Preparation method for electro polymerization membrane comprising thienyl mononuclear ruthenium complex and photo electrochemical properties

A ruthenium complex, thienyl ruthenium technology, applied in the field of electrochemistry, can solve the problems of hindered, electrochemically unstable charge transport of polymeric materials, etc., and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the preparation of ligand L

[0021] The synthetic route of ligand L is as follows:

[0022]

[0023] Compound 1 was prepared according to the literature [Z.H.Peng, A.R.Gharavi, L.P.Yu, Synthesis and characterization of photorefractive polymers containing transition metal complexes photosensitizer, J. Am. Chem. Soc., 1997, 119(20), 4622-4632.].

[0024] Compound 1 (0.33g, 0.72mmol) and thiophenecarbaldehyde (0.188g, 1.68mmol) were dissolved in 10ml of tetrahydrofuran, and under a nitrogen atmosphere, 10ml of t-BuOK (0.18g) suspension was slowly added dropwise to In the above solution, the solution changed from light yellow to dark red at this time, and the upper liquid surface glowed blue. After the dropwise addition, continue to stir at room temperature for 12h, and the system turns bright yellow. After the reaction was completed, the reaction system was poured into 300ml of dichloromethane, washed with water three times, dried over sodium sulfate an...

Embodiment 2

[0026] Embodiment two, ruthenium complex [Ru(bpy) 2 L](ClO 4 ) 2 preparation of

[0027] Ruthenium complex [Ru(bpy) 2 L](ClO 4 ) 2 The synthetic route of is as follows:

[0028]

[0029] Ru(bpy) 2 Cl 2 According to the literature [Z.Q.Ji, S.D.Huang, A.R.Guadalupe., Synthesis, X-ray structures, spectroscopic and electrochemical properties of ruthenium (II) complexes containing 2, 2'-bipyrimidine. Inorg. Chim. Acta, 2000, 305, 127-134.] method preparation.

[0030] Dissolve 50mg (0.19mmol) of Ligand L in 6ml of DMF, then add 10ml of ethanol and 88mg (0.23mmol) of Ru(bpy) 2 Cl 2 , N 2 Heating to reflux under protection for 20 hours, cooling to room temperature, suction filtration to remove unreacted ligands, spin out the ethanol in the filtrate, add sodium perchlorate aqueous solution to it, suction filtration to collect the precipitate, and vacuum dry the precipitate Then add a small amount of acetonitrile to dissolve it, then peroxide column, the developer is dichlo...

Embodiment 3

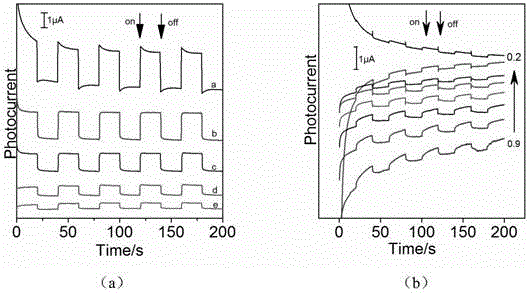

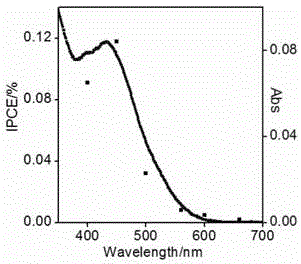

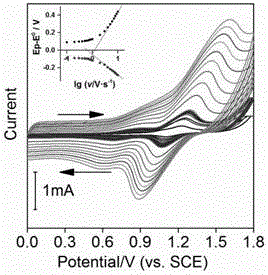

[0034] Embodiment three, the preparation of ruthenium complex electropolymerization thin film

[0035] 1. Clean indium-tin oxide (ITO) conductive glass. The ITO glass was cut into small pieces of 1.5 cm x 5 cm. Sequentially use detergent, one time of water ultrasonic cleaning three times each, each time for 5 minutes, and finally use concentrated ammonia water: hydrogen peroxide: primary water = 1:1:5 (v:v:v) in a mixed solution of 70°C for half an hour . After taking it out, use water to ultrasonically clean it again, and finally use the ear washing ball to dry it and put it into a small bottle, and dry it for later use.

[0036] 2. Dissolve the ruthenium complex in 0.1M tetrabutylammonium hexafluorophosphate dichloromethane solution, the concentration of the ruthenium complex is 1mM, use ITO as the working electrode, the platinum electrode as the counter electrode, and the silver wire as the reference electrode, N into the solution 2 , pass 15min, after the end, with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com