Method of preparing copper-zinc-copper composite coating with high corrosion resistance on surface of low-carbon steel

A technology of high corrosion resistance and composite coating, applied in the field of anti-corrosion treatment of metal material surface, can solve the problems of poor corrosion resistance, uneven coating, many pores, etc., to improve corrosion resistance, fast electrodeposition, simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

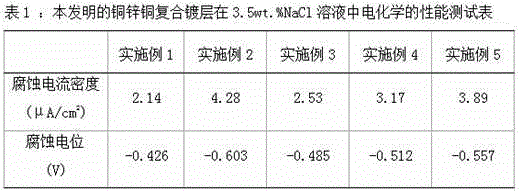

Examples

Embodiment 1

[0016] A method for preparing a highly corrosion-resistant copper-zinc-copper composite coating on the surface of low-carbon steel of the present invention is characterized in that the method steps include:

[0017] (1). Degreasing the surface of low carbon steel: first prepare a degreasing solution with a concentration of 30g / LNaOH and 10g / L zinc powder, heat it to 35-50°C, and put the low carbon steel into the above degreasing solution Carry out degreasing, the degreasing time is 20-40min, take it out, then rinse with deionized water, then remove the residue of surface oxide, rinse with deionized water, and obtain the pretreated low carbon steel;

[0018] (2). The low carbon steel after the above-mentioned step (1) pretreatment is carried out pulse copper-plating electroplating treatment: first prepare pulse copper-plating electroplating solution; The component of described pulse copper-plating electroplating solution is: copper sulfate 100g / L, sulfuric acid 20g / L, sodium ch...

Embodiment 2

[0024] Present embodiment 2 is basically the same as above-mentioned embodiment 1 method, and difference is, the step (2) described in present embodiment 2 described in step (2) to the preparation pulse copper-plating electroplating solution, galvanized electroplating solution, The components of alkaline copper-plating electroplating solution, copper-plating electroplating solution and their electroplating process parameters are as follows:

[0025] Pulse copper-plating electrolyte components described in step (2): copper sulfate 200g / L, sulfuric acid 40g / L, sodium chloride 0.02g / L, 209 cylinder opener A0.3ml / L, 209 cylinder opener B0 .3ml / L, 209 cylinder opening agent C8.0ml / L; electroplating process parameters: electroplating current intensity: 4A / dm 2 , temperature: 35°C, plating time: 10min;

[0026] Components of the galvanized electroplating solution described in step (3): zinc sulfate 220g / L, boric acid 16g / L, SZ-97 brightener 16ml / L; electroplating process parameters:...

Embodiment 3

[0030] Present embodiment 3 is basically the same as above-mentioned embodiment 1 method, difference is, the preparation pulse copper-plating electroplating solution, galvanized electroplating solution, The components of alkaline copper-plating electroplating solution, copper-plating electroplating solution and its electroplating process parameters are as follows: the pulse copper-plating electroplating solution component described in step (2): copper sulfate 220g / L, sulfuric acid 55g / L, chlorine Sodium chloride 0.03g / L, 209 cylinder opener A0.5ml / L, 209 cylinder opener B0.5ml / L, 209 cylinder opener C9.0ml / L; electroplating process parameters: electroplating current intensity: 8A / dm 2 , temperature: 20°C, plating time: 10min;

[0031] The components of the galvanized electroplating solution described in step (3): zinc sulfate 250g / L, boric acid 15g / L, SZ-97 brightener 15ml / L; electroplating process parameters: electroplating current intensity: 3A / dm 2 , temperature: 25°C, pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com