Strippable radiation-resistant and anti-corrosion coating for nuclear use and preparation method thereof

An anti-corrosion coating and radiation-resistant technology, applied in the field of radiation-resistant materials, can solve problems such as difficulty in complete cleaning, contamination by radioactive substances, difficult cleaning and decontamination of anti-radiation plastic construction technology, etc., to achieve easy peeling and replacement, and improve coating toughness , Easy to decontaminate and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Synthesis of modified epoxy resin: first mix 34.0kg E-12, 20.0kg E-06, 0.6kg dimethylethanolamine and 28.0kg mixed solvent (12.0kg xylene, 11.0kg butyl acetate and 5.0kg Methyl isobutyl ketone) was added, after stirring evenly, 17.4kg of linoleic acid was added and the temperature was raised to 145°C, the temperature was kept until the acid value was ≤2.16mg KOH / g, the temperature was lowered to 28°C, and the material was discharged to obtain the modified epoxy resin .

[0058] (2) Preparation of peelable primer first component

[0059] , first dispersant (2.0kg EFKA-4340, 2.0kg BYK-110), leveling agent (0.2kg BYK-388, 0.4kg BYK-320), defoamer (0.4kg BYK-051, 0.3kg BYK-A 530) and 4.4kg BYK-394 were added to 20.0kg of mixed solvent (5.0kg of propylene glycol methyl ether acetate, 10.0kg of butyl acetate and 5.0kg of butanone), and after stirring well, 20.0kg of iron oxide red, 15.0kg of titanium dioxide and Mica powder 10.0kg, after stirring, add 25.0kg of modified...

Embodiment 2

[0066] (1) Synthesis of modified epoxy resin: 29.7kg E-12, 29.7kg E-06, 0.6kg dimethylethanolamine and 20.0kg mixed solvent (10.0kg xylene, 5.0kg butyl acetate and 5.0kg Methyl isobutyl ketone) was added, after stirring evenly, 20.0kg of linoleic acid was added and the temperature was raised to 145°C, the temperature was kept until the acid value was ≤1.88mg KOH / g, the temperature was lowered to 27°C, and the modified epoxy resin was obtained after discharge.

[0067] (2) Preparation of peelable primer first component

[0068] First put the dispersant (1.0kg EFKA-4340, 2.0kg BYK-110), leveling agent (0.4kg BYK-388, 0.4kg BYK-320), defoamer (0.6kg BYK-051, 0.2kg BYK -A 530) and 7.0kg BYK-394 were added to 20.0kg of mixed solvent (5.0kg of propylene glycol methyl ether acetate, 10.0kg of butyl acetate and 5.0kg of butanone), and after stirring well, 20.0kg of iron oxide red and 10.0kg of titanium dioxide were added kg and mica powder 8.0kg, after stirring, add 30.0kg of modifie...

Embodiment 3

[0075] (1) Synthesis of modified epoxy resin: first 39.0kg E-12, 17.0kg E-03, 0.5kg dimethylethanolamine and 25.0kg mixed solvent (10.0kg cyclohexanone, 10.0kg butyl acetate and 5.0 kg kg methyl ethyl ketone), stir evenly, add 18.5kg linoleic acid and directly heat up to 150°C, keep warm until the acid value is less than or equal to 2.85mg KOH / g, cool down to 30°C, and discharge to obtain the modified epoxy resin.

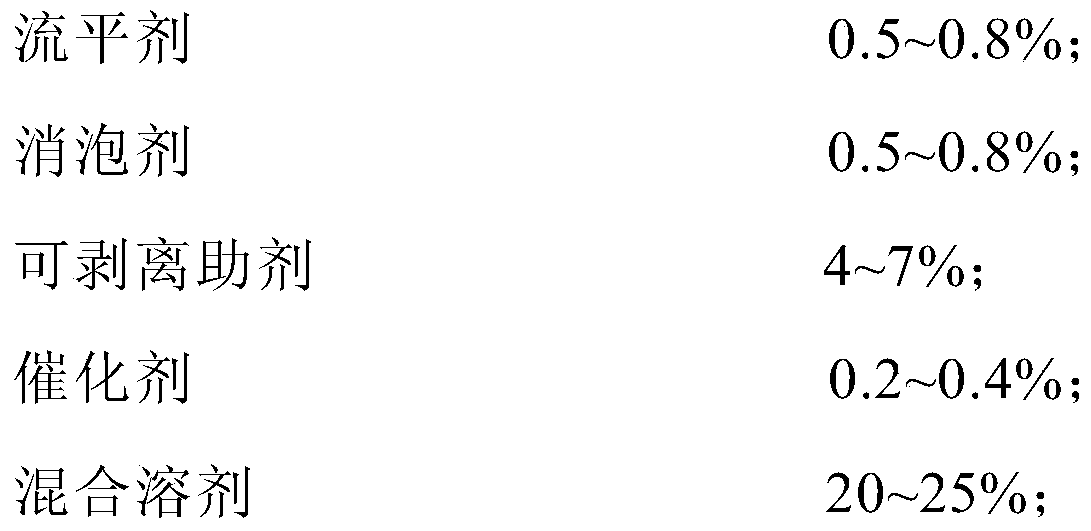

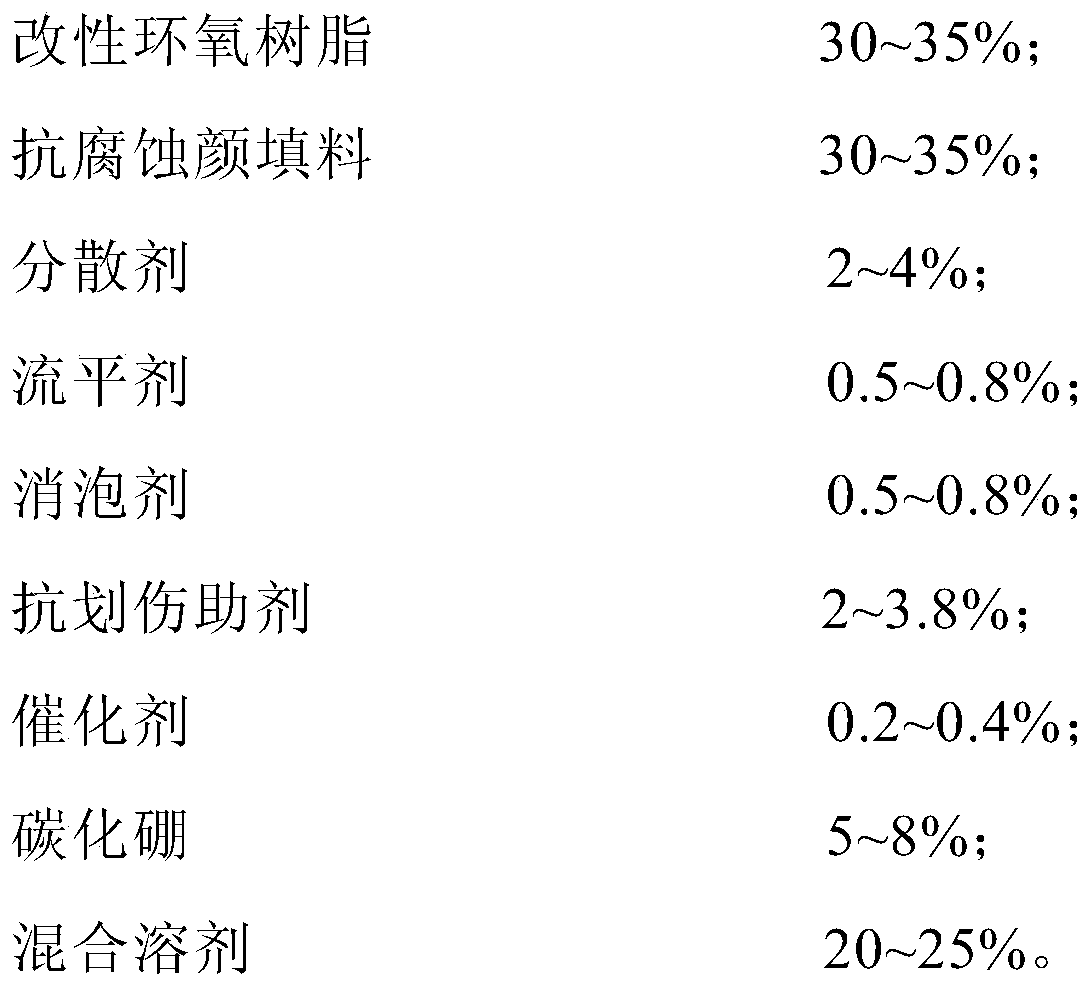

[0076] (2) Preparation of peelable primer A component

[0077] First, dispersant (2.0kgEFKA-4340, 1.5kg LACTIMON), leveling agent (0.3kg FEKA-3777, 0.3kg BYK-306), defoamer (0.3kg BYK-051, 0.3kg BYK-066N) and 6.0 Add 20.0kg of mixed solvent (5.0kg of propylene glycol methyl ether acetate, 10.0kg of methyl isobutyl ketone and 5.0kg of xylene) to kg TEGO PAD 2700, stir well and add 20.0kg of iron oxide red, 10.0kg of titanium dioxide and talc Powder 10.0kg, after stirring, add 29.0kg of modified epoxy resin that step 1) obtains, grind to fineness and be less than 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com