Manufacturing method for high-niobium TiAl system intermetallic compound and TC4 titanium alloy composite component

An intermetallic compound and composite component technology, which is applied in the field of preparation of high niobium TiAl intermetallic compounds and TC4 titanium alloy composite components, can solve problems such as inability to meet, and achieve efficient and reliable welding, high joint strength coefficient, and dense welding area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

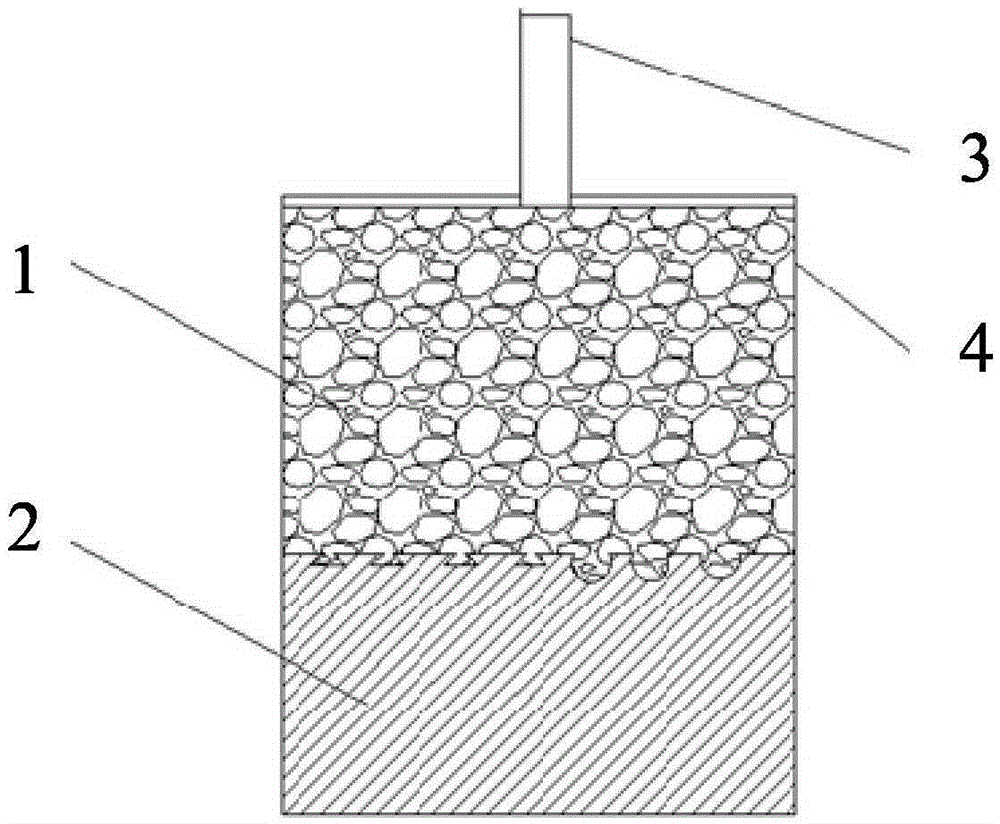

[0048] A method for manufacturing a high-niobium TiAl intermetallic compound and a TC4 titanium alloy composite component, comprising the following steps:

[0049] (1), according to the requirements of the component, the high niobium TiAl intermetallic compound Ti-45Al-8.5Nb-0.2W-0.3B-0.02Y (at%) (hereinafter referred to as Ti-45Al-8.5Nb-(W, B, Y)) The cast rod is processed into the required shape;

[0050] (2) The middle layer metal Ti-15Ni-15Cu is attached to the surface of Ti-45Al-8.5Nb-(W, B, Y) by electroplating or ion plating; the thickness is 150um.

[0051] (3) Put the processed Ti-45Al-8.5Nb-(W, B, Y) block and TC4 titanium alloy pre-alloyed powder into a 20# low-carbon steel ladle.

[0052] (4) Connect the bag to the vacuum unit and vacuumize at room temperature for 2 hours.

[0053] (5) The vacuum degree in the bag to be wrapped is better than 1.5×10 -3 After Pa, put the jacket into the heating furnace, slowly raise the temperature to 300°C, and keep it warm for ...

Embodiment 2

[0063] A method for manufacturing a high-niobium TiAl intermetallic compound and a TC4 titanium alloy composite component, comprising the following steps:

[0064] (1) According to the requirements of the component, process the high-niobium TiAl intermetallic compound Ti-45Al-8Nb (at%) powder metallurgy rod into the required form;

[0065] (2) Put the treated Ti-45Al-8Nb block and TC4 titanium alloy pre-alloyed powder into the stainless steel 1Cr18Ni9Ti sheathed steel ladle.

[0066] (3) Connect the bag to the vacuum unit and vacuumize at room temperature for 2 hours.

[0067] (4) The vacuum degree in the bag to be wrapped is better than 1×10 -3 After Pa, put the jacket into the heating furnace, slowly raise the temperature to 300°C, and keep it warm for 3h. The vacuum degree in the package is better than 2×10 -3 After Pa, the temperature of the jacket was raised to 780°C, and the holding time was 9h.

[0068] (5) The vacuum degree in the bag to be wrapped is better than 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com