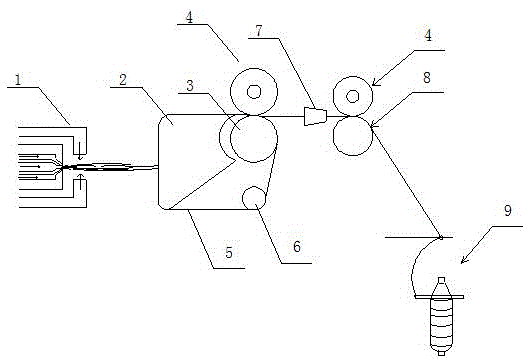

Novel micro-nano fiber yarn spinning device and technology

A technology of micro-nano fibers and yarns, which is applied to spinning machines, continuous winding spinning machines, melt spinning, etc., and can solve the problems of reduced output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

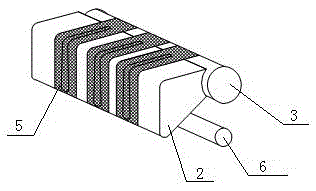

Method used

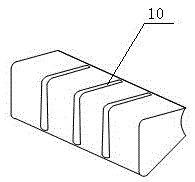

Image

Examples

Embodiment 1

[0039] A single-hole melt-blown testing machine is used, the width of the air groove is 0.65mm; the angle of the air groove is 30°; the diameter of the spinneret hole is 0.42mm, and the spinneret process is: the temperature of the polymer melt is 265°C, and the temperature of the hot air is 280°C , the air pressure is 0.4MPa, the receiving distance is 8cm, the melt flow rate of the PP polymer used is 1000g / 10min, and the average diameter of the spun fibers is between 0.6-0.8μm.

[0040] Spinning process parameters: the diameter of the first roller and the second roller are both 30mm, the speed of the first roller is 500cm / min, the speed of the second roller is 150cm / min, the length of the grid circle is 28.5cm, and the number of grid circle holes is 2400 hole / cm 2 , The upper width C of the suction port of the special-shaped pipe is 5mm, the lower width B is 10mm, the inclination angle A is 80°, and the negative pressure of the special-shaped exhaust pipe is 10Pa. For the twi...

Embodiment 2

[0042] A single-hole meltblown test machine is used, the air groove width is 0.65mm; the air groove angle is 30°; the spinneret hole diameter is 0.42mm. The spinning process is: the polymer melt temperature is 265°C; the air pressure is 0.35MPa; the receiving distance is 20cm, the hot air temperature is 200°C, the melt flow rate of the PP polymer used is 900g / 10min, and the average diameter of the spinning fiber is is 1.2 μm.

[0043]Spinning process parameters: the diameter of the first roller and the second roller are both 30mm, the speed of the first roller is 1000cm / min, the speed of the second roller is 350cm / min, the length of the grid circle is 28.5cm, and the number of grid circle holes is 400 hole / cm 2 , The upper width C of the special-shaped pipe suction port is 10mm, the lower width B is 20mm, the inclination angle A is 70°, and the negative pressure of the special-shaped exhaust pipe is 100Pa. For the twisting part, the ring is PG1-4254, the traveler is 68022#, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| perimeter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com