Composite lithium ion battery separator and preparation method therefor

A technology of ion batteries and lithium composites, applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems that cannot be used alone, low strength of battery diaphragm, poor heat resistance, etc., and achieve easy market promotion and application, improve The effect of charging and discharging rate and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of a composite lithium-ion battery diaphragm, the preparation method comprising the following steps:

[0036] 1) Prepare polymethyl methacrylate polymer mixture: dissolve polymer resin in solvent, then add crosslinking agent, adhesive, defoamer and leveling agent in sequence, stir well, add initiator and continue stirring Uniformly, obtain polymethyl methacrylate polymer mixed solution;

[0037] 2) Preparation of the composite lithium-ion battery separator: immerse the non-woven fabric in the step 1) polymethyl methacrylate polymer mixture, then uniformly extract the non-woven fabric, and obtain the composite lithium-ion battery separator after drying.

[0038] As a further solution, in step 2) of the present invention, the non-woven fabric is soaked in the polymethyl methacrylate polymer mixture for 1s-600s, and then dried at 25-100°C for 0.5h-3h.

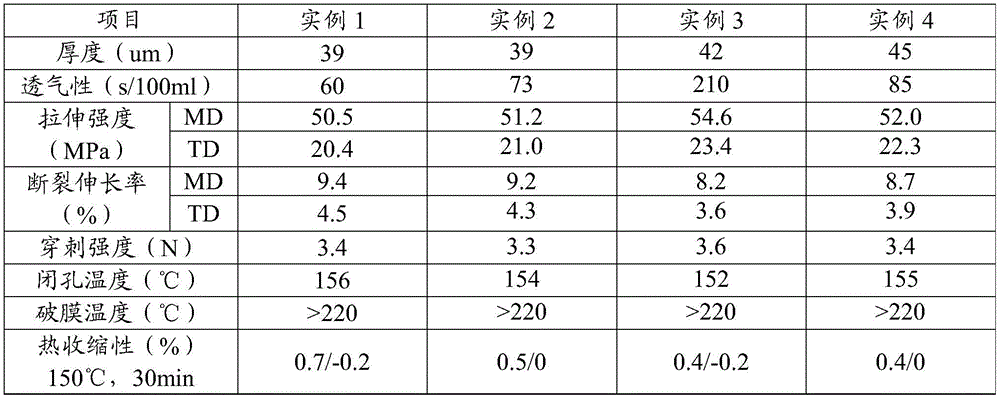

Embodiment 1

[0041] A composite lithium-ion battery diaphragm prepared by the following method:

[0042] 1) Weigh 628.5 parts of acetone and add 100 parts of PMMA pellets while stirring. After completely dissolving, add 52.37 parts of water and 52.37 parts of isopropanol. After stirring for 30 minutes, add 20 parts of TMPTA, 8.38 parts of adhesive, 8.38 parts 1 part of defoamer, 8.38 parts of leveling agent, after stirring for 30 minutes, add 1.0 part of BPO, and continue stirring for 10 minutes;

[0043] 2) Immerse the PET non-woven fabric in the above solution for 1 min, extract the PET non-woven fabric at a uniform speed, and then dry it with air at 70° C. for 2 hours to obtain a composite lithium-ion battery separator.

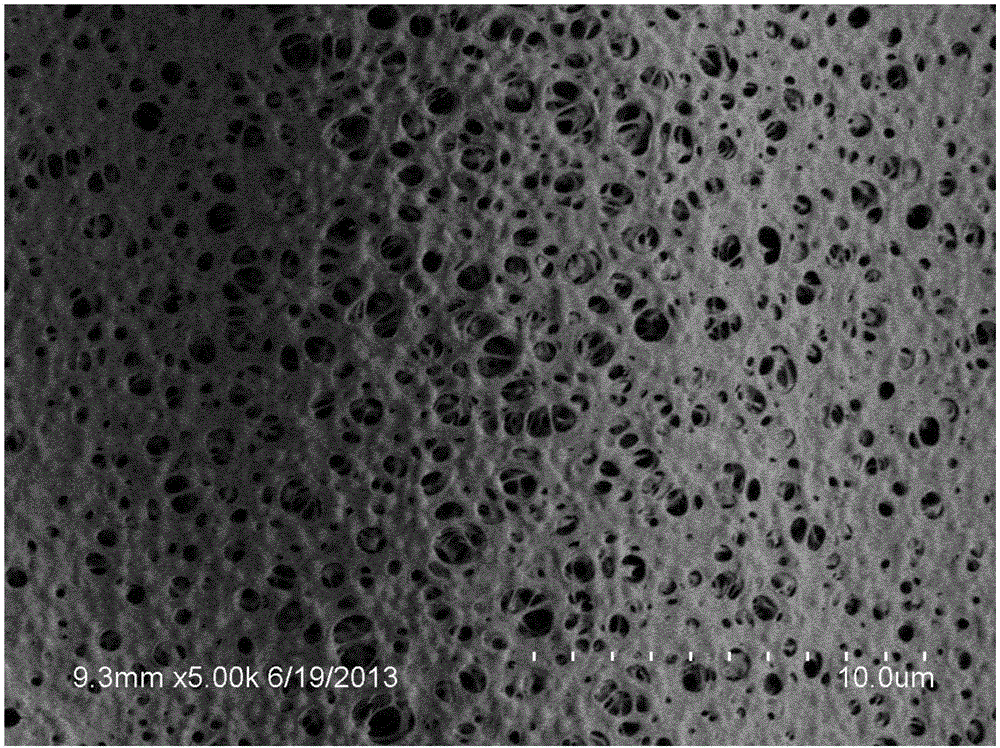

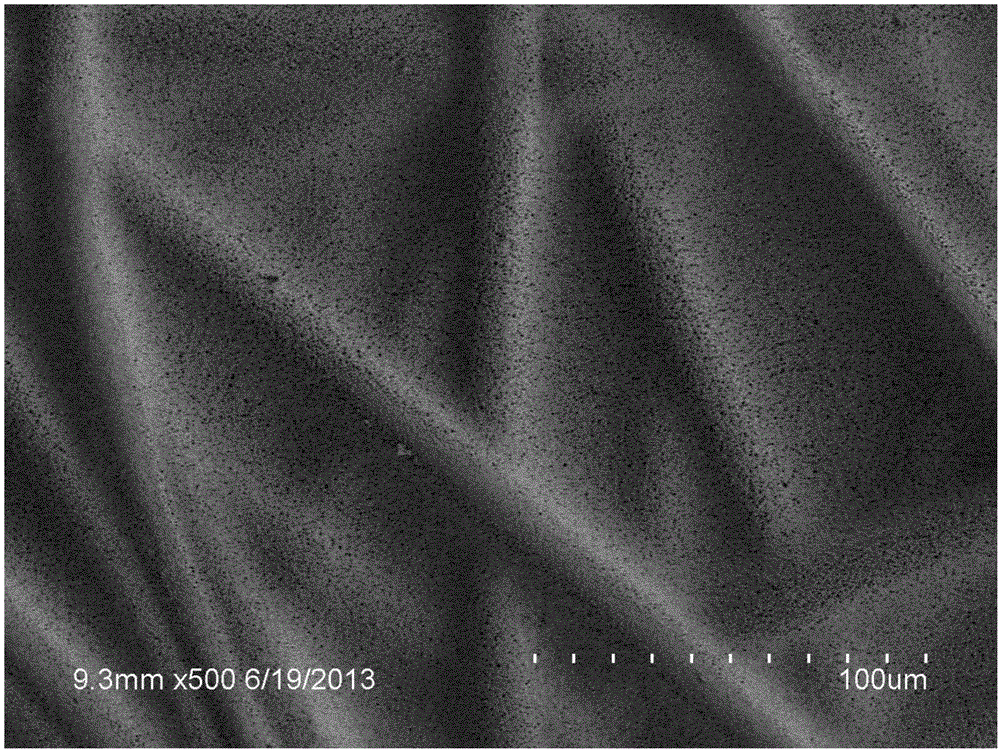

[0044] The composite lithium-ion battery diaphragm obtained in embodiment 1 is scanned and photographed with a Hitachi company model S4800 scanning electron microscope, and the photographed results can be found in figure 1 and figure 2 ,in figure 1 It is a 5000 tim...

Embodiment 2

[0046] A composite lithium-ion battery diaphragm prepared by the following method:

[0047] 1) Weigh 628.5 parts of tetrahydrofuran, and while stirring, add 90 parts of PMMA pellets and 10 parts of PVDF-HFP. After completely dissolving, add 52.37 parts of water and 52.37 parts of n-butanol. After stirring for 30 minutes, add 20 parts of TAIC, 8.38 part of adhesive, 8.38 part of defoamer, 8.38 part of leveling agent, after stirring for 30 minutes, add 0.678 part of AIBN, and continue stirring for 10 minutes;

[0048] 2) Immerse the PET non-woven fabric in the above solution for 1 min, extract the cellulose non-woven fabric at a uniform speed, and then dry it by air at 70°C for 2 hours, and then dry it in a vacuum oven at 70°C for 1 hour to obtain a composite lithium-ion battery separator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com