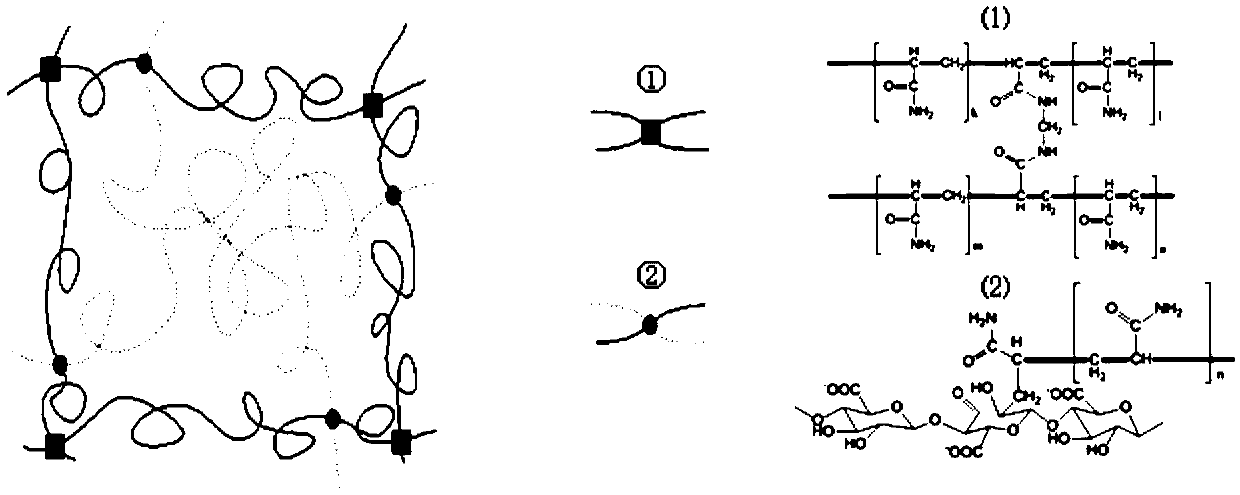

Sodium alginate-acrylamide composite aquagel, and preparation method and application thereof

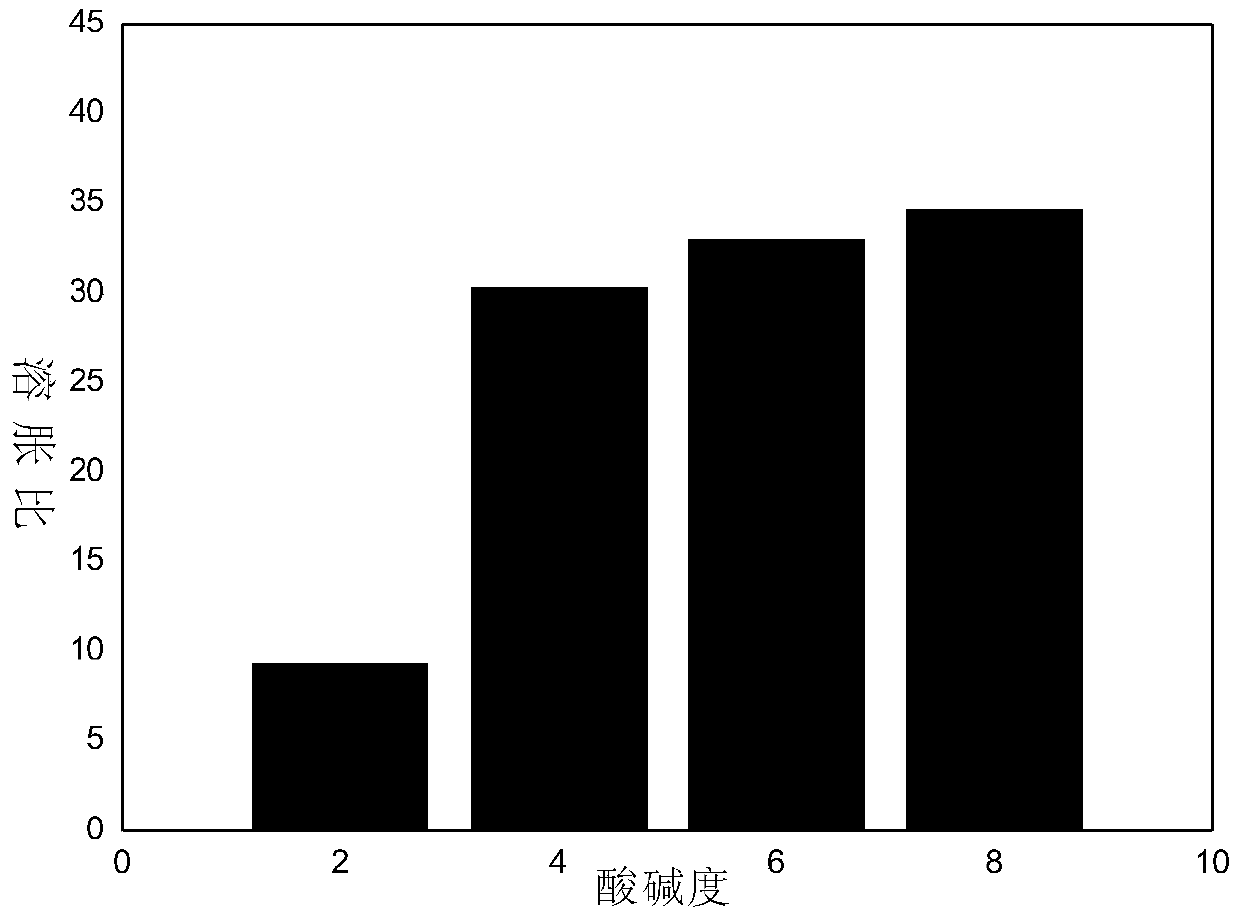

A composite hydrogel and acrylamide technology, which is applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as easy swelling, limit the application of sodium alginate, and poor mechanical properties, and achieve Low cost, good multivalent ion adsorption capacity and biocompatibility, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of sodium alginate-acrylamide composite hydrogel, its preparation method comprises the following steps:

[0035] Dissolve sodium alginate (SA) powder and acrylamide (AM) in ionized water at a mass ratio of 1:5 at room temperature to obtain a uniform mixed solution I. The total concentration of sodium alginate and acrylamide in mixed solution I is 11wt %; then add N,N'-diallyl tartaric acid diamide and sodium persulfate in turn, after dissolving, perform vacuum defoaming treatment (vacuumize to 0.02MPa, time is 2h), then add sodium bisulfite and mix evenly, The mass ratios of N,N'-diallyl tartaric acid diamide, sodium persulfate, sodium bisulfite and acrylamide monomer are 3.85:0.9:1.55:100 respectively, and then the resulting solution is transferred to a glass under nitrogen atmosphere In the mold, after sealing, heat-retain and react at 70° C. for 2.5 hours to form the sodium alginate-acrylamide composite hydrogel.

[0036] The formed sodium alginate-acrylamide...

Embodiment 2

[0039] A kind of sodium alginate-acrylamide composite hydrogel, its preparation method comprises the following steps:

[0040]Dissolve sodium alginate (SA) powder and acrylamide (AM) in ionized water at a mass ratio of 1:7 at room temperature to obtain a uniform mixed solution I, the total concentration of sodium alginate and acrylamide in mixed solution I is 13wt %; then add divinylbenzene and potassium persulfate in turn, after dissolving, carry out vacuum defoaming treatment (vacuumize to 0.015MPa, time is 1.3h), then add sodium sulfite and mix evenly, wherein divinylbenzene, potassium persulfate, The mass ratio of sodium sulfite to acrylamide monomer is 2.95:1.9:2.35:100 respectively, and then the obtained solution is transferred to a glass mold in a nitrogen atmosphere, sealed and kept at 60°C for 6 hours, and the alginic acid is obtained by molding Sodium-acrylamide composite hydrogel.

[0041] The formed sodium alginate-acrylamide composite hydrogel was taken out and c...

Embodiment 3

[0044] A kind of sodium alginate-acrylamide composite hydrogel, its preparation method comprises the following steps:

[0045] Dissolve sodium alginate (SA) powder and acrylamide (AM) in ionized water at a mass ratio of 1:9 at room temperature to obtain a uniform mixed solution I, the total concentration of sodium alginate and acrylamide in mixed solution I is 15wt %; then add polyoxyethylene glycol diacrylate and sodium persulfate in sequence, after dissolving, carry out vacuum defoaming treatment (vacuumize to 0.01MPa, time is 2.5h), then add sodium thiosulfate and mix evenly, among which polycondensate The mass ratios of ethylene glycol diacrylate, sodium persulfate, sodium thiosulfate and acrylamide monomer are 4.8:0.1:0.25:100 respectively, and then the resulting solution is transferred to a glass mold in an argon atmosphere, sealed and placed in The sodium alginate-acrylamide composite hydrogel was molded and reacted at 45° C. for 4 hours.

[0046] The formed sodium alg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com