A kind of high-temperature oxidation-resistant and wear-resistant Alcrn coating on the surface of titanium-aluminum alloy and preparation method thereof

A high-temperature oxidation-resistant, titanium-aluminum alloy technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of low bonding strength, low friction coefficient, low deposition rate, etc., and achieve oxidation resistance Strong, uniform and dense structure, to achieve the effect of coating components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

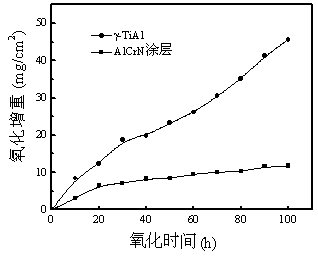

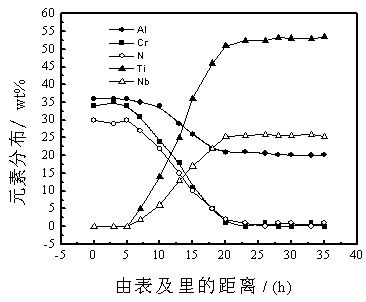

[0035] like figure 1 As shown in the figure, an AlCrN coating with high temperature oxidation resistance and wear resistance on the surface of titanium aluminum alloy is deposited on the surface of titanium aluminum alloy workpiece by double-glow plasma surface technology. The coating surface is an AlCrN deposition layer with a thickness of 7 microns. Formation of dense Al-rich 2 O 3 and the oxide layer of Cr oxide; the inside of the coating is an AlCrN diffusion layer with a thickness of 12 microns.

[0036] Aluminium-rich deposits form dense Al at high temperatures 2 O 3 The oxide film prevents the matrix from being further oxidized, and solves the problem of poor oxidation resistance of the γ-TiAl alloy at high temperatures above 700°C. The internal AlCrN diffusion layer has no sudden change in composition. Under the strong thermal shock such as the hot end of the engine, micro-cracks are not easily generated, so the reliability is high; the diffusion layer is metallurg...

Embodiment 2

[0047] An AlCrN coating with high temperature oxidation resistance and wear resistance on the surface of titanium aluminum alloy, which is deposited on the surface of titanium aluminum alloy workpiece by double-glow plasma surface technology. Al rich 2 O 3 and the oxide layer of Cr oxide; the inside of the coating is an AlCrN diffusion layer with a thickness of 13 microns.

[0048] The preparation method includes the following steps:

[0049] (1) Furnace loading: Load the γ-TiAl workpiece and AlCr target into the double-glow plasma surface alloying furnace, take the γ-TiAl workpiece as the workpiece pole, the AlCr target as the source electrode, and the distance between the source electrode and the workpiece electrode is 10mm , the composition ratio of AlCr target material is: Al accounts for 50wt%, and the balance is Cr;

[0050] (2) Vacuuming: close the furnace body and the air inlet, open the cooling water, open the vacuum pump and vacuumize until the pressure in the fur...

Embodiment 3

[0057] A high-temperature oxidation-resistant and wear-resistant AlCrN coating on the surface of titanium aluminum alloy, which is deposited on the surface of titanium aluminum alloy workpiece by double-glow plasma surface technology. The surface of the coating is an AlCrN deposition layer with a thickness of 10 microns. Al rich 2 O 3 and the oxide layer of Cr oxide; the inside of the coating is an AlCrN diffusion layer with a thickness of 15 microns.

[0058] The preparation method includes the following steps:

[0059] (1) Furnace loading: Ti 2 The AlNb-based alloy workpiece and AlCr target were loaded into the double-glow plasma surface alloying furnace, and the Ti 2 The AlNb-based alloy workpiece is the workpiece pole, the AlCr target is the source electrode, the distance between the source electrode and the workpiece electrode is 50mm, the AlCr target material composition ratio is: Al accounts for 80wt%, and the balance is Cr;

[0060] (2) Vacuuming: close the furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com