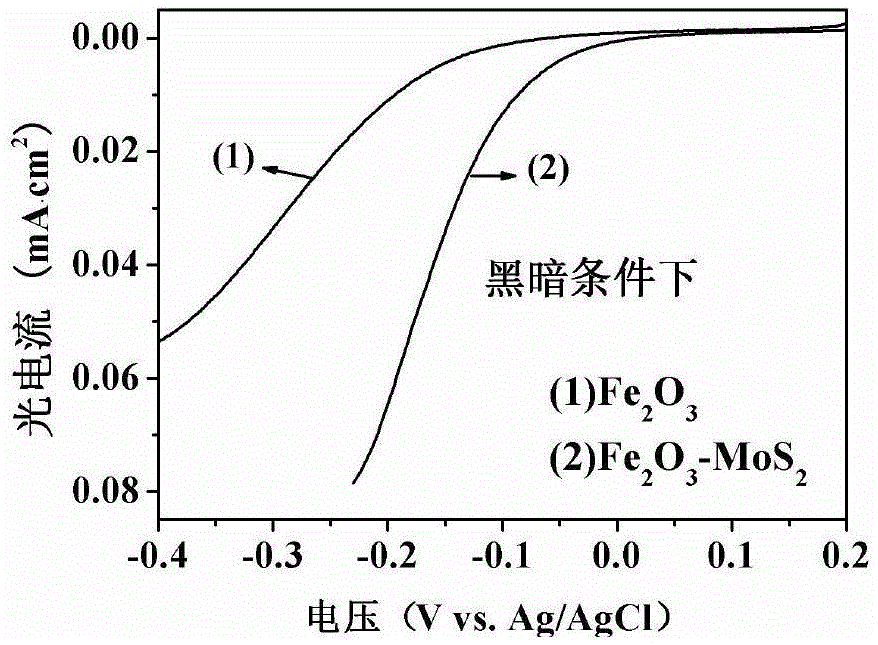

MoS2-doped iron oxide photocatalytic thin film and preparation method as well as application thereof to treatment of phenolic waste water

An iron oxide light and thin film technology, applied in catalyst activation/preparation, chemical instruments and methods, special compound water treatment, etc. problem, to achieve good photoelectric catalytic activity, high separation efficiency of photogenerated electrons and holes, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) with Fe 2+ precursor solution (Fe 2+ Derived from FeCl 2 ) as the electrolyte, the conductive substrate after cleaning and drying as the working electrode, the graphite electrode as the counter electrode, and the Ag / AgCl electrode as the reference electrode for electrodeposition.

[0053] The conductive substrate in this example is FTO glass (10 mm x 50 mm x 2 mm). Before preparing the film, it was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 10 min, and then taken out to dry.

[0054] The thickness of the film obtained by electrodeposition is controlled by electrodeposition process parameters. In this embodiment, the electrodeposition process parameters are as follows: electrodeposition temperature is 70° C., working voltage is 1.36 V, and deposition time is 5 minutes.

[0055] (2) Then put the conductive substrate deposited in step (1) into a muffle furnace and calcinate at 500°C for 2 hours to obtain Fe 2 o 3 Photocatalytic th...

Embodiment 2

[0068] The wastewater to be treated in this embodiment is phenol wastewater, wherein the initial concentration of phenol is 10 mg / L.

[0069] The MoS-based 2 The wastewater treatment method of the doped iron oxide photocatalytic film, the treatment process is as follows:

[0070] The pH of the solution before the reaction was measured, that is, the pH of the unadjusted phenol solution was about 6, and photocatalytic degradation was carried out. The photocatalytic anode used in photocatalytic treatment includes a conductive substrate and MoS coated on the surface of the conductive substrate. 2 Doped iron oxide photocatalytic film (made by embodiment 1), the cathode is a titanium sheet.

[0071] In the photocatalytic treatment in this embodiment, before the working voltage is applied to the photocatalytic electrode pair, the treated wastewater is also subjected to dark adsorption treatment, and the dark adsorption treatment time is 30 minutes.

[0072] During the photocatalyt...

Embodiment 3

[0078] Repeat the operating steps of Examples 1 and 2, the difference is to prepare MoS 2 In the process of doping the iron oxide photocatalytic film, the Fe in step (1) 2+ Fe in the precursor solution 2+ The source is ferrous acetate.

[0079] Fe prepared under the conditions of this example 2 o 3 -MoS 2 Thin film photoelectrochemical performance is worse than the Fe prepared under the conditions of Example 1 2 o 3 -MoS 2 film, under visible light, compared to Fe 2 o 3 Thin film (with comparative example 1), the Fe of the present embodiment 2 o 3 -MoS 2 The photocurrent (ie, current density) of the thin film is correspondingly increased by 23 times; under the ultraviolet-visible light, the photocurrent (ie, current density) is correspondingly increased by 20 times. The degradation rate of phenol under visible light conditions is 83.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com