Long-cycle and high-safety power lithium ion battery positive electrode material and preparation method thereof

A technology of lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

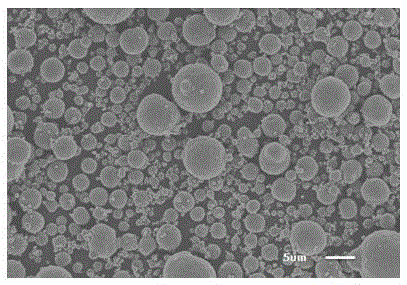

[0041] The nickel sulfate, cobalt sulfate, manganese sulfate, and magnesium sulfate with a molar ratio of Ni:Co:Mn:Mg of 4.97:2:3:0.03 are formulated into a mixed solution of 1.2m with a total concentration of 2mol / L 3 , And add polyacrylamide to the mixture to make the concentration 0.2mol / L. Add the mixture and 4mol / L NaOH solution dropwise into the reactor at the same time. The speed of the reactor is 500rpm, the temperature is 50℃, and the pH It is 11.5. After the addition is complete, continue stirring for 1h, add 4.8L Y2(SO4)3 solution with a concentration of 0.25mol / L dropwise, continue to stir for 10min after the addition, and then add NaOH with a concentration of 0.5mol / L dropwise The solution, until the pH is 11.8, stop dripping, continue to stir for 30 minutes, then filter and wash 3 times, take the upper filter cake, add deionized water to filter cake weight ratio of 1:1 and add to the stirred tank to disperse the filter cake to obtain The dispersion of the filter ca...

Embodiment 2

[0046] The Ni:Co:Mn:Al molar ratio is 7:1.5:1.45:0.05 of nickel sulfate, cobalt sulfate, manganese sulfate, and aluminum sulfate into a mixed solution 1.2m with a total concentration of 2mol / L 3 , And add carboxymethyl cellulose to the mixture to make the concentration 0.3mol / L. Add the mixture and 4mol / L NaOH solution dropwise to the reactor at the same time. The speed of the reactor is 500rpm and the temperature is 50℃. , PH is 11.5, after the addition is complete, continue stirring for 1h, add 4.5L of 0.3mol / L zirconyl nitrate solution dropwise, after the addition, continue to stir for 10min, and then add dropwise NaOH with a concentration of 0.5mol / L The solution, until the pH is 11.9, stop dripping, continue to stir for 30 minutes, then filter and wash 3 times, take the upper filter cake, add deionized water to filter cake weight ratio of 2.5:1 and add to the stirred tank to disperse the filter cake to obtain The dispersion of the filter cake is then spray-dried to obtain s...

Embodiment 3

[0051] Ni:Co:Mn:Ti molar ratio of 8:1:0.92:0.08 nickel nitrate, cobalt nitrate, manganese nitrate, titanium tetrachloride is prepared into a mixed solution 1.5m with a total concentration of 2.5mol / L 3 , And add polyethylene glycol to the mixture to make the concentration 0.3mol / L, and add the mixture and the KOH solution with a concentration of 6mol / L into the reactor at the same time. The speed of the reactor is 600rpm and the temperature is 65℃. The pH is 11.3, after the dripping is completed, continue stirring for 1h, add 5L Ce(NO3)3·6H2O solution with a concentration of 0.28mol / L dropwise, continue to stir for 10min after dripping, and then add the concentration to 0.6mol / L The NaOH solution was added until the pH was 12.1, and then the dripping was stopped. Continue stirring for 30 minutes, then filter and wash 3 times, take the upper filter cake, and add deionized water to filter cake with a weight ratio of 3:1 and add it to the stirred tank to disperse the filter cake. ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com