Preparation method for pure metal bismuth nanoparticles

A bismuth nano-metal technology, which is applied in the field of preparation of elemental metal bismuth nanoparticles, can solve the problems of short process flow and achieve the effects of simple preparation process, controllable time and easy acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples.

[0021] First weigh 3.525g of bismuth chloride dihydrate, 3.75g of tartaric acid, 10.25g of trisodium citrate, 7.35g of citric acid, 20.25g of glycerin and 18g of sodium chloride with an electronic balance, and measure 250ml of deionized water with a measuring cylinder Pour it into a beaker with a magnet, and place it on a magnetic stirrer to stir, then pour it into the beaker in the order of tartaric acid, citric acid, trisodium citrate, glycerin and sodium chloride and stir until it is completely dissolved. Or ammonia water to adjust the pH value of the solution so that the pH value of the solution is adjusted to 1.

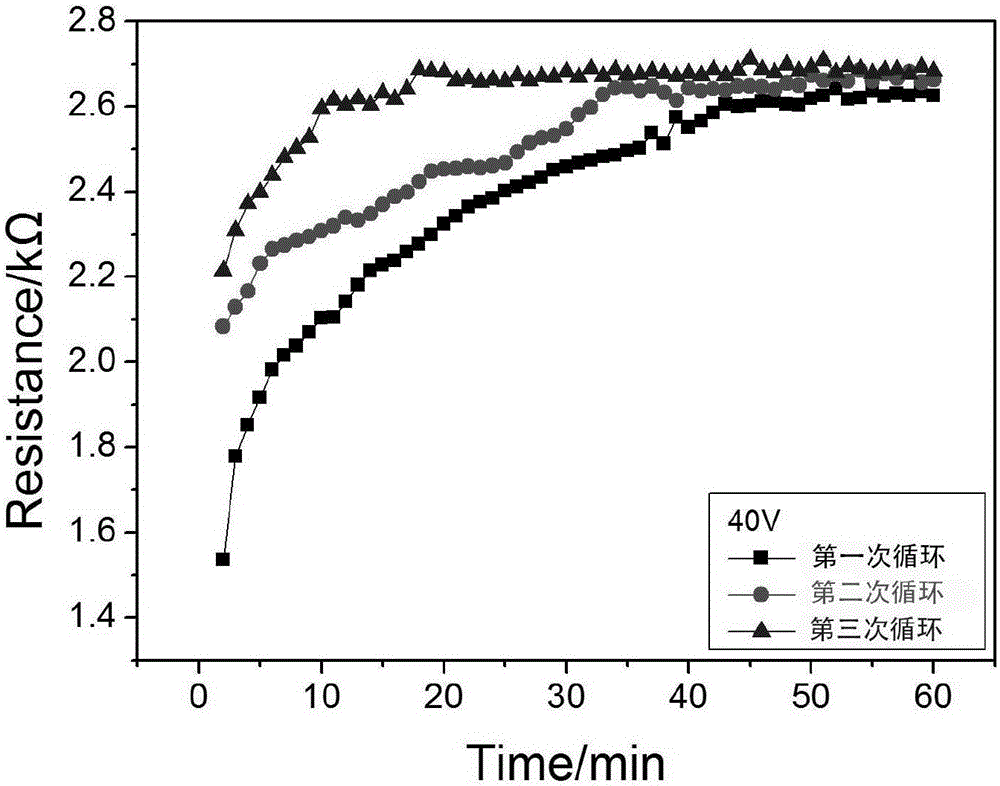

[0022] The graphite electrode is used as the anode material, the porous alumina template is used as the cathode material, and the prepared bismuth-containing chloride salt solution is used as the electrolyte, and is deposited for a long time at a constant temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com