Preparation method of high-performance co-doped lithium titanate electrode material

An electrode material, heterolithium titanate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of single ion doping, nanotechnology use restrictions, etc., and achieve the effect of high current charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

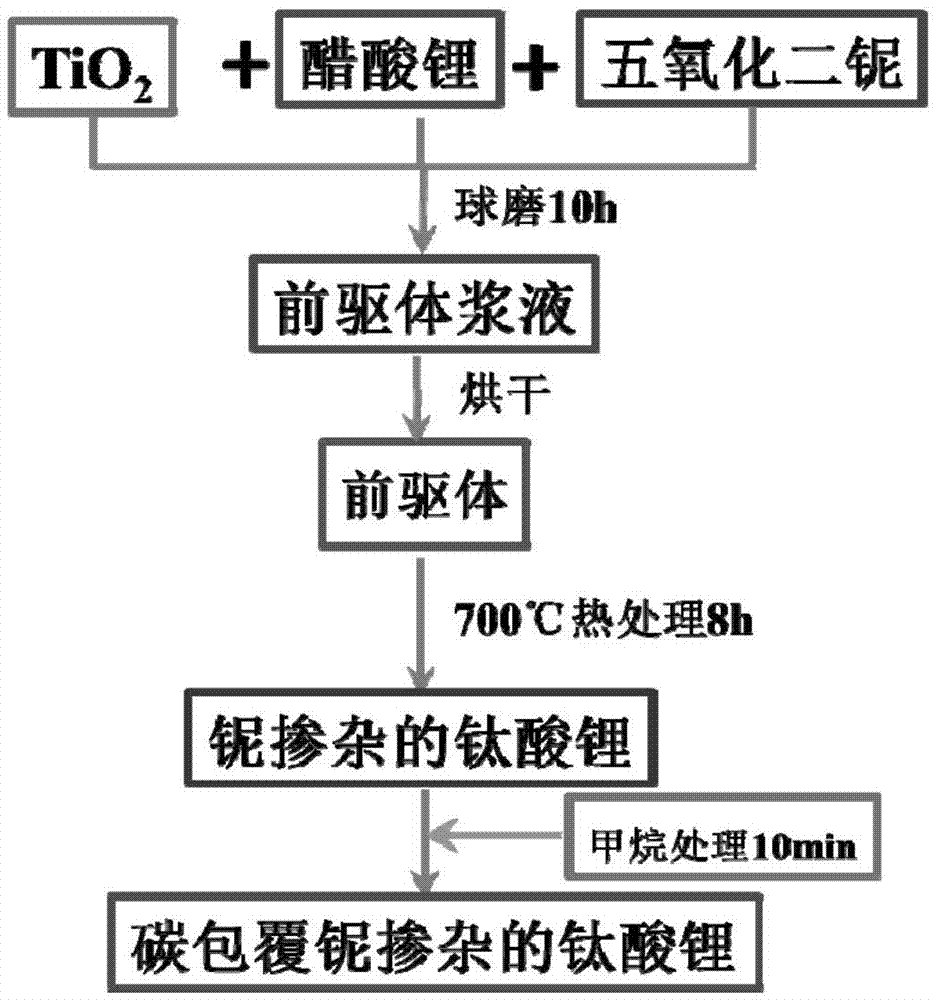

[0030] A method for preparing a high-performance co-doped lithium titanate electrode material, specifically comprising the following steps:

[0031] 19.95g of titanium dioxide, 13.20g of lithium acetate, and 0.033g of niobium pentoxide were weighed in acetone, and then mixed in a ball mill at 300r / min to obtain a precursor slurry. The obtained precursor slurry was placed in a blast drying oven at 60° C. to dry to obtain a doped precursor. The obtained doped precursor was placed in a crucible and then placed in a muffle furnace for treatment at 700°C for 8 hours, and then cooled to room temperature to obtain niobium-doped lithium titanate. Then the obtained niobium-doped lithium titanate is placed in a tube furnace, under a nitrogen atmosphere, the temperature is raised to 600°C at 2°C / min and converted into methane, kept for 10min, and then cooled to room temperature under a nitrogen atmosphere. A carbon-coated niobium-doped lithium titanate electrode material is obtained. f...

Embodiment 2

[0033] A method for preparing a high-performance co-doped lithium titanate electrode material, specifically comprising the following steps:

[0034] Weigh 3.97g of titanium dioxide, 1.55g of lithium carbonate, and 0.055g of tantalum pentoxide in absolute ethanol, and mix in a ball mill at 400r / min to obtain a precursor slurry. The resulting precursor slurry was placed in a blast oven at 80°C to dry to obtain a doped precursor. The obtained doped precursor was placed in a crucible and placed in a muffle furnace for treatment at 850°C for 9 hours, and then cooled to room temperature to obtain internal tantalum-doped lithium titanate. The obtained tantalum-doped lithium titanate is then placed in a tube furnace, and under an argon atmosphere, the temperature is raised to 700°C at 5°C / min and converted into ammonia, kept for 30min, and then cooled to 700°C under an argon atmosphere At room temperature, a titanium nitride-coated tantalum-doped lithium titanate electrode material i...

Embodiment 3

[0036] A method for preparing a high-performance co-doped lithium titanate electrode material, specifically comprising the following steps:

[0037] 19.95 g of titanium dioxide, 9.02 g of lithium hydroxide monohydrate, and 0.036 g of molybdenum oxide were weighed in methanol at a molar ratio of 4.3:5, and mixed in a ball mill at 500 r / min to obtain a precursor slurry. The obtained precursor slurry was placed in a blast drying oven at 100° C. to dry to obtain a doped precursor. The obtained doped precursor was then placed in a crucible and placed in a muffle furnace for treatment at 900°C for 10 hours, and then cooled to room temperature to obtain molybdenum-doped lithium titanate. Then place the prepared molybdenum-doped lithium titanate in a tube furnace, heat up at 10°C / min to 900°C in a helium atmosphere, convert it into ethane, keep it warm for 60min, and then cool it down to room temperature in a helium atmosphere , to obtain a carbon-coated molybdenum-doped lithium tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com