Power gain type solar backboard material

A solar back sheet and power gain technology, applied in electronic equipment, home appliances, applications, etc., can solve the problems of reducing power generation costs, narrow space for raw and auxiliary materials to fall, and achieve long-term stability guarantee, dimensional stability and weather resistance. Good and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

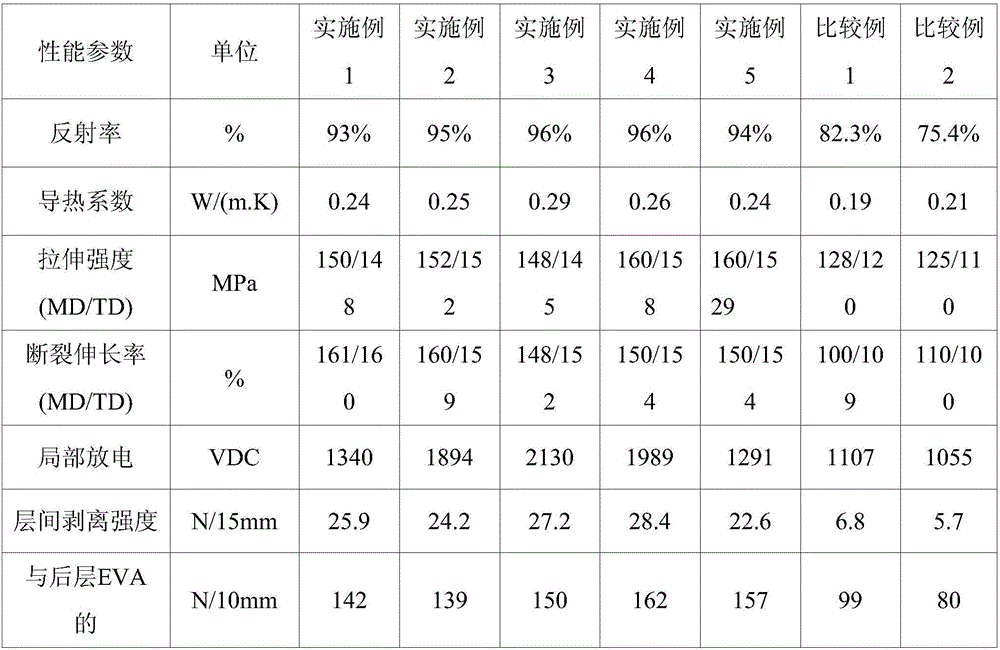

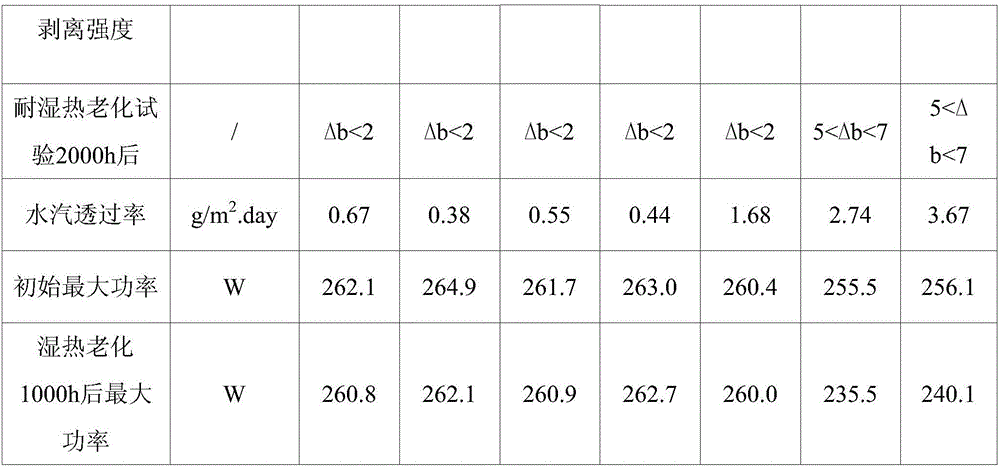

Embodiment 1

[0058] The backplane manufacturing process is as follows:

[0059] First, the substrate layer ingredients are polyethylene terephthalate (U.S. DuPont) 60wt%, titanium dioxide R902 (U.S. DuPont) 35wt%, hydrolysis stabilizer phenyl glycidyl ether (Hongyu Chemical Co., Ltd.) 4wt %, anti-thermal oxygen aging agent 2'-methylene bis-(4-methyl-6-tert-butylphenol) (Germany BASF) 1wt%. After mixing evenly, melt processing at 250-300°C.

[0060]The ingredients of the gain layer are 50wt% of ethylene-propylene copolymer (U.S. Dow Chemical Company), 4.9wt% of 3-(methacryloyl chloride) propyl trimethoxysilane (Sartomer Company) and methacrylic acid hydroxy Ethyl ester (Sartomer Company) 4wt%, flaky wet-process mica powder (Fengshuo Chemical Co., Ltd.) 5wt%, ceramic microspheres (King Kong New Materials Co., Ltd.) 10wt%, titanium dioxide R706 (U.S. DuPont) 25wt%, UV Absorber 2-[4-[2-Hydroxy-3-dodecyloxypropyl]oxy]-2-hydroxyphenyl]-4,6-bis(2,4-dimethylphenyl) -1,3,5-triazine (Germany BASF...

Embodiment 2

[0064] The backplane manufacturing process is as follows:

[0065] First, the base layer ingredients are polybutylene terephthalate (DuPont, USA) 95wt%, UV absorber 2-(4,6-bis(2,4-dimethylphenyl)-1,3, 5-triazin-2-yl)-5-octyloxyphenol (BASF, Germany) 1wt%, light stabilizer 2,2,6,6-tetramethyl-4-piperidine stearate (Taiwan, China Double Bond Chemical Company) 1wt%, hydrolysis stabilizer P400 (Rheinland Chemical Company) 2.5wt%, anti-thermal oxygen aging agent triethylene glycol ether-two (3-tert-butyl-4-hydroxyl-5-methylbenzene Base) propionate (China Taiwan Yongguang Chemical Company) 0.5wt%. After mixing evenly, melt processing at 250-300°C.

[0066] The batching of gain layer is 85wt% of ethylene-propylene copolymer (Netherlands Liande Basel company), glycidyl methacrylate grafted polyethylene (Sartomer company) 5wt% and polyethylene glycol monomethacrylate (Manor Chemical Co., Ltd.) 5wt%, flaky talcum powder (Chuangyu Chemical Co., Ltd.) 1wt%, glass microspheres (3M Compa...

Embodiment 3

[0070] The backplane manufacturing process is as follows:

[0071] First, the substrate layer ingredients are polyethylene naphthalate (Changchun, Taiwan, China) 70wt%, glass fiber powder (Xiangu Technology Co., Ltd.) 21wt%, ultraviolet absorber 2-[4-[2-hydroxyl-3 -Dodecyloxypropyl]oxyl]-2-hydroxyphenyl]-4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine (Taiwan double bond Chemical Company) 0.54wt%, light stabilizer 2,2,6,6-tetramethyl-4-piperidine stearate (China Taiwan Double Bond Chemical Company) 0.459wt%, hydrolysis stabilizer type I (Germany Rheinland Chemical) 8wt%, anti-thermal oxygen aging agent 3,9-dioctadecyloxy-2,4,8,10-tetraoxo-3,9-diphosphospiro[5.5]undecane (Nanjing Hengqiao Chemical Company) 0.001 wt%. After mixing evenly, melt processing at 250-300°C.

[0072] The batching of gain layer is 89wt% of ethylene-octene copolymer (China Taiwan Fuju chemical company), 3wt% of maleic anhydride grafted polyethylene (Sartomer company) and triallyl isocyanurate (Jiangchang C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com