Cellulose-based phenolic compound molecularly imprinted adsorbent and preparation method thereof

A phenolic compound, molecular imprinting technology, applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc. Adsorption performance, simple production process, and the effect of realizing high-value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

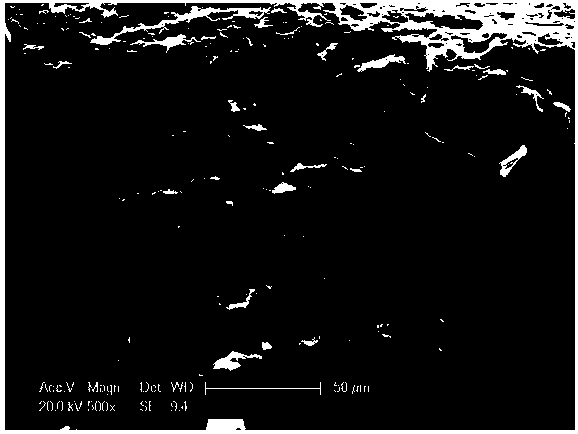

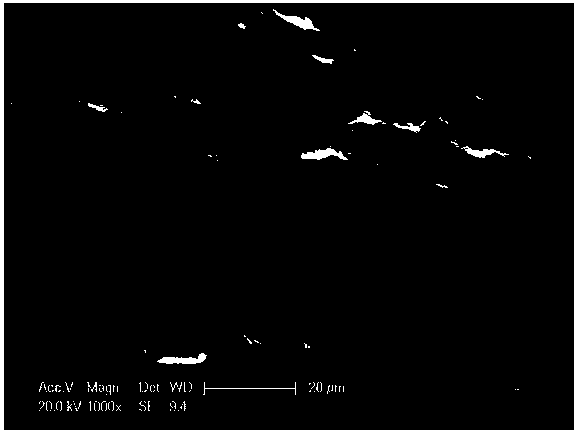

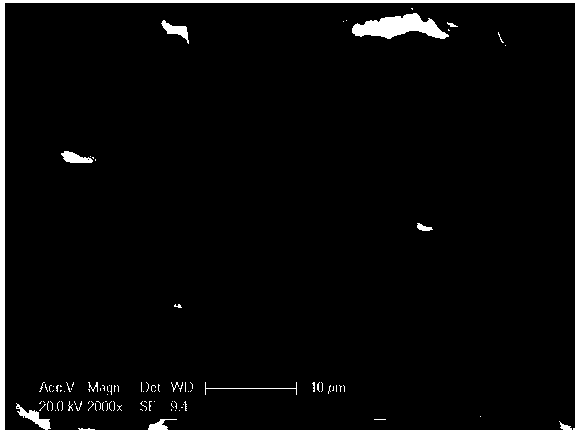

Image

Examples

Embodiment 1

[0088] The raw material components used in this embodiment are as follows:

[0089] Absorbent cotton: 0.62 kg;

[0090] Cellulose dissolving agent ([Bmim]Cl and dimethyl maple, the volume ratio of the two is 5:1): 24.8 kg;

[0091] Chloroacetyl chloride: 4.13 kg;

[0092] Cuprous bromide: 1.2 kg;

[0093] 2,2'-bipyridine: 1.26 kg;

[0094] Ascorbic acid: 0.36 kg;

[0095] Chloroform: 37.17 kg;

[0096] Methacrylic acid: 20.23 kg;

[0097] 2-Chlorophenol: 10.23 kg;

[0098] The specific steps are:

[0099] (1) Cellulose dissolution

[0100] 0.62 kg of pulverized absorbent cotton and 24.8 kg of cellulose dissolving agent were uniformly mixed, and stirred and dissolved at 80° C. for 1 hour under microwave-assisted conditions to obtain a homogeneous cellulose solution;

[0101] (2) Cellulose homogeneous esterification modification

[0102] Add 4.13 kg of chloroacetyl chloride to the cellulose homogeneous solution, adjust the temperature to 40°C, and stir for 1 hour. Afte...

Embodiment 2

[0125] The raw material components used in this embodiment are as follows:

[0126] Absorbent cotton: 0.89 kg;

[0127] Cellulose dissolving agent ([Emim]Cl and N,N dimethylformamide, 3:1): 35.61 kg;

[0128] Bromoisoacyl bromide: 5.46 kg;

[0129] Cuprous chloride: 3.01 kg;

[0130] N, N, N', N', N"-pentamethyldiethylenetriamine: 0.82 kg;

[0131] Stannous octoate: 1.04 kg;

[0132] Toluene: 23.81 kg;

[0133] 4-vinylpyridine: 18.49 kg;

[0134] 4-Chlorophenol: 10.87 kg;

[0135] The specific steps are:

[0136] (1) Cellulose dissolution

[0137] 0.89 kg of pulverized absorbent cotton and 35.61 kg of cellulose dissolving agent were uniformly mixed, and stirred and dissolved at 80° C. for 2 hours under microwave-assisted conditions to obtain a homogeneous cellulose solution;

[0138] (2) Cellulose homogeneous esterification modification

[0139] Add 5.46 kg of bromoisoacyl bromide to the cellulose homogeneous solution, adjust the temperature to 40°C, and stir for 2 h...

Embodiment 3

[0162] The raw material components used in this embodiment are as follows:

[0163] Masson pine pulp: 0.48 kg;

[0164] Cellulose dissolving agent ([Amim]Cl and N,N dimethylacetamide, 2:1): 19.2 kg;

[0165] 2-bromoisobutyryl bromide: 2.82 kg;

[0166] Nail bromide: 2.69 kg;

[0167] 2-Pyridine formaldehyde n-propylamine: 1.39 kg;

[0168] Vitamin C: 1.25 kg;

[0169] n-heptane: 23.59 kg;

[0170] 2-vinylpyridine: 24.26 kg;

[0171] 2-Nitrophenol: 24.32 kg;

[0172] The specific steps are:

[0173] (1) Cellulose dissolution

[0174] Uniformly mix 0.48 kg of masson pine pulp with 19.2 kg of cellulose dissolving agent, and stir and dissolve at 80° C. for 2 hours under microwave-assisted conditions to obtain a homogeneous cellulose solution;

[0175] (2) Cellulose homogeneous esterification modification

[0176] Add 2.82 kg of 2-bromoisobutyryl bromide to the cellulose homogeneous solution, adjust the temperature to 40°C, and stir for 2 hours. After the reaction, pour i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com