Konjac fly powder based epoxy resin, preparation method thereof and coating prepared from konjac fly powder based epoxy resin

A technology of konjac flying powder and epoxy resin, which is applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as threats to the health of living bodies, and achieve the effects of accelerating curing time, high mechanical strength, and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Take 100 grams of konjac powder and 600 g of phenol into a 1500 ml three-neck flask equipped with a condenser and a stirrer, stir at 100 ° C and add 3 g of concentrated sulfuric acid dropwise, react for 2 hours, cool to room temperature, filter, and the residue rate is 3.8% . The filtrate is neutralized with anhydrous magnesium oxide, filtered, and the unreacted phenol is removed under reduced pressure to obtain the liquefaction product of konjac flying powder.

Embodiment 2

[0044] Add 100g of the liquefied product of konjac flying powder, 185g of epichlorohydrin and 1g of tetrabutylammonium bromide to a four-necked flask equipped with electric stirring, condenser, thermometer and dropping funnel, react at 120°C for 4h, and reduce Remove unreacted epichlorohydrin under pressure. Add 500ml of toluene to the remaining product to dissolve, add 84g of 30% sodium hydroxide aqueous solution dropwise at room temperature, continue the reaction for 4h after the dropwise addition, filter after the reaction, wash the filtrate with deionized water until neutral, dry and remove the solvent under reduced pressure That is to obtain konjac flying powder-based epoxy resin with an epoxy value of 0.29 and a viscosity of 3000-4000 cps (25° C.).

Embodiment 3

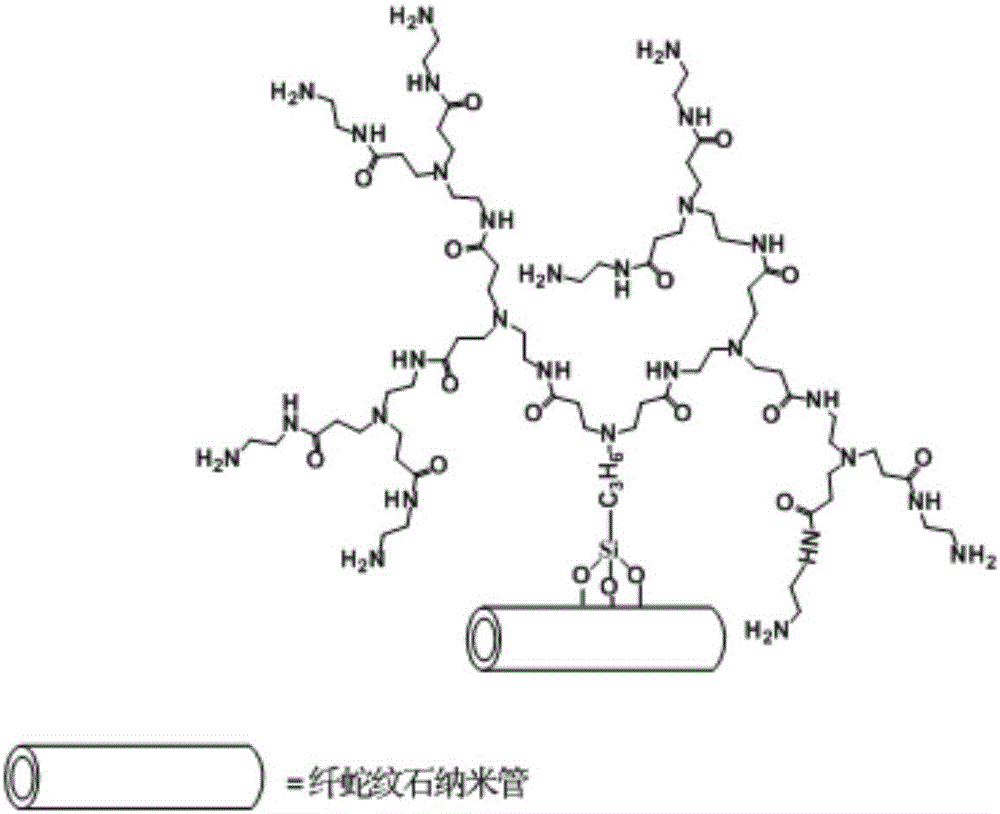

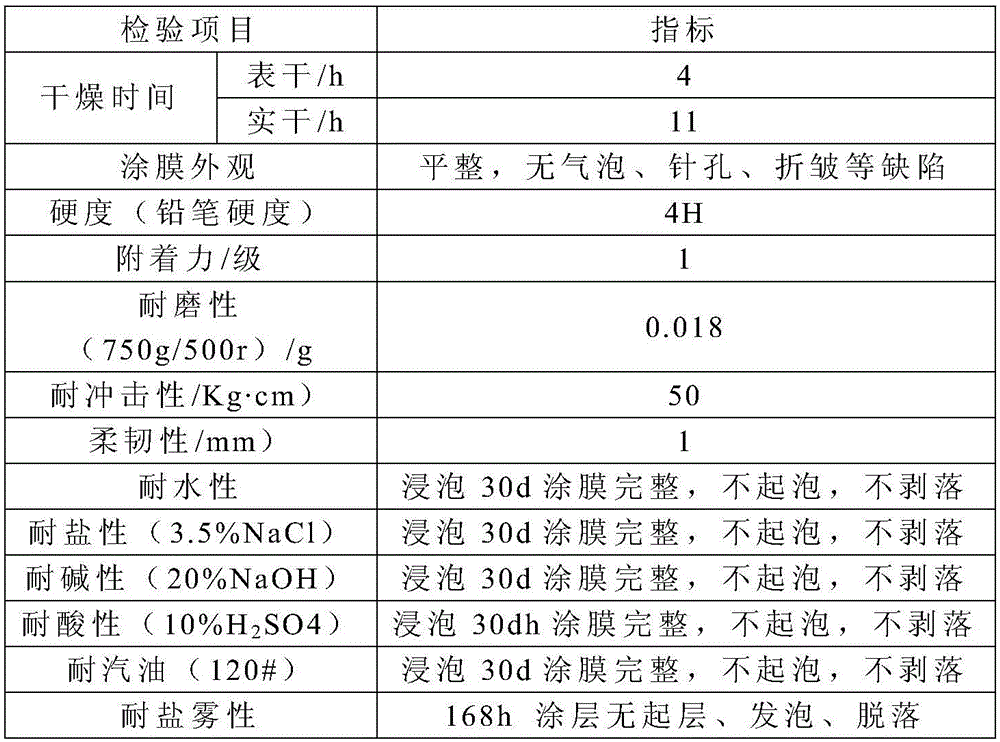

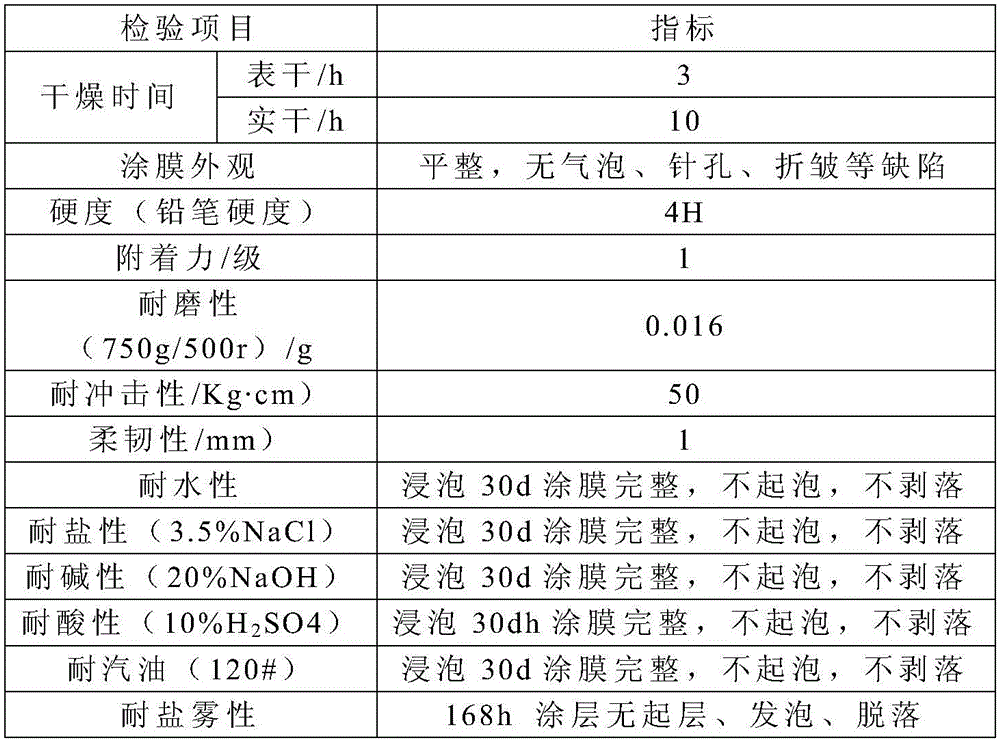

[0046] Konjac fly powder epoxy resin 100g obtained by the method of embodiment 2, modified serpentine nanotube 5g, bisphenolic acid type hyperbranched epoxy resin (HBPE-1, performance is shown in Table 1) 5g, cardanol base Add 15g of epoxy glycidyl ether into the disperser. After the resin is evenly dispersed, add 0.3g of wetting and dispersing agent TEGODispers710, 0.5g of leveling agent TEGOGlide411, 0.5g of defoamer TEGOAirex931, and then disperse evenly, then add 10g of quartz powder, 5g of titanium dioxide and 5g of ultra-fine mica powder are uniformly dispersed at high speed, sanded by a sand mill to reach the required fineness (50μm) and discharged to obtain component A.

[0047] Then, add 100 g of cardanol phenalkamine curing agent (ie, component B) to component A, mix and stir evenly, and obtain the solvent-free room temperature curing nano-anticorrosion coating of the present invention. The anti-corrosion coating film has fast drying time, strong adhesion, good flexi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com