A microbial fuel cell coupled electrode biofilm phosphorus and nitrogen removal system and its application

A biofilm system and fuel cell technology, applied in biological water/sewage treatment, water pollutants, water/sludge/sewage treatment, etc., can solve the problem of low phosphorus removal efficiency, low power generation power of microbial fuel cells, and general removal efficiency. and other problems, to achieve the effect of simple process flow, small footprint, and improved power production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

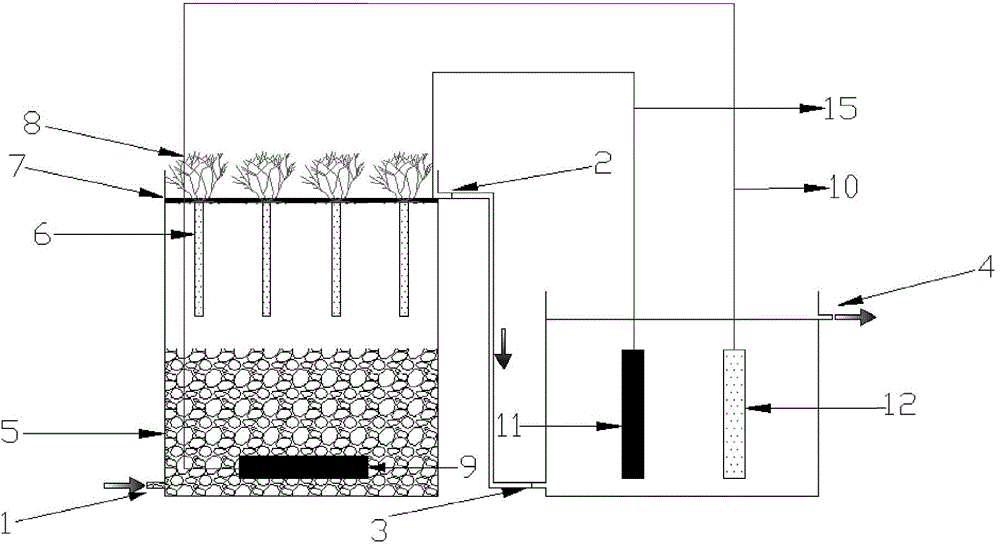

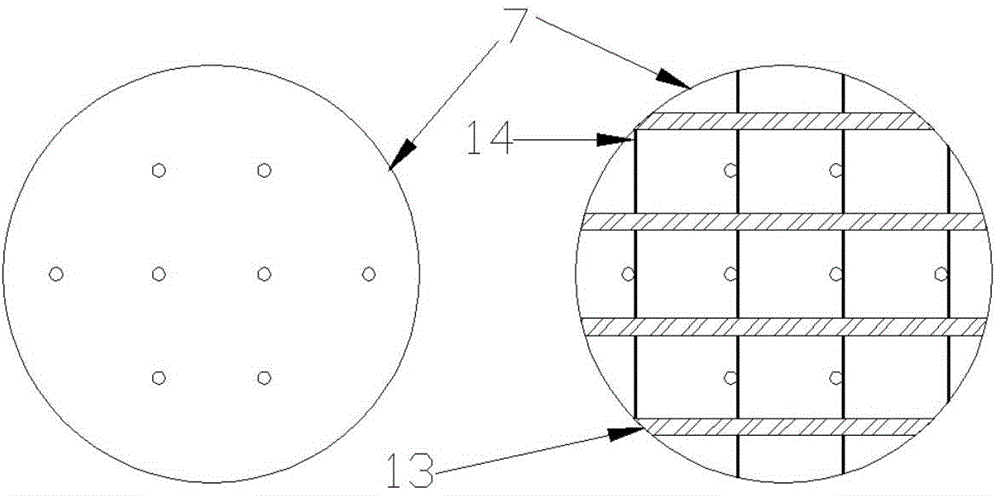

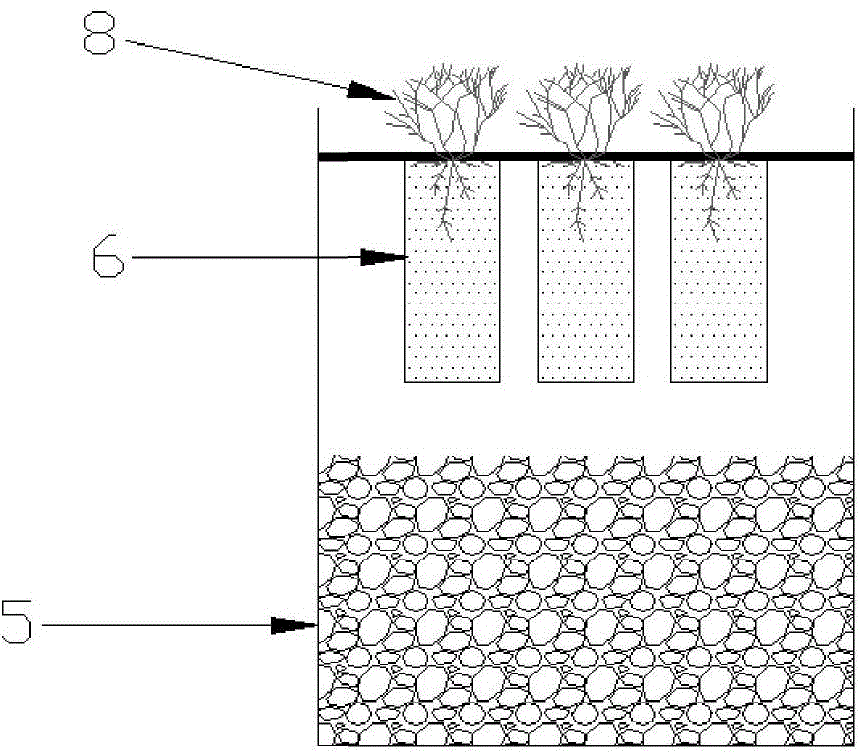

[0027] Such as figure 1 As shown, an ecological microbial fuel cell coupled electrode biofilm system that strengthens phosphorus and nitrogen removal is composed of an E-MFC subsystem and a BER subsystem, and the E-MFC subsystem includes an E-MFC reaction tank, E-MFC water inlet 1 on the bottom side of the E-MFC reaction tank, E-MFC water outlet 2 on the top side of the E-MFC reaction tank, non-conductive substrate laid on the bottom of the E-MFC reaction tank 5. Place the E-MFC anode electrode 9 in the non-conductive matrix 5, the E-MFC cathode electrode 7 positioned at the top of the E-MFC reaction tank, the plant 8 planted on the surface of the E-MFC cathode electrode 7, and the BER subunits The system includes a BER reaction tank, a BER water inlet 3 located on the bottom side of the BER reaction tank, a BER water outlet 4 located on the top side of the BER reaction tank, a BER anode electrode 11 and a BER cathode electrode 12 located in the BER reaction tank , the E-MFC ...

Embodiment 2

[0030] Basically the same as in Example 1, the difference is that the liquid level of the BER reaction tank is 10 cm lower than that of the E-MFC reaction tank. The non-conductive matrix 5 is shale.

Embodiment 3

[0032] Basically the same as in Example 1, the difference is that the liquid level of the BER reaction tank is 15 cm lower than that of the E-MFC reaction tank. The non-conductive matrix 5 is a mixture of shale and gravel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com