Infrared Absorbing High Aluminosilicate Glass-Ceramics Doped with Samarium and Ytterbium

A high-aluminosilicate, infrared absorption technology, applied in the field of inorganic non-metallic photoelectric information and functional materials, can solve the problems of reducing the cooling efficiency of the cooling liquid on the gain medium, complex manufacturing process, and reducing laser efficiency, etc., to achieve extended use The effect of life and working frequency, improving laser efficiency and increasing crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

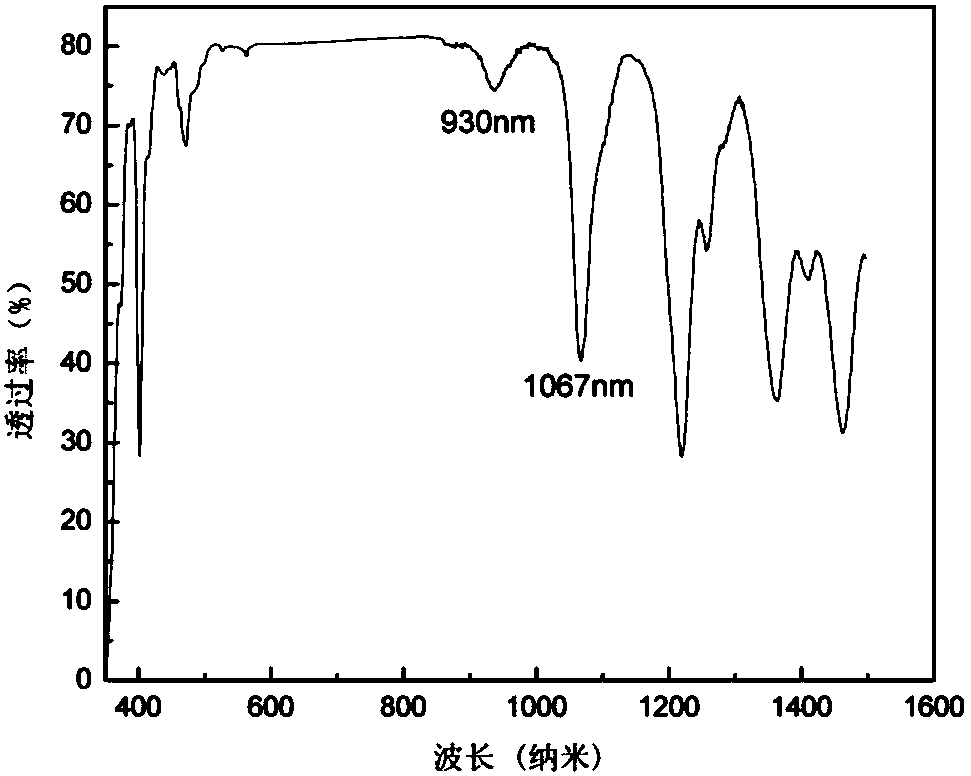

[0023] A glass-ceramic filter material with ultraviolet cut-off for xenon lamp spectrum, the glass has tunable cut-off for xenon lamp spectrum in the range of 400-600nm.

[0024] 1. Preparation process:

[0025] The first step: the formula is (by mole percentage):

[0026] Composition mol%

[0027] SiO 2 50

[0028] Al 2 o 3 35

[0029] MgO 10

[0030] ZnO2

[0031] Li 2 O 1.7

[0032] ZrO 2 0.5

[0033] TiO 2 0.2

[0034] SM 2 o 3 0.5

[0035] Yb 2 o 3 0.1

[0036] Step two:

[0037] According to the ingredients of the formula given in the first step, the raw materials are fully mixed evenly;

[0038] Step 3: At 1500°C, add the mixture to the quartz crucible / corundum crucible, platinum

[0039] In a crucible, melt for 4 hours by melting method;

[0040] Step 4: Clarify the glass liquid at 1550°C for 6 hours;

[0041] The sixth step: carry out mechanical stirring for 9 hours;

[0042] Step 7: Pour the prepared glass liquid into graphite or cast i...

Embodiment 2

[0047] Test and application are the same as Example 1, but the preparation process is different, as follows:

[0048] Preparation Process:

[0049] The first step: the formula is (by mole percentage):

[0050] Composition mol%

[0051]

[0052] Step two:

[0053] According to the ingredients of the formula given in the first step, the raw materials are fully mixed evenly;

[0054] Step 3: At 1550°C, add the mixture to the quartz crucible / corundum crucible and platinum crucible in 4 to 6 times, and melt it for 4 hours by melting method;

[0055] Step 4: Clarify the molten glass at 1580°C for 6 hours;

[0056] The sixth step: carry out mechanical stirring for 9 hours;

[0057] Step 7: Pour the prepared glass liquid into graphite or cast iron molds to shape;

[0058] Step 8: After holding the heat for 4 hours at 800°C in the muffle furnace, perform conventional annealing treatment;

[0059] Step 9: Cut and finely grind the obtained glass, and after polishing, carry out ...

Embodiment 3

[0062] Other implementation methods are all the same as Examples 1 and 2, except that the formula in the preparation process is different. Some components are listed below.

[0063] Example

3

4

5

6

7

8

9

10

11

12

13

14

SiO 2

40

50

48

45

40

40

40

40

45

50

45

50

Al 2 o 3

25

35

20

30

35

35

35

35

30

25

25

25

Li 2 o

5

0

2

1.5

0

0

0

0

2

5

0

2

MgO

15

5

10

10

15

15

10

5

0

5

10

10

ZnO

0

5

10

5

4.5

4.5

5

10

15

5

4

3

TiO 2

10

1.5

3

4.5

0

0

4.5

7

3.5

4

10

3

ZrO 2

2

0.5

2

0.5

0.5

0.5

0.5

0.5

0.5

1

2

0.5

CeO 2

0

0.2

2

0

3

3

2

1.5

3

2

3

5

SM 2 o 3

3

2.8

2.5

3

1.5

2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com