Preparation method for anionic linear copolymerized organic silicon softening and finishing agent

A softening finishing agent, anionic technology, applied in the field of preparation of anionic linear copolymer silicone softening finishing agent, can solve the problems of unusable dyeing system, low foam rate, stable work, etc., to improve compatibility and alkali resistance. Improve and overcome the "greasy effect"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

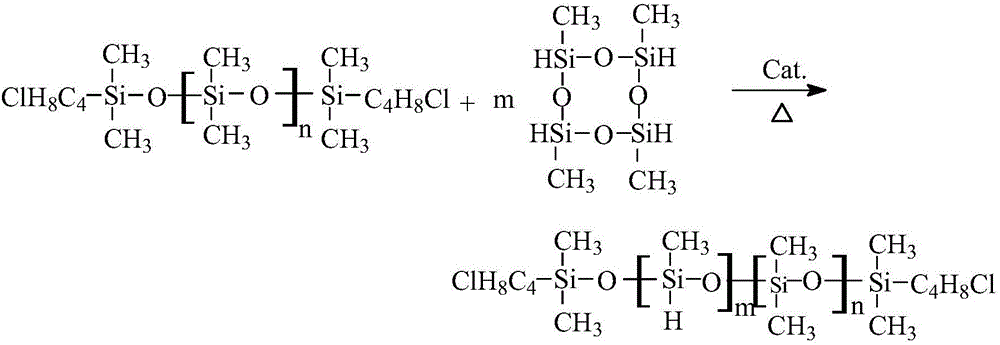

[0051] The preparation method of anionic linear copolymerization organosilicon softening agent, its steps are as follows:

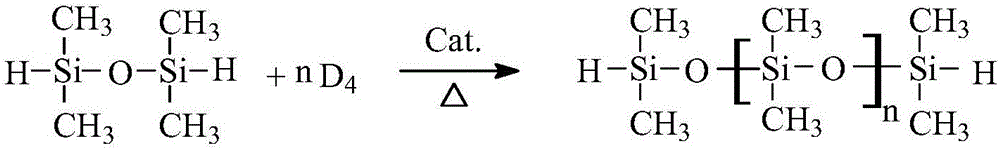

[0052] ⑴ Preparation of double-ended hydrogen-containing silicone oil

[0053] 1,1,3,3-Tetramethyldisiloxane and octamethylcyclotetrasiloxane and / or dimethylcyclotetrasiloxane at 1.0-10.0%: 90.0-99.0% (mass percentage) put into the stirred tank, add 1.0-3.0% of the acidic catalyst by the weight of the above two raw materials, stir and react for 3-9 hours at a temperature of 25-75°C, carry out the ring-opening chain extension reaction, remove the acidic catalyst, and then raise the temperature to 90 ~140°C vacuumizes to separate the low-boiling point substances to obtain double-ended hydrogen-containing silicone oil with a viscosity (25°C) of 100-1000 mpa.s, and its content is at least 95.0%.

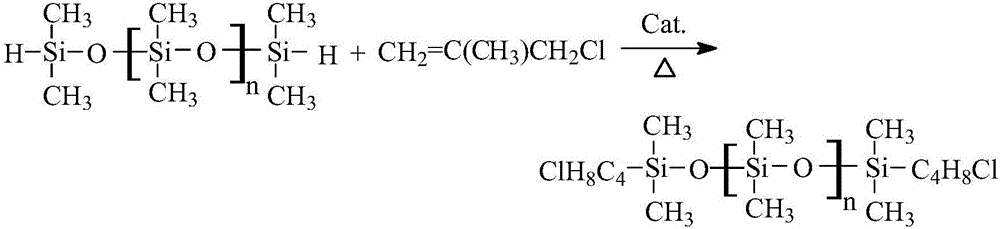

[0054] ⑵ Preparation of double-ended chlorine-containing silicone oil

[0055] The molar ratio of double-ended hydrogen-containing silicone oil and methallyl chlo...

Embodiment 1

[0067] ⑴ Preparation of double-ended hydrogen-containing silicone oil

[0068] Put 8 grams of 1,1,3,3-tetramethyldisiloxane and 190 grams of octamethylcyclotetrasiloxane into a 500ml four-neck round bottom flask, add 5 grams of concentrated sulfuric acid, Stir the reaction for 7-9 hours, carry out the ring-opening chain extension reaction, use the sedimentation method to remove the concentrated sulfuric acid, then raise the temperature to 90-140°C and vacuumize for 3-5 hours, separate the low boiling point substances, and obtain a viscosity (25°C) of 100-140mpa.s The content of double-ended hydrogen-containing silicone oil is 95.0-96.5%.

[0069] ⑵ Preparation of double-ended chlorine-containing silicone oil

[0070] 100 gram double-end hydrogen-containing silicone oils and 4.5 gram methallyl chlorides that step 1 makes are dropped in 250ml four-neck round-bottomed flasks, drop into 3 gram chloroplatinic acid alcohol solutions (10% mass percent isopropyl chloroplatinic acid ...

Embodiment 2

[0084] 100 grams of octamethylcyclotetrasiloxane (D 4 ) into 100 grams of dimethylcyclosiloxane (DMC), 5 grams of vitriol oil in step (1) and (3) are changed into 4 grams of trifluoromethanesulfonic acid, and undecylenic acid in step (4) is changed into dodecene acid, polyethylene glycol 600 in step (6) is replaced with polyether 600 (EO / PO mixed polymerization, wherein p=11, q=1), and the platinum catalyst in step (2) and (4) adopts polyether 600 in dimethylsiloxane For 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex, the solvent in step (7) isopropanol was changed to ethylene glycol butyl ether, and the rest were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com