Glass-curtain-wall installing structure and glass-curtain-wall installing method

A glass curtain wall and installation structure technology, applied to walls, building components, building structures, etc., can solve problems such as safety hazards, weak glass installation, glass stress defects, etc., and achieve strong ozone resistance and corrosion resistance, installation The structure is stable and reliable, and the effect of avoiding stress defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

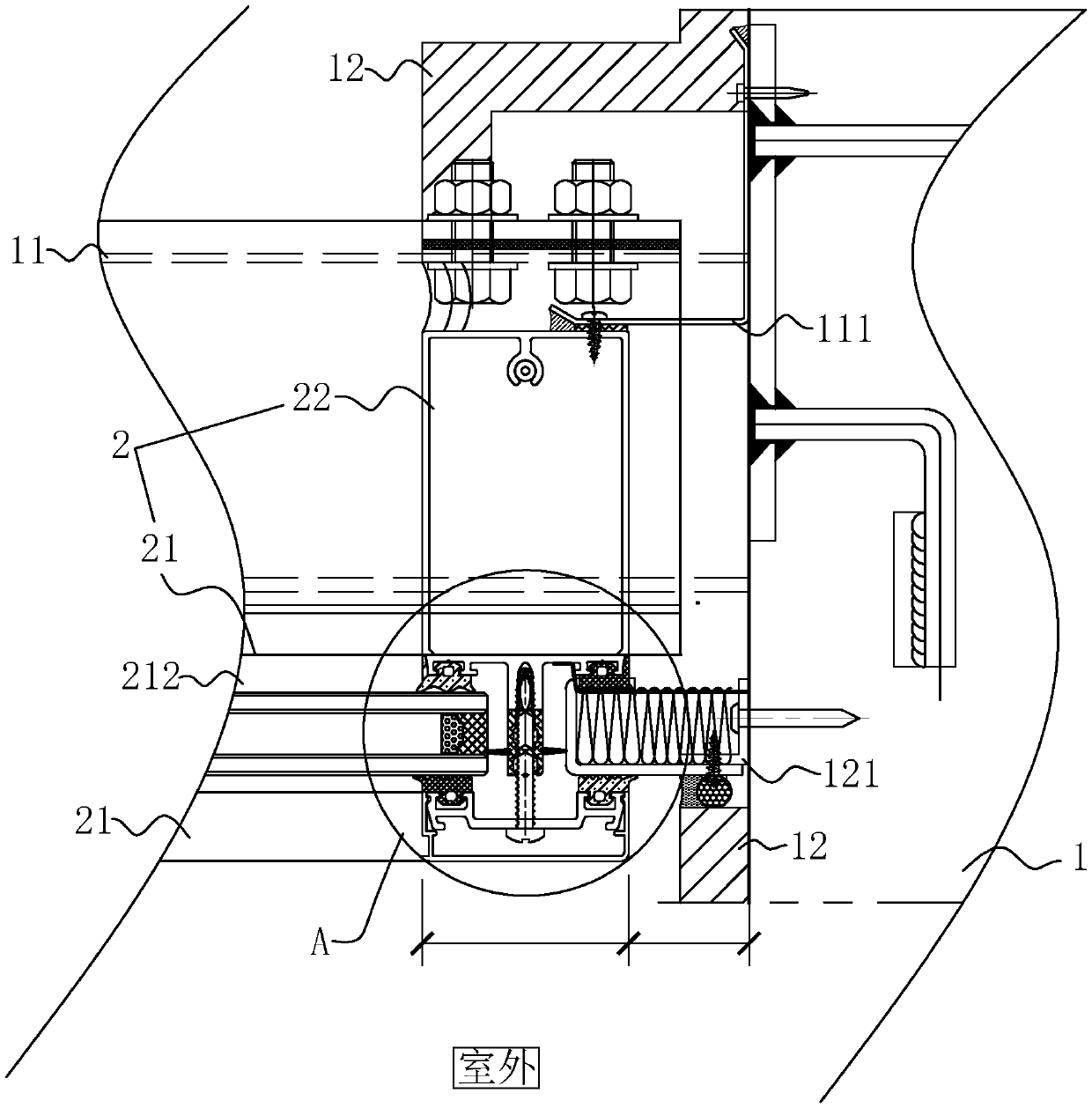

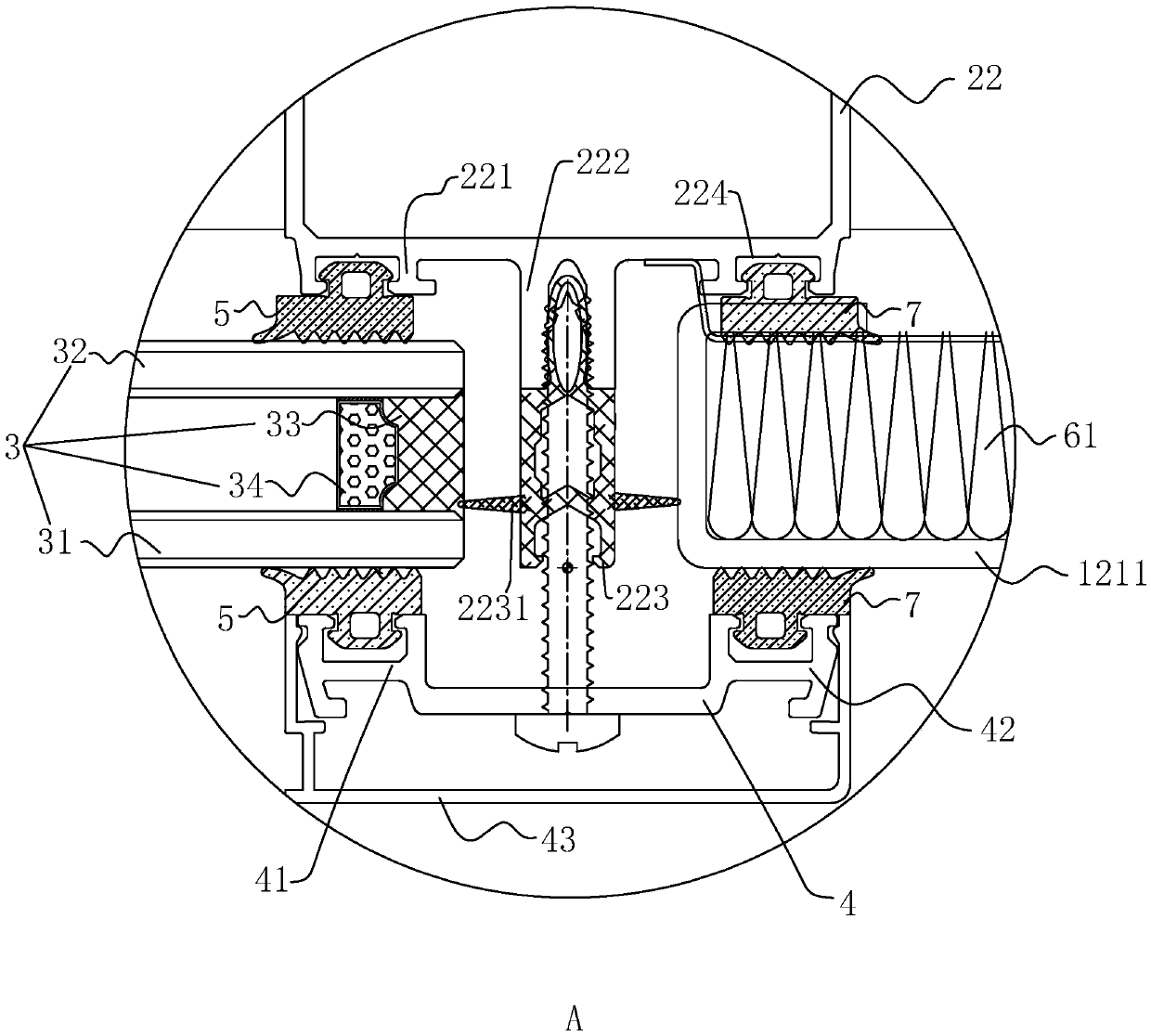

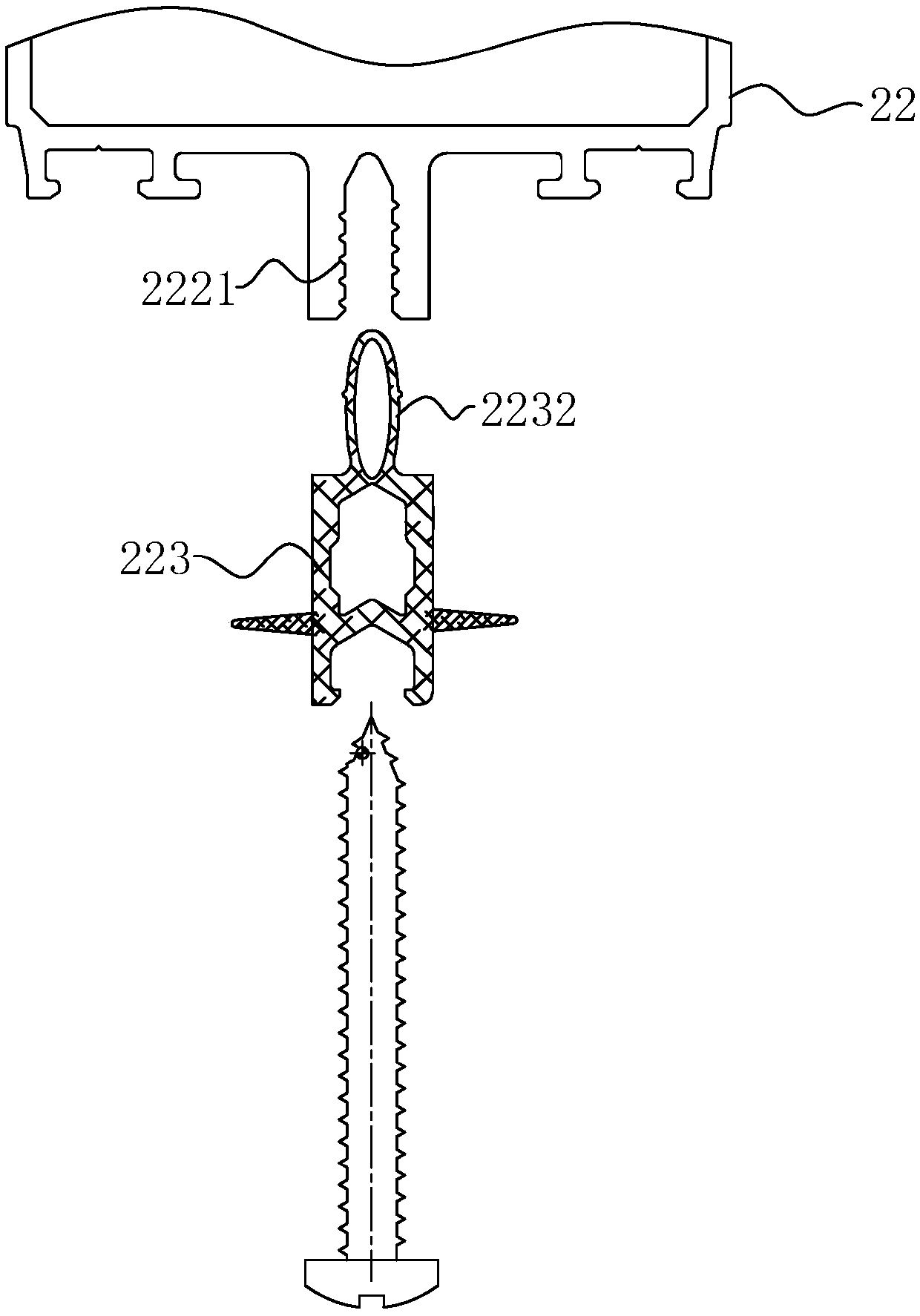

[0041] refer to figure 1 and figure 2, is an installation structure for a glass curtain wall disclosed in the present invention, including a wall 1 and a frame 2, the frame 2 is fixedly installed on the wall 1, and a plate-type embedded part is arranged in the wall 1 (the plate-type embedded part is arranged on the wall 1 inside, not marked in the figure), the frame 2 is provided with a glass 3, the frame 2 includes a column 21 and a horizontal frame 22, the column 21 and the horizontal frame 22 are provided with at least one place, and the column 21 is provided with a first installation groove 211 (No. One installation groove 211 is covered by the horizontal frame 22, so it is not marked in the figure) and the second installation groove 212, the first installation groove 211 is arranged horizontally, the second installation groove 212 is vertically arranged, the horizontal frame 22 is fixedly installed and the first installation In the groove 211, the glass 3 is arranged in...

Embodiment 2

[0052] An installation method of a glass curtain wall, based on the installation structure of a glass curtain wall described in Embodiment 1, the installation method includes:

[0053] Step 1: install the steel sleeve core 11 through threads on the wall body 1, the column 21 is sleeved on the steel sleeve core 11, and fixed on the steel sleeve core 11 by bolts;

[0054] Step 2: Fix one end of the first steel plate 111 between the wall body 1 and the steel sleeve core 11, then install the cross frame 22 on the first groove, and install bolts from the other end of the first steel plate 111, the bolts passing through the side wall of the first groove and being installed into the beam;

[0055] Step 3: Install the outdoor painting 12 on the body of wall 1, install the first steel plate 111 and the second steel plate 121 on the outdoor painting 12, the outdoor painting 12, the first steel plate 111 and the second steel plate 121 enclose the accommodation chamber 6, and An insulati...

Embodiment 3

[0061] refer to Figure 4 and Figure 5 , a glass curtain wall installation structure, this embodiment is used for the installation between glass 3 and glass 3, and the difference from Embodiment 1 is: a glass 3 is arranged between two second rubber strips 7, and the first Glass 3 is installed between the rubber strips 5 and between the second rubber strips 7, so that the installation structure can be placed between the glass 3 and the glass 3, installed in the middle of the glass 3 curtain wall, and used as a glass 3 curtain wall. The partition bears the gravity of the glass 3, and the fins 2231 are arranged at four places to strengthen and stabilize the installation structure of the glass 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com