.) Synthesized Y 2 SiO 5 Powder, using absolute ethanol as the ball milling medium, using a planetary ball mill for 48 hours, and after drying, use an agate mortar to grind for use (0.5-1 μm); Silazane (prepared by Northwestern Polytechnical University, PSN) was pyrolyzed in a high-temperature tube furnace at 1100 °C for 3 h under the protection of argon atmosphere, and the heating rate and cooling rate were controlled at 4 °C / min to obtain SiCN ceramic powder (80 nm );

[0042] (2) The above ceramic aggregate powder Y 2 SiO 5and SiCN according to the mass ratio of (5:5) uniform grinding and mixing, respectively dispersed in isopropano...

Embodiment 3

[0048] A low thermal conductivity SiCN-Y 2 SiO 5 The preparation method of the environmental barrier composite coating adopts the following steps:

[0049] (1) Take the solid phase sintering method (Ziqi Sun, Meishuan Li, Yanchun Zhou. Thermal properties of single-phase Y 2 SiO 5 [J].Journal of the European Ceramic Society.29(2009)551-557.) Synthesized Y 2 SiO 5 Powder, using absolute ethanol as the ball milling medium, using a planetary ball mill for 48 hours, and after drying, use an agate mortar to grind for use (0.5-1 μm); Silazane (prepared by Northwestern Polytechnical University, PSN) was pyrolyzed in a high-temperature tube furnace at 1000 °C for 4 h under the protection of argon atmosphere, and the heating rate and cooling rate were controlled at 2 °C / min to obtain SiCN ceramic powder (120 nm );

[0050] (2) The above ceramic aggregate powder Y 2 SiO 5 and SiCN according to the mass ratio (7: 3) uniform grinding and mixing, respectively dispersed in isopropano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com