Capillary ceramic body as well as manufacturing method and application thereof

A capillary, ceramic body technology, applied in the field of ceramic materials, can solve the problems of unsatisfactory wear resistance, short service life, blocking wear resistance, etc., and achieve long service life, improved wear resistance and strength, and improved machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

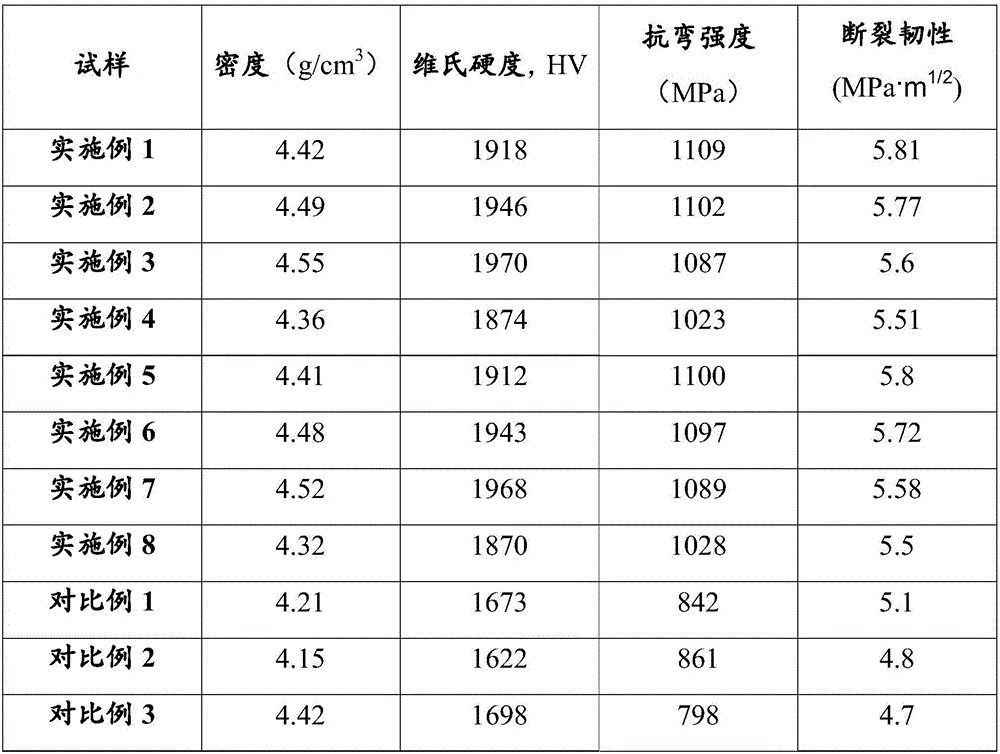

Examples

preparation example Construction

[0033] In one embodiment, the preparation method of the capillary ceramic body of the embodiment of the present invention includes the following steps:

[0034] Step S01: According to the above-mentioned components contained in the capillary ceramic body of the embodiment of the present invention, the raw materials of each component are weighed in proportion, and the raw materials of each component are mixed to obtain a ceramic mixed powder;

[0035] Step S02: mixing the organic monomer, cross-linking agent and dispersant with water to obtain a pre-mixed liquid, and then adding the ceramic mixed powder into the pre-mixed liquid for mixing treatment to prepare a ceramic slurry;

[0036] Step S03: adding an initiator and a catalyst to the ceramic slurry, forming and drying to obtain a green body;

[0037] Step S04: Sintering the green body in a vacuum protective atmosphere, and then performing hot isostatic pressing to obtain a capillary ceramic body.

[0038] Specifically, in ...

Embodiment 1

[0074] Embodiment 1 provides a capillary ceramic body and a preparation method thereof. The capillary ceramic body contains the following components in mass percentage:

[0075] 75.5% alumina powder, 24% nano zirconia, 0.5% submicron ceramic powder.

[0076] The preparation method of the capillary ceramic body is as follows:

[0077] (1): According to the components contained in the capillary ceramic body in this embodiment 1, weigh alumina powder, nano-zirconia and submicron ceramic powder according to the proportion, and mix the corresponding raw materials to obtain a ceramic mixed powder;

[0078] (2): Fully mix the organic monomer, cross-linking agent and dispersant with water to obtain the pre-preparation solution, and adjust the pH value of the pre-preparation solution to 9-10, and then mix the ceramic mixed powder obtained in the above step (1) Add it into the pre-mixed liquid for mixing, and ball mill at a speed of 150 rpm for 15-20 hours to obtain a ceramic slurry. ...

Embodiment 2

[0084] Embodiment 2 provides a capillary ceramic body and a preparation method thereof. The capillary ceramic body contains the following components in mass percentage:

[0085] 70% alumina powder, 27% nano zirconia, 3% submicron ceramic powder.

[0086] The preparation method of the capillary ceramic body is as follows:

[0087] (1): According to the components contained in the capillary ceramic body in Example 2, weigh alumina powder, nano-zirconia and submicron ceramic powder according to the proportion, and mix the corresponding raw materials to obtain a ceramic mixed powder;

[0088] (2): Fully mix the organic monomer, cross-linking agent and dispersant with water to obtain the pre-preparation solution, and adjust the pH value of the pre-preparation solution to 9-10, and then mix the ceramic mixed powder obtained in the above step (1) Add it into the pre-preparation solution for mixing, and ball mill at a speed of 200 rpm for 15-20 hours to obtain a ceramic slurry. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com