A kind of preparation method of chitin liquefaction product/polyvinyl alcohol blend film

A liquefied product, polyvinyl alcohol technology, applied in the field of preparation of chitin liquefied product/polyvinyl alcohol blend film, can solve the problems of limited application range, poor heat resistance, no antibacterial properties, etc., to avoid stress defects, Better Performance, Enhanced Flexibility Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

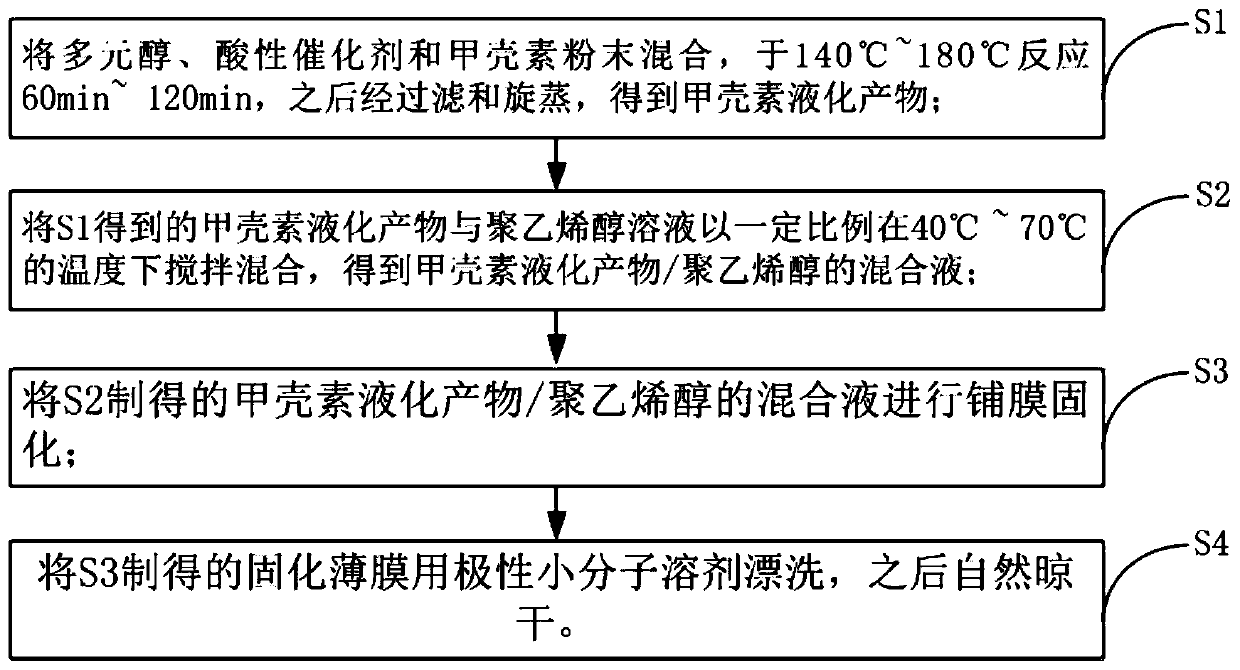

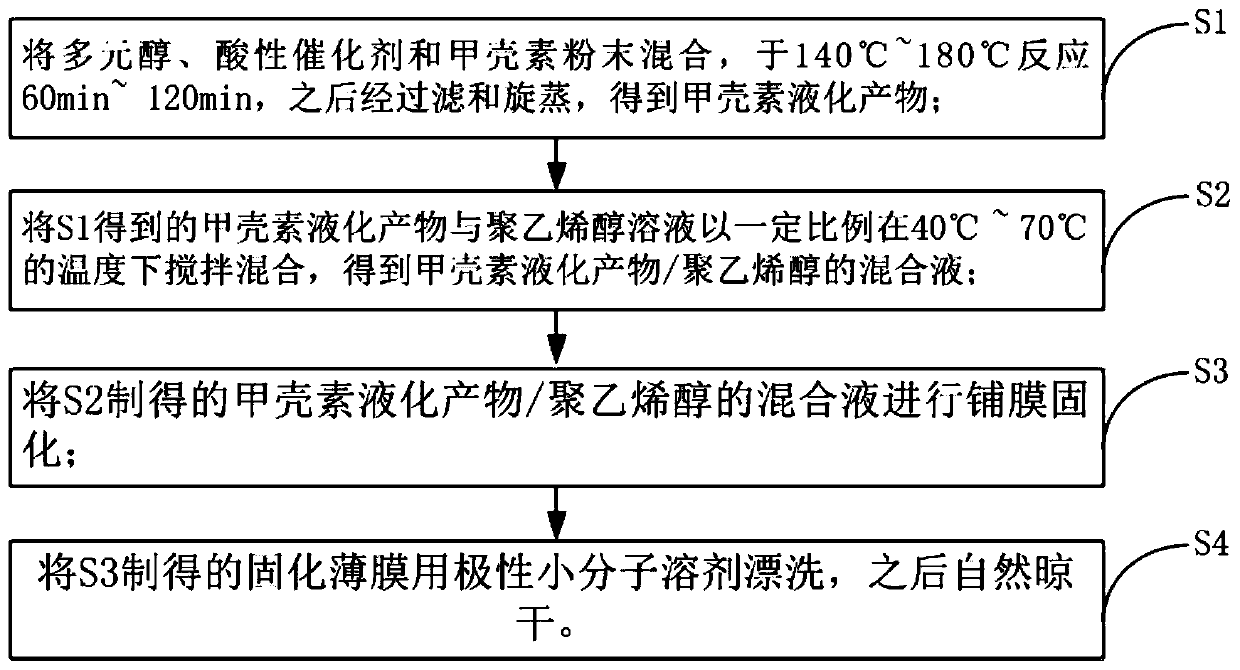

[0027] see figure 1 . The invention discloses a preparation method of a chitin liquefaction product / polyvinyl alcohol blend film, which comprises the following steps:

[0028] S1: Mix polyol, acidic catalyst and chitin powder, react at 140°C-180°C for 60min-120min, then filter and rotary steam to obtain chitin liquefaction product. Wherein, the consumption of polyhydric alcohol, acidic catalyst and chitin is calculated by mass parts: polyhydric alcohol: 50 parts-75 parts, acidic catalyst: 2 parts-6 parts, chitin: 10 parts; Polyhydric alcohol can be ethylene glycol, Or diethylene glycol, or glycerol, or one or more mixed solutions in polyethylene glycol, and the acidic catalyst can be formic acid, or acetic acid, or oxalic acid, or hydrochloric acid, or the concentrated sulfuric acid. The liquefaction step is a chemical reaction of the polyol under the action of an acidic catalyst, which breaks the macromolecular chitin solid powder into small molecules and transforms it into...

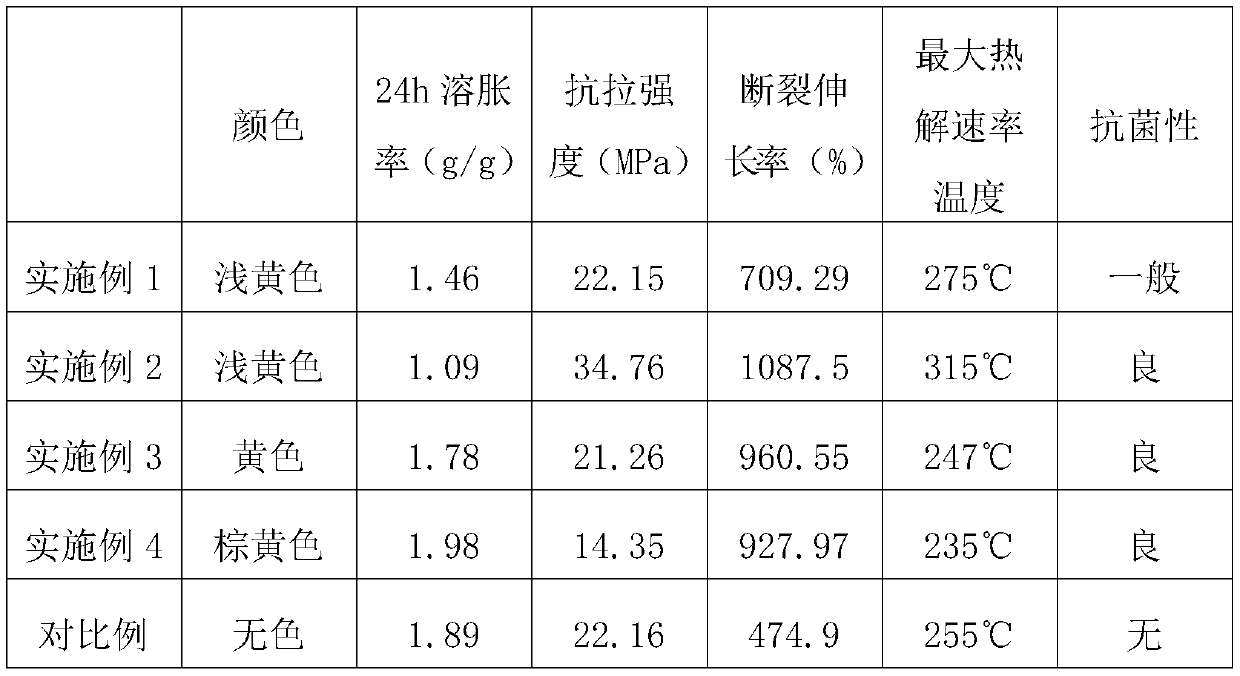

Embodiment 1

[0037] The mixed solution of 7g polyethylene glycol and glycerol (mass ratio of polyethylene glycol and glycerol is 4:1, wherein the molecular weight of polyethylene glycol is 400) and 0.5g vitriol oil are mixed homogeneously in there-necked flask, Add 1g of chitin, stir, and react at 160°C for 90 minutes to obtain 8g of liquefied product; 64g of polyvinyl alcohol and 1600g of deionized water are heated at 90°C for 2 hours, then filtered, and left to defoam to obtain a polyvinyl alcohol solution; Mix 8g of liquefied product with 1664g of polyvinyl alcohol solution at 65°C, and continue to stir for 3h; pour the mixed solution on a glass plate model, spread the film by casting method, and cure it at room temperature for 24h, and the cured blended film After rinsing in ethanol, put it out and let it dry naturally.

[0038] The appearance of the chitin liquefied product / polyvinyl alcohol blend film obtained is a light yellow film, and its technical indicators are as follows:

[0...

Embodiment 2

[0045] The mixed solution of 7g polyethylene glycol and glycerol (mass ratio of polyethylene glycol and glycerol is 4:1, wherein the molecular weight of polyethylene glycol is 400) and 0.5g, 98% concentrated sulfuric acid in a three-necked flask Mix evenly, add 1g of chitin, stir, place at 160°C for 90min to obtain 8g of liquefied product; change the quality of polyvinyl alcohol, take 32g of polyvinyl alcohol and 800g of deionized water, heat at 90°C for 2h, and then filter , standing for defoaming to obtain polyvinyl alcohol solution; mix 8g of liquefied product with 832g of polyvinyl alcohol solution at 65°C, and continue to stir for 3h; After being cured for 24 hours, the cured blended film was rinsed in ethanol and taken out to dry naturally.

[0046] The appearance of the chitin liquefied product / polyvinyl alcohol blend film obtained is a light yellow film, and its technical indicators are as follows:

[0047] 24h swelling rate: 1.09g / g

[0048] Tensile strength: 34.76M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com