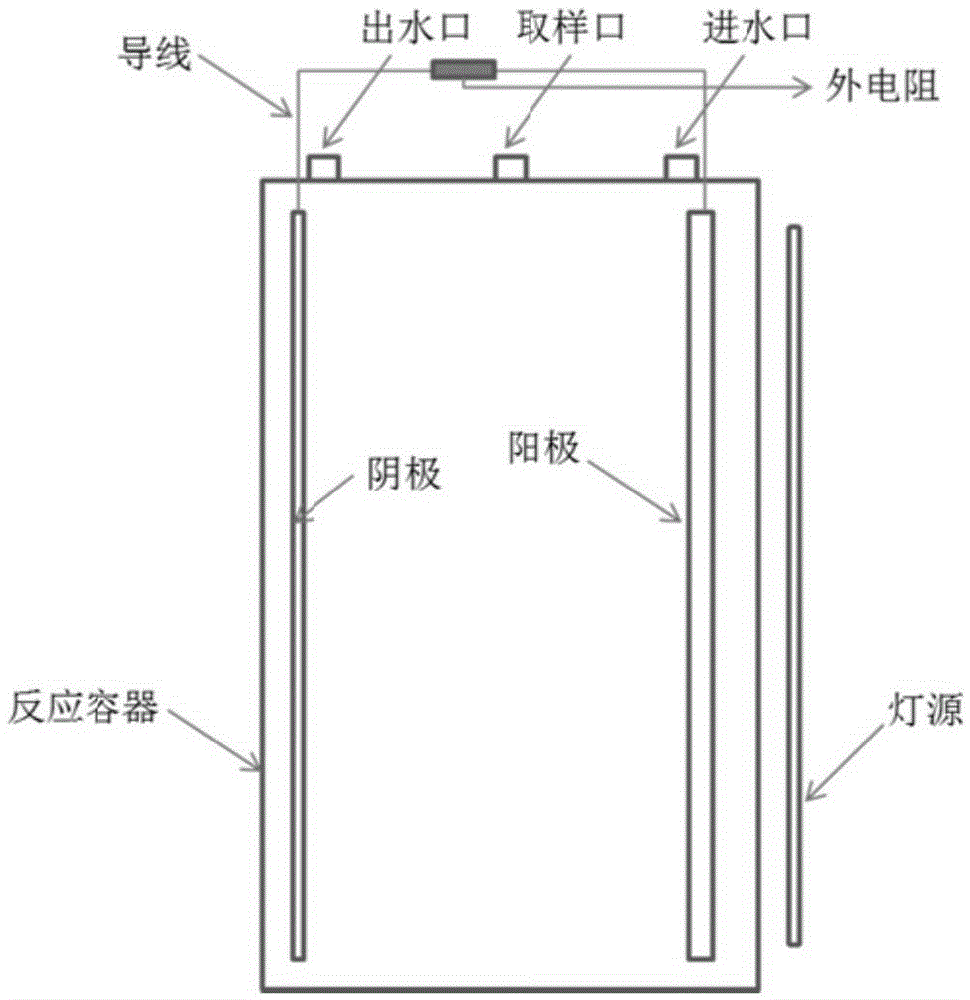

Microbial fuel cell electrode having photocatalytic synergistic effect as well as preparation method and application of electrode

A fuel cell electrode, synergistic effect technology, applied in biochemical fuel cells, battery electrodes, chemical instruments and methods, etc., can solve the problem of limited utilization of organic matter, and achieve widening the scope of substrate utilization, improving photocatalytic efficiency, and reducing the use of Effects of Conditional Restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

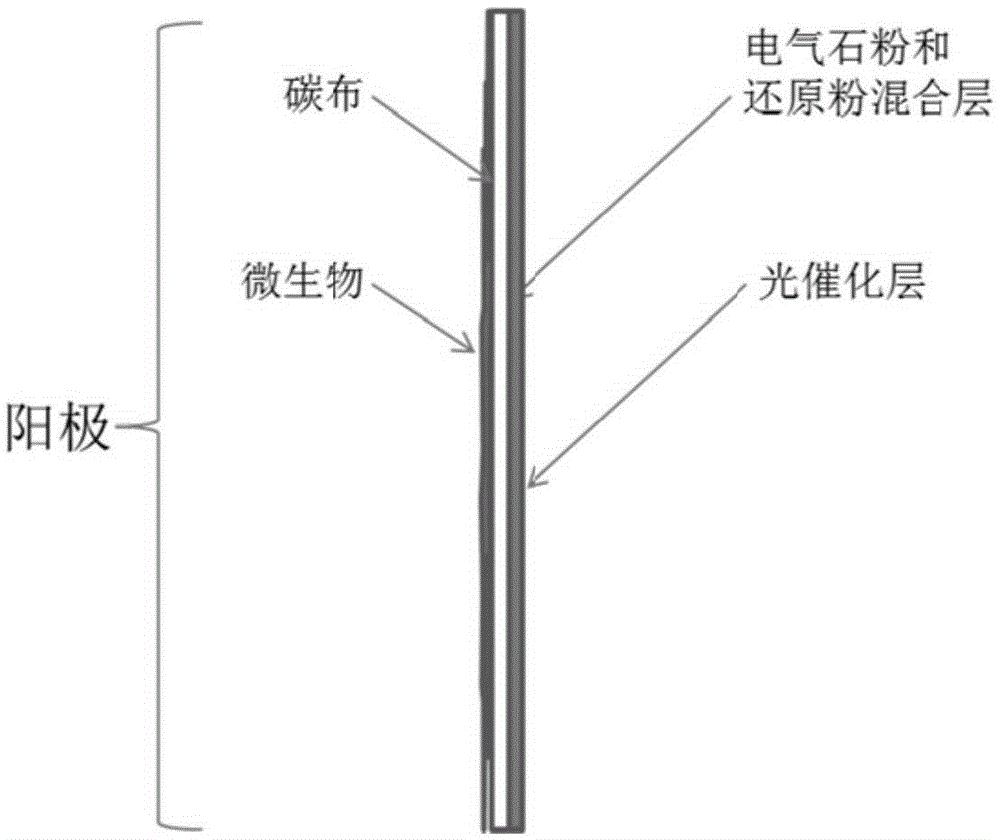

Embodiment 1

[0021] (1) Mix 0.25g tourmaline powder (8000 mesh), 0.06g iron powder (8000 mesh) and 0.06g epoxy resin powder, and spray the mixed powder onto a circular carbon cloth with a diameter of 5cm by electrostatic spraying.

[0022] (2) Place the sprayed carbon cloth in a resistance furnace at 200°C for 1 hour to obtain a carbon cloth loaded with mixed powder.

[0023] (3) Using isopropyl titanate as the titanium source, take 5 mL of isopropyl titanate and add it dropwise to 8 mL of absolute ethanol under the action of a magnetic stirrer to obtain solution A.

[0024] (4) Take 8 mL of absolute ethanol, add 1.5 mL of deionized water and 1.8 mL of glacial acetic acid one by one, then add bismuth nitrate and urea with a molar ratio of 0.01 to isopropyl titanate, and mix under the action of a magnetic stirrer Uniform solution B was obtained.

[0025] (5) Under the action of a magnetic stirrer, add solution B dropwise to solution A at a rate of 0.5 drops / s, continue stirring for 50 minu...

Embodiment 2

[0031] (1) Mix 0.25g tourmaline powder (8000 mesh), 0.06g iron powder (8000 mesh) and 0.06g epoxy resin powder, and spray the mixed powder onto a circular carbon cloth with a diameter of 5cm by electrostatic spraying.

[0032] (2) Place the sprayed carbon cloth in a resistance furnace at 200°C for 1 hour to obtain a carbon cloth loaded with mixed powder.

[0033](3) Using titanium isopropoxide as the titanium source, take 5 mL of titanium isopropoxide and add it dropwise to 10 mL of absolute ethanol under the action of a magnetic stirrer to obtain solution A.

[0034] (4) Take 10 mL of absolute ethanol, add 1.5 mL of deionized water and 1.8 mL of glacial acetic acid one by one, then add bismuth nitrate and urea with a molar ratio of 0.01 to titanium isopropoxide, and mix evenly under the action of a magnetic stirrer Solution B is obtained.

[0035] (5) Under the action of a magnetic stirrer, add solution B dropwise to solution A at a rate of 2 drops / s, continue stirring for 5...

Embodiment 3

[0041] (1) Mix 0.25g tourmaline powder (8000 mesh), 0.06g iron powder (8000 mesh) and 0.06g epoxy resin powder, and spray the mixed powder onto a circular carbon cloth with a diameter of 5cm by electrostatic spraying.

[0042] (2) Place the sprayed carbon cloth in a resistance furnace at 200°C for 1 hour to obtain a carbon cloth loaded with mixed powder.

[0043] (3) Arrange the carbon containing mixed powder in the magnetron sputtering chamber, and adjust the total pressure of the oxygen-argon mixture to 1pa, where O 2 The partial pressure accounts for 8% of the total air pressure. Immobilized pure TiO 2 The sputtering power of the target is 98kw / m 2 , fixed non-metallic doped TiO 2 The sputtering power of the target is 6.2kw / m 2 , fixed metal-doped TiO 2 The sputtering power of the target is 7.3kw / m 2 , deposited at room temperature for 25min to obtain co-doped TiO 2 .

[0044] (4) After the carbon cloth in (3) was annealed for 2 h at an annealing temperature of 490 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com