Preparation method for carbon-film-coated zinc oxide hollow sphere

A technology of zinc oxide and coating, which is applied in the field of preparation of zinc oxide hollow balls, to achieve the effects of increasing the contact area, making the production process environmentally friendly, and improving the charging and discharging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

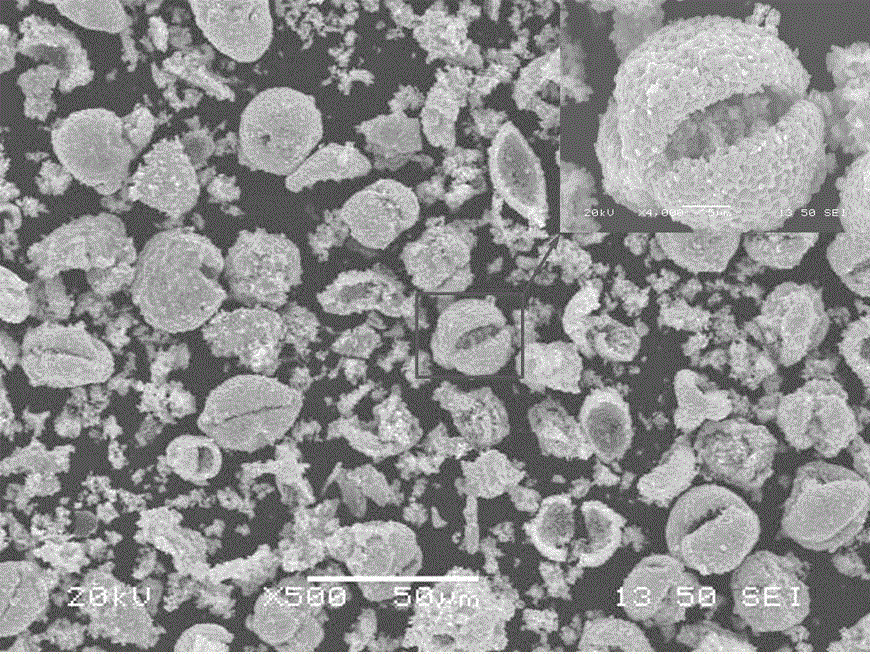

Image

Examples

Embodiment 1

[0025] Mix 50ml of ethanol solution of zinc acetate (purity: 99.5%) with a concentration of 0.10mol / l, and 0.0439g of rapeseed pollen (mass ratio to zinc acetate = 25:1) with a purity of 99%, and ultrasonically disperse for 30min; then The mixture was placed in a water bath at 80 °C and stirred magnetically. Take by weighing urea 0.6030g (OH - : Zn 2+ Molar ratio = 2:1) dissolved in 50ml ethanol solution. Add the urea solution drop by drop to the mixed solution of zinc acetate and rape pollen, the titration rate is 0.1ml / min, and continue to stir and age for 2h after the drop. The aged solution was centrifuged 5 times, and the precipitate was washed with ethanol after each centrifugation. The isolated precipitate was dried at 80 °C for 12 h. The dried white powder is placed in a high-temperature furnace and sintered in air at a sintering temperature of 400°C and kept at this temperature for 3 hours. The ZnO hollow spheres without the pollen template were obtained after th...

Embodiment 2

[0027] Mix 50ml of ethanol solution of zinc nitrate (purity: 99.5%) with a concentration of 0.50mol / l, and 0.1487g of camellia pollen (mass ratio to zinc acetate = 50:1) with a purity of 99%, and ultrasonically disperse for 20min; then The mixture was placed in a water bath at 80 °C and stirred magnetically. Weigh 1.5075g of urea (OH) with a purity of 99.5% - : Zn 2+ Molar ratio = 1:1) dissolved in 100ml ethanol solution. Add the urea solution drop by drop to the mixed solution of zinc nitrate and camellia pollen, the titration rate is 0.15ml / min, and continue to stir and age for 2h after the drop. The aged solution was centrifuged 5 times, and the precipitate was washed with ethanol after each centrifugation. The separated precipitate was dried at 100 °C for 8 h. The dried white powder is placed in a high-temperature furnace and sintered in air at a sintering temperature of 500°C and kept at this temperature for 4 hours. The ZnO hollow spheres without the pollen template...

Embodiment 3

[0029] Mix 50ml of ethanol solution of zinc nitrate (purity: 99.5%) with a concentration of 1.0mol / l, and 0.1487g of camellia pollen (mass ratio to zinc nitrate = 100:1) with a purity of 99%, and ultrasonically disperse for 10 minutes; then The mixture was placed in a water bath at 80 °C and stirred magnetically. Weighing urea 4.5223g (OH - : Zn 2+Molar ratio = 1.5:1) dissolved in 100ml ethanol solution. Add the urea solution drop by drop to the mixed solution of zinc nitrate and camellia pollen, the titration rate is 0.2ml / min, and continue stirring and aging for 1.5h after dropping. The aged solution was centrifuged 5 times, and the precipitate was washed with ethanol after each centrifugation. The separated precipitate was dried at 90 °C for 10 h. The dried white powder is placed in a high-temperature furnace and sintered in air at a sintering temperature of 600°C and kept at this temperature for 5 hours. The ZnO hollow spheres without the pollen template were obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com