Platy-monocrystal alpha-aluminum oxide, and preparation method and application thereof

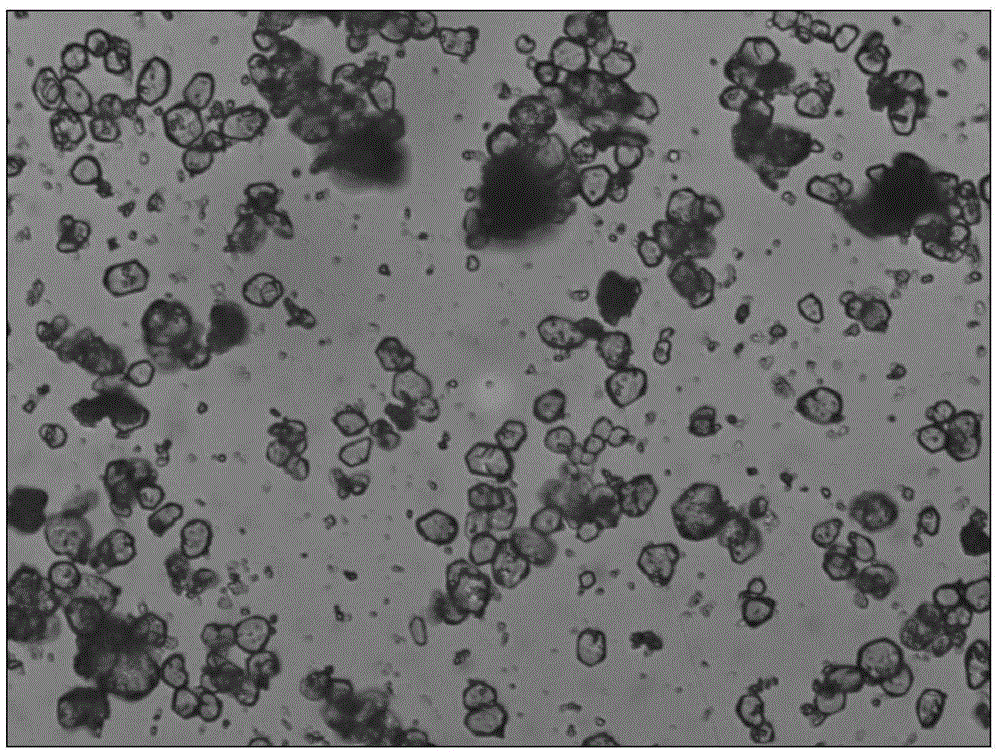

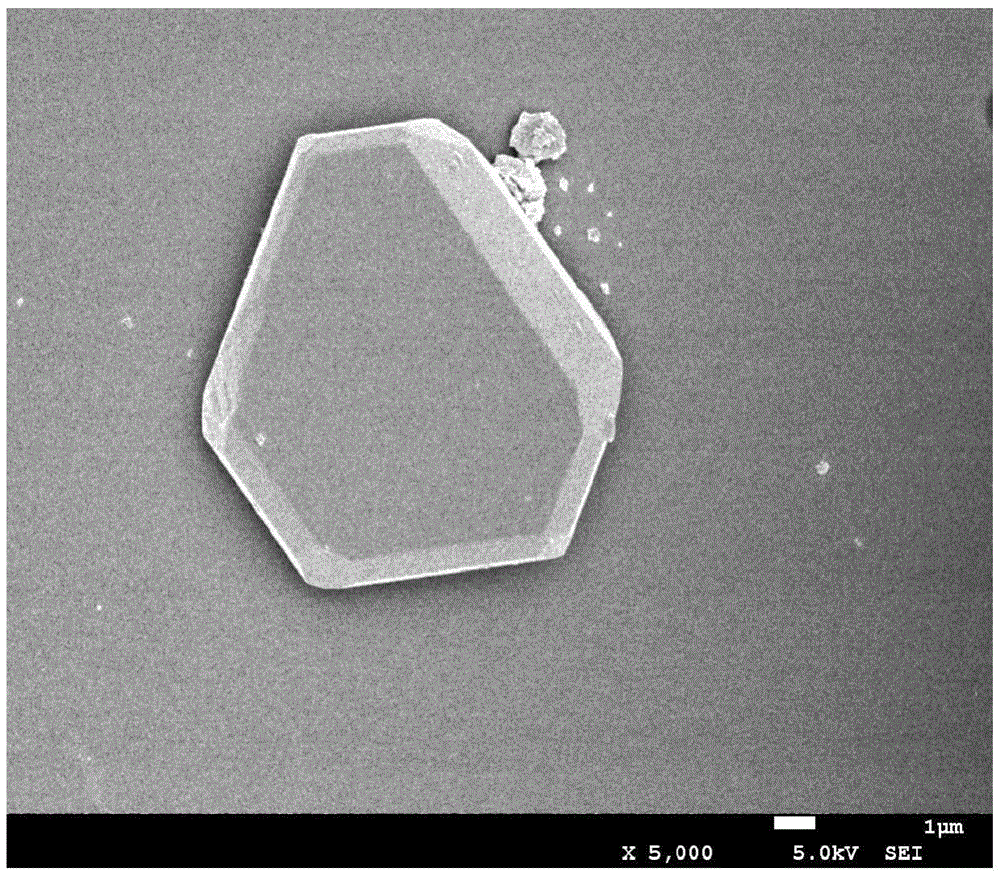

A flaky single crystal and alumina technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, inorganic chemistry, etc., can solve problems such as high pre-calcination or calcination temperature, complex production process, and difficult tail gas treatment. Achieve the effects of uniform size, simplified process flow and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

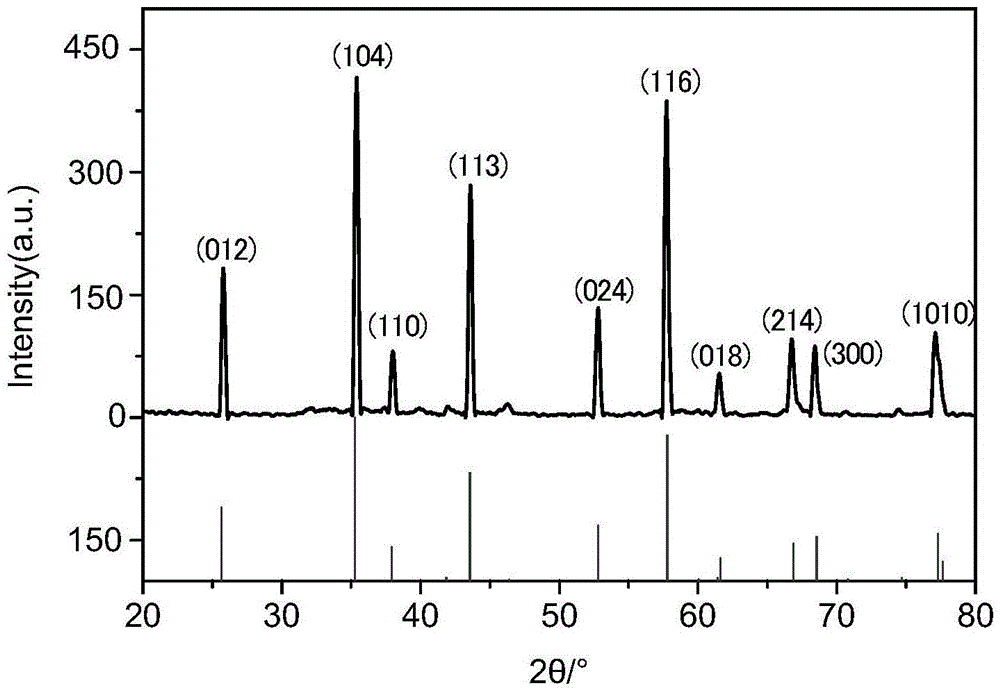

[0039] A kind of preparation method of flaky single crystal α-alumina of the present invention comprises the following steps:

[0040] a. Using aluminum hydrate or transition phase alumina as raw material, add molten salt, mix and grind; according to the weight ratio, aluminum hydrate or transition phase alumina: molten salt added = 1:1~10;

[0041] b. Add fluoride to the ground material in step a, grind and mix uniformly to obtain a mixed material; wherein, the amount of fluoride added is 1 to 50% of the weight of the generated α-alumina;

[0042] c. Heat the mixed material obtained in step b to 700-1200°C at a rate of 1-20°C / min, keep it warm for 0.5-4h, and cool to room temperature;

[0043] d. Dissolving the material obtained after cooling in step c with hot water at 60-100°C, washing and filtering;

[0044] e. Repeat step d until all the molten salt is removed and dried to obtain flaky single crystal α-alumina.

[0045] The present invention reduces the melt viscosity o...

Embodiment 1

[0061] Weigh 10 g of aluminum monohydrate boehmite (Boehmite, AlOOH) and pseudo boehmite (pseudoBoehmite, AlOOH) 10 g into a mortar, then weigh 10 g of lithium chloride (LiCl) and 0.6 g of NH 4 F, after grinding and mixing evenly, transfer to corundum crucible for calcination. After heating up to 700°C at a rate of 6°C / min, keep the temperature for 4 hours, and then cool down to room temperature with the furnace to obtain the synthesized product. The obtained synthetic product was dissolved in hot water, then filtered and washed with distilled water several times to remove residual molten salt, and finally dried to obtain flaky α-alumina.

Embodiment 2

[0063] Weigh aluminum sulfate crystal salt (Al 2 (SO 4 ) 3 .18H 2 O) 66.6g was dissolved in 200g distilled water, and 41g of 25% ammonia water was added to precipitate under vigorous stirring to obtain aluminum hydroxide gel. After washing with water to remove ammonium sulfate, add 1560 g of sodium sulfate to the obtained aluminum hydroxide gel, then add 1.56 g of LiF, ball mill for 2 hours, mix well, and put it into a corundum crucible for calcination. After heating up to 1200°C at a rate of 300°C / h, keep the temperature for 1 hour, and then cool down to room temperature with the furnace to obtain the synthesized product. The obtained synthetic product was dissolved in hot water, then filtered and washed with distilled water several times to remove residual molten salt, and finally dried to obtain flaky α-alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com