Preparation method of polyimide fibers containing symmetric bispyrimidine structures

A technology of polyimide fiber and bispyrimidine, which is applied in the field of preparation of polyimide fiber with symmetrical bispyrimidine structure, can solve the problems of difficult removal of polar solvents and degradation of physical and chemical properties of materials, and achieve high performance , excellent mechanical properties, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

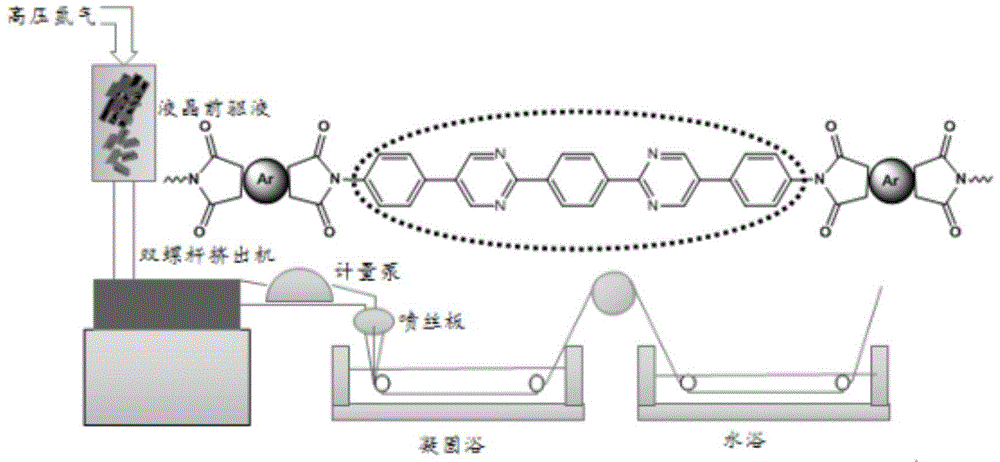

Method used

Image

Examples

Embodiment 1

[0027] Under nitrogen protection, 500gP 2 o 5 Add polyphosphoric acid with a content of 80% into a 1L reactor, heat to 150°C and stir for 1.5 hours to obtain a clear polyphosphoric acid solution.

[0028] Add successively 62.4g (0.15mol) of diamine monomer 2,2'-(1,4-phenylene)bis[5-(4-aminophenyl)]pyrimidine, 20g of anhydrous stannous chloride, 48.3g (0.15mol) of 3,3',4,4'-benzophenonetetraacid dianhydride (BTDA), and add 166g of P 2 o 5 , the mass of diamine and dianhydride accounts for 14.2% of the total mass of the reaction system, P 2 o 5 The quality accounts for 85% of the polyphosphoric acid solution quality. The temperature was raised, and the reaction system was reacted at 180° C. for 5 hours, and at 220° C. for 5 hours to obtain a liquid crystal polyimide spinning solution. The solution is yellow and transparent, with an intrinsic viscosity of 1.77dL / g (concentrated sulfuric acid as a solvent, measured at 25°C).

[0029] The liquid crystal spinning stock soluti...

Embodiment 2

[0032] Under nitrogen protection, 500gP 2 o 5 Add polyphosphoric acid with a content of 80% into a 1L reactor, heat to 150°C and stir for 1.5 hours to obtain a clear polyphosphoric acid solution.

[0033]Add successively 58.2g (0.14mol) of diamine monomer 2,2'-(1,4-phenylene)bis[5-(4-aminophenyl)]pyrimidine, 18g of anhydrous stannous chloride, 41.1g (0.14mol) of 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA), and added 269gP 2 o 5 . The quality of diamine and dianhydride accounts for 11.4% of the total mass of the reaction system, P 2 o 5 The quality accounts for 87% of the polyphosphoric acid solution quality. Then the temperature was raised, and the reaction system was reacted at 190° C. for 4 hours and 230° C. for 5 hours to obtain a liquid crystal polyimide spinning solution. The solution is yellow and transparent, with an intrinsic viscosity of 2.21dL / g (concentrated sulfuric acid is used as a solvent, measured at 25°C).

[0034] The liquid crystal spinning ...

Embodiment 3

[0037] Under nitrogen protection, 500gP 2 o 5 Add polyphosphoric acid with a content of 80% into a 1L reactor, heat to 150°C and stir for 1.5 hours to obtain a clear polyphosphoric acid solution.

[0038] Add successively 70.4g (0.17mol) of diamine monomer 2,2'-(1,4-phenylene)bis[5-(4-aminophenyl)]pyrimidine, 25g of anhydrous stannous chloride, 37.1g (0.14mol) of pyromellitic dianhydride (PMDA) and 240g of P 2 o 5 To the reaction system, the quality of diamine and dianhydride accounts for 12.7% of the total mass of the reaction system, P 2 o 5 Accounting for 86.5% of the total mass of polyphosphoric acid solution. The temperature was raised, and the reaction system was reacted at 175° C. for 5 hours, and at 220° C. for 5 hours to obtain a liquid crystal polyimide spinning solution. The solution is yellow and transparent, with an intrinsic viscosity of 2.05dL / g (concentrated sulfuric acid as a solvent, measured at 25°C).

[0039] The liquid crystal spinning stock solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com