Method for preparing hydroxyapatite-natural macromolecular nano compound with one-pot method

A technology of natural polymer and hydroxyapatite is applied in the field of preparing hydroxyapatite-natural polymer nanocomposite by one-pot method, which can solve the problems of simple operation of raw material powder, single product obtaining method, cumbersome and time-consuming, etc. To achieve the effect of simple method, saving water resources and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

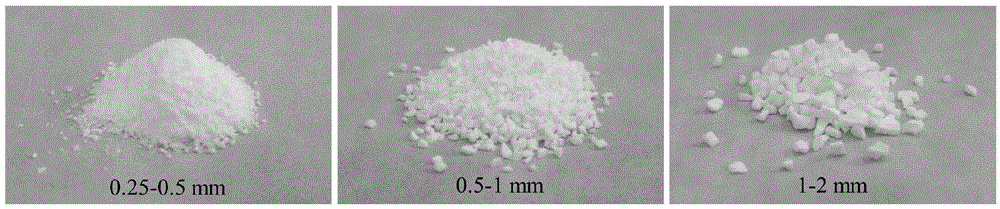

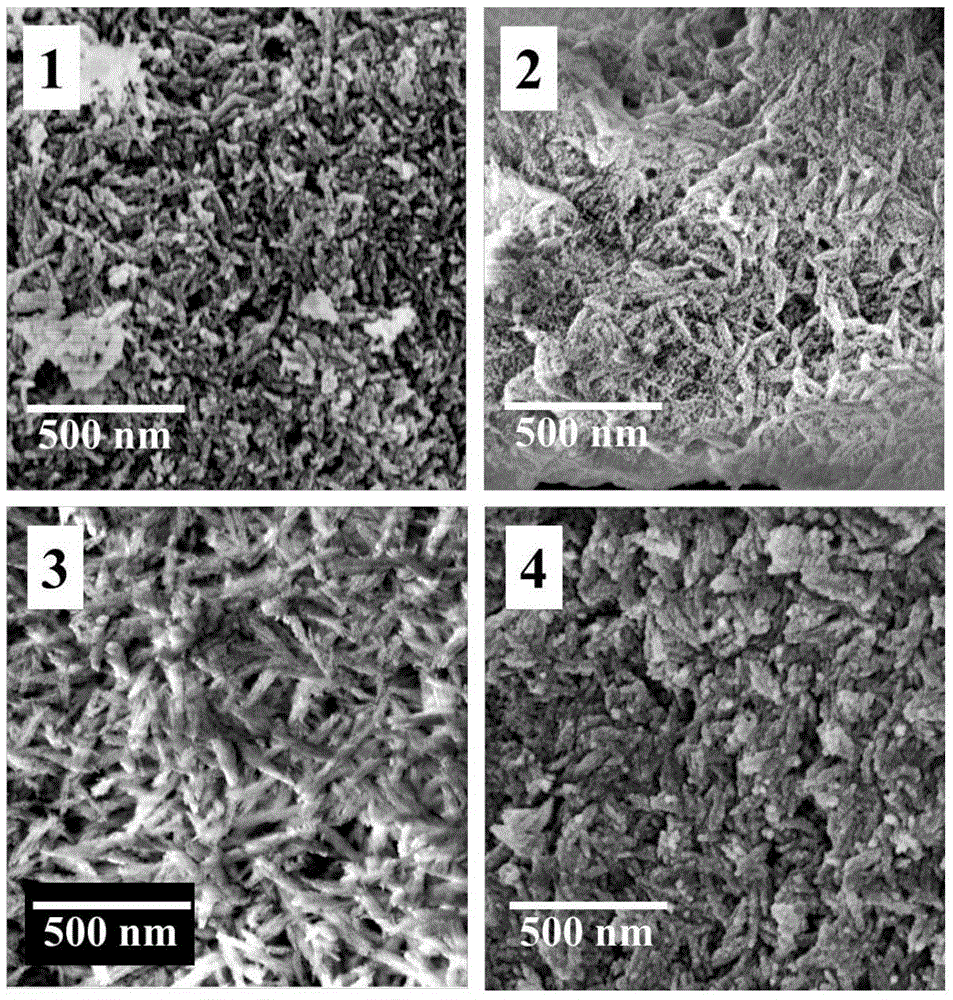

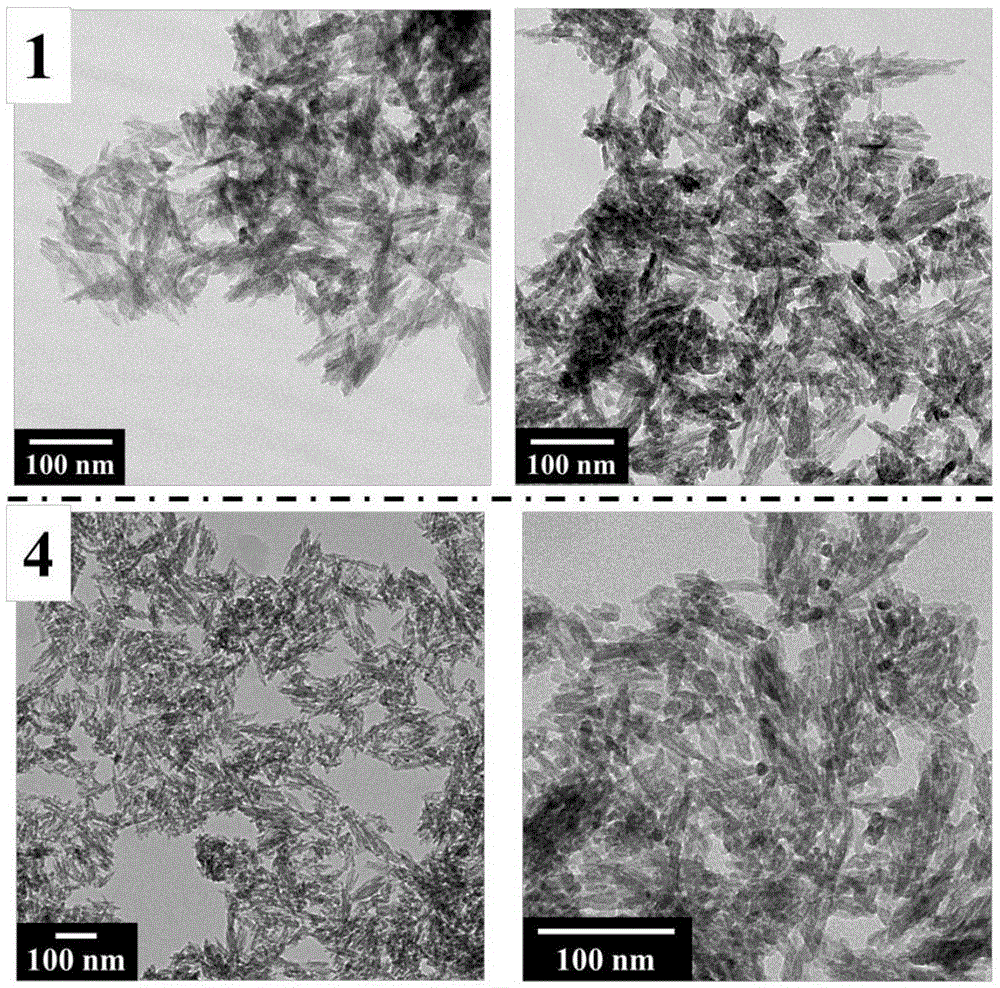

Examples

Embodiment 1

[0049] (1) Weigh 5.02 g of soluble silk fibroin, dissolve in 200 mL of deionized water in a constant temperature water bath at 40° C., and dissolve for 3 hours under stirring at a rotation speed of 1300 rpm to obtain a silk fibroin solution.

[0050](2) The silk fibroin solution is placed in a 40°C constant temperature water bath, and under stirring at a rotating speed of 1300rpm, 12.74g of potassium phosphate is added, and after dissolving, 23.61g of calcium nitrate tetrahydrate is added, and Ca / P= 5:3 (the ratio of the amount of substance), the ratio of the mass of the natural polymer to the mass sum of calcium ions and phosphate ions in the two precursor salts is 0.518. After 5 minutes, add 100mL of ammonia water (NH 3 The concentration is 25-28%), and the stirring speed is adjusted to 650rpm, stirring for 3h to make it fully react.

[0051] (3) After the reaction is completed, the stirring is stopped, and the reaction product is aged for 12 hours at a constant temperature ...

Embodiment 2

[0057] (1) Weigh 5.02 g of soluble silk fibroin, dissolve it in 200 mL of deionized water in a constant temperature water bath at 40° C., and dissolve it for 3 hours under stirring at a rotation speed of 1300 rpm to obtain a silk fibroin solution.

[0058] (2) Put the silk fibroin solution in a constant temperature water bath at 40°C, and add 12.74g of potassium phosphate under stirring at a rotating speed of 1300rpm. After dissolving, add 11.10g of anhydrous calcium chloride. At this time, Ca / P =5:3 (ratio of the amount of substance), the ratio of the quality of the natural polymer to the mass sum of calcium ions and phosphate ions in the two precursor salts is 0.518. After 5 minutes, add 100mL ammoniacal liquor (NH 3 The concentration is 25-28%), and the stirring speed is adjusted to 650rpm, stirring for 9h to make it fully react.

[0059] (3) After the reaction is completed, the stirring is stopped, and the reaction product is aged for 15.5 hours at a constant temperature o...

Embodiment 3

[0065] (1) Weigh 1.01 g of soluble silk fibroin, dissolve it in 40 mL of deionized water in a constant temperature water bath at 40° C., and dissolve it for 3 hours under stirring at a rotation speed of 1300 rpm to obtain a silk fibroin solution.

[0066] (2) The silk fibroin solution is placed in a 40°C constant temperature water bath, and under stirring at a rotating speed of 1300rpm, 1.44g of sodium dihydrogen phosphate is added, and after dissolving, 4.723g of calcium nitrate tetrahydrate is added. At this time, Ca / P=5:3 (ratio of the amount of substance), the ratio of the mass of the natural polymer to the mass sum of calcium ions and phosphate ions in the two precursor salts is 0.521. After 5 minutes, add 20mL of ammonia water (NH 3 The concentration is 25-28%), and the stirring speed is adjusted to 650rpm, stirring for 20h to fully react.

[0067] (3) After the reaction is completed, the stirring is stopped, and the reaction product is aged for 14 hours at a constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com