Biodegradable heat-resistant sheet and preparation method thereof

A biodegradable and heat-resistant technology, applied in the field of biodegradable heat-resistant sheet and its preparation, can solve the problems of calendered product cost and difficult commercialization, limited application range, poor heat resistance, etc., and achieve excellent physical and mechanical properties, Wider range of applications and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

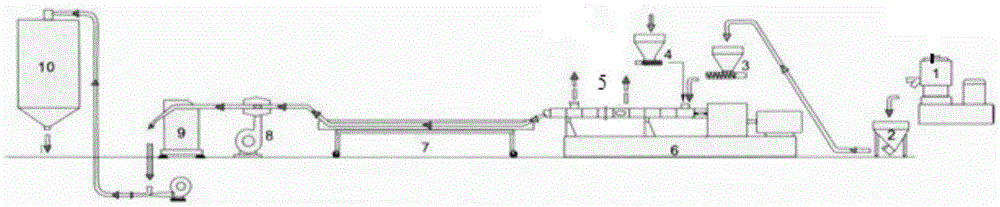

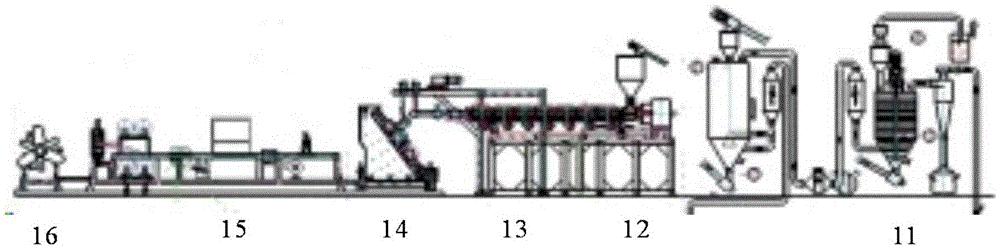

Method used

Image

Examples

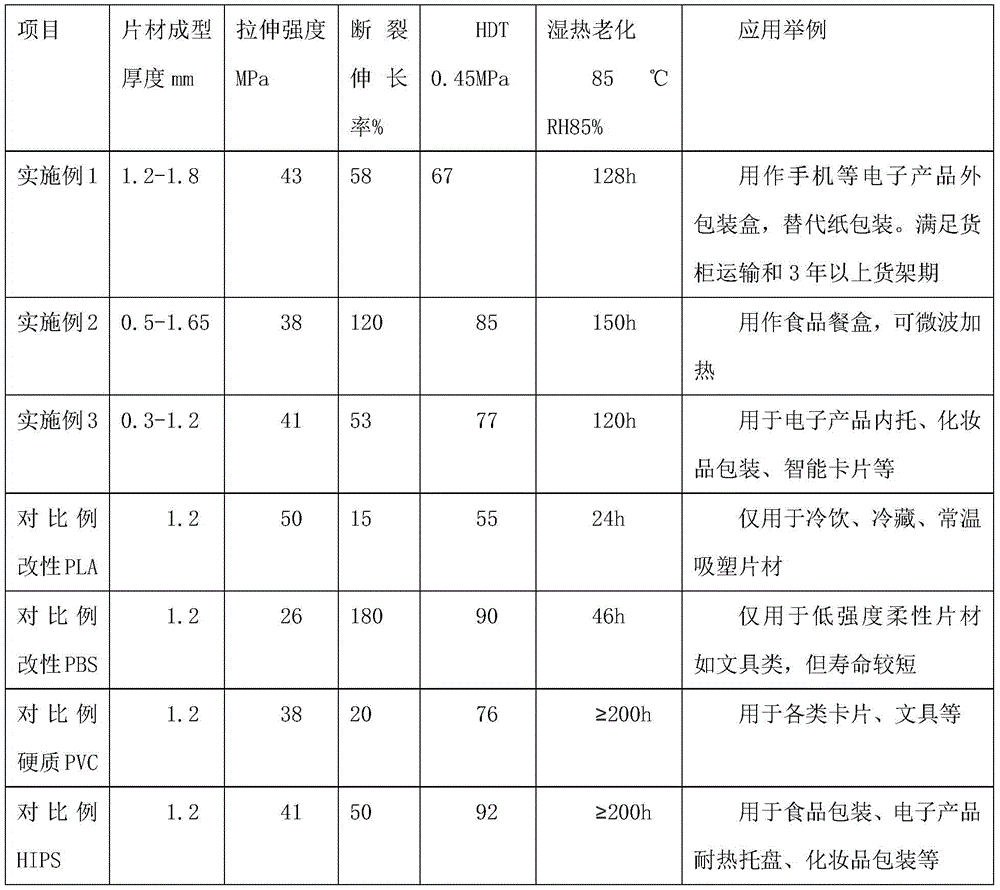

Embodiment 1

[0047] By weight percentage, add 3% of 8000 mesh talc powder, 2% of titanium dioxide, 0.75% of PE wax, 0.5% of calcium stearate, 0.5% of BASF chain extender, 0.1% of 10100.1%, and 1.15% of carboimide into a high-speed mixer at 40°C for mixing After 20 minutes, put it in No. B weight loss meter for later use. After dehumidifying and drying P3HB4HB10%, PBS37%, and polylactic acid 45% with 4HB content of 6%, add it to a high-speed mixer and mix it at room temperature for 15 minutes. At the same time, it enters the twin-screw extruder for melt blending, water-stretched granulation, and can be used to prepare various sheets and other products. Dry the above resin and add it to a sheet extruder with a screw diameter of 130mm, and prepare a 1.0-1.8mm thick sheet at an extrusion temperature of 160-195°C and an extrusion speed of 40rpm, which has excellent appearance and good Comprehensive performance.

Embodiment 2

[0049] By weight percentage, 10000 mesh talcum powder 8%, 6000 mesh mica 3%, EBS0.5%, zinc stearate 0.5%, titanate coupling agent 0.2%, 10100.1%, phosphite antioxidant 0.1 %, UV5270.3%, carboimide 0.3%, add high-speed mixer at 50°C and mix for 20 minutes, then put it in No. B weight loss meter for later use, add PHBV5%, PBS40%, polylactic acid 40%, PBAT2% with HV content of 10% After mixing in a high-speed mixer at room temperature for 10 minutes, place the No. A weight loss meter, and enter the twin-screw extruder for melt blending with the No. B compound at the same time, and water-cooled strands for granulation. It can be used to prepare various sheets and other products. Dry the above resin and add it to a sheet extruder with a screw diameter of 130mm, and prepare a 0.5-1.65mm thick sheet at an extrusion temperature of 160-185°C and an extrusion speed of 30rpm, which has excellent appearance and good Comprehensive performance.

Embodiment 3

[0051] By weight percentage, 5% of 3000 mesh wollastonite, 1% of nano-montmorillonite, 4% of 5000 mesh kaolin, 0.5% of TAF, 0.5% of stearic acid, 0.1% of titanium aluminate composite coupling agent, 10760.1% , tris(2,4-di-tert-butylphenyl) phosphite 0.1%, maleic anhydride 0.2%, dicumyl peroxide 0.1%, carboimide 0.4%, add high-speed mixer at 50°C and mix for 30min and place B Put PBSA5%, PBS38%, polylactic acid 45% dry, add high-speed mixer at room temperature and mix for 8 minutes, place A weight loss meter, and enter the twin-screw extruder with B compound at the same time for melting and blending , Strand granulation, can be used to prepare various sheets and other various products. Dry the above resin and add it to a sheet extruder with a screw diameter of 130mm, and prepare a 0.3-1.2mm thick sheet at an extrusion temperature of 160-190°C and an extrusion speed of 20-35rpm, which has excellent appearance and Good overall performance.

[0052] The properties are shown in T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com