Method for preparing three-dimensional porous nanometer silicon at low temperature through molten-salt growth method

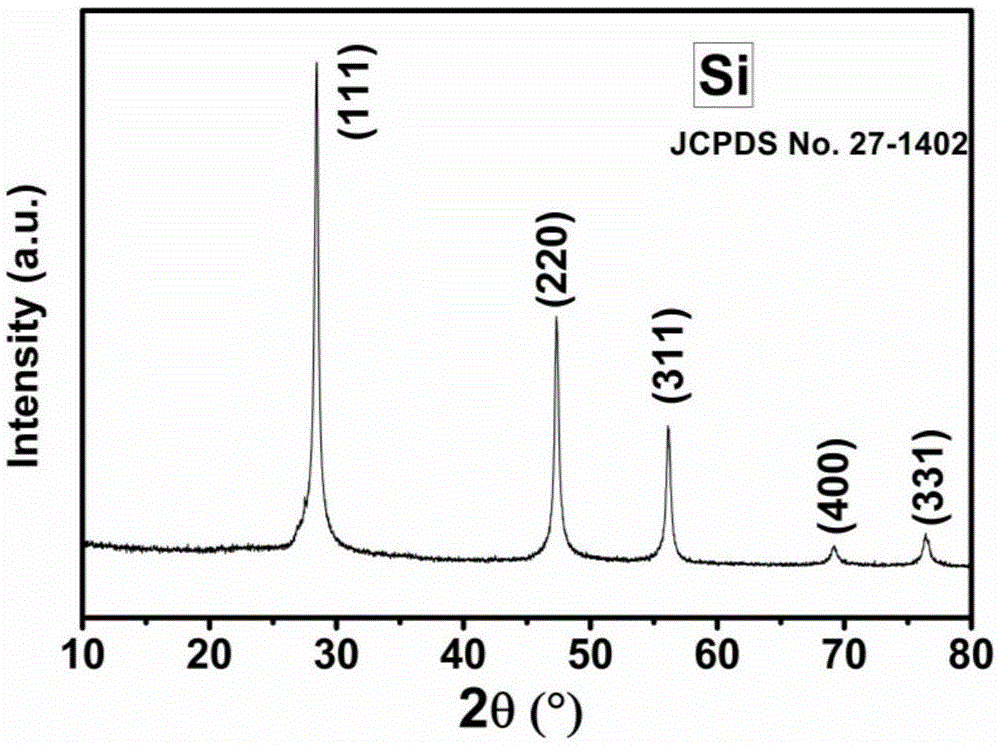

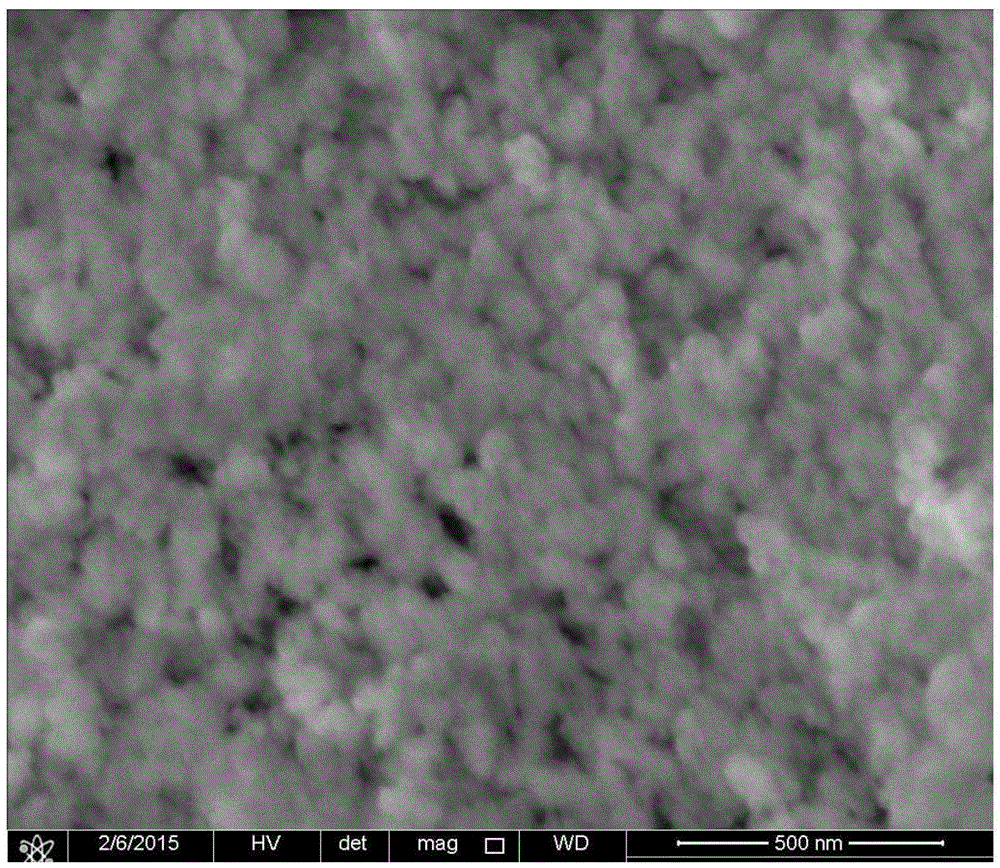

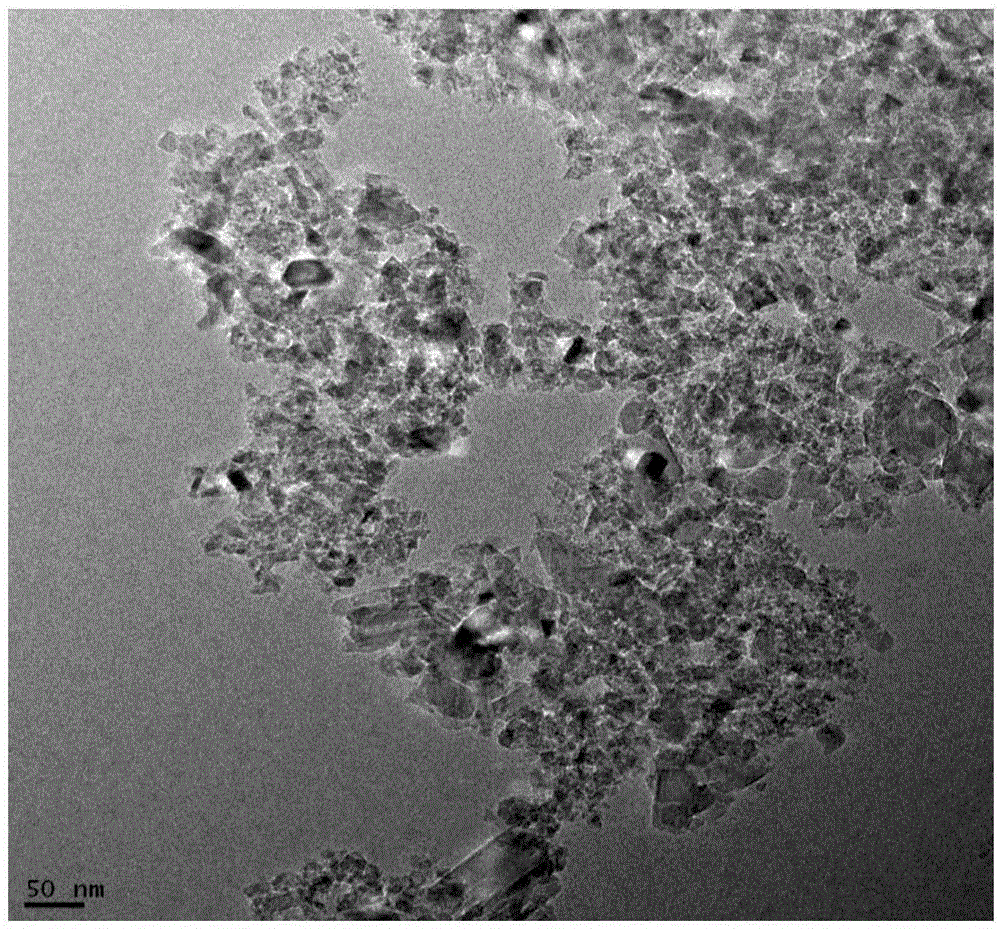

A three-dimensional porous and nano-silicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as complex steps, pollution, and harsh conditions, and achieve the effect of uniform particles, high purity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Put 1.2g of silicon dioxide granules obtained by rice husk processing into a sealed stainless steel high-temperature kettle after mixing evenly with 2g of magnesium powder;

[0025] (2) Put the mixture in (1) into a tube furnace filled with argon inert gas and heat it to 650°C at a heating rate of 5°C / min and keep it warm for 6h to obtain the product. After the product is cooled to room temperature with the furnace, take it out;

[0026] (3) 2g of the resulting product magnesium silicide and 7g of anhydrous zinc chloride (ZnCl 2 ) after mixing evenly, put it into a stainless steel high-temperature kettle again, put the mixture into a tube furnace filled with argon inert gas, and heat it to 300°C at a heating rate of 10°C / min and keep it for 10h. After the product is cooled to room temperature with the furnace, take it out ;

[0027] (4) Pickling the product obtained in (3) with 1 mol / L hydrochloric acid to remove magnesium oxide, magnesium chloride, and elemental m...

Embodiment 2

[0030] (1) 1.2g of silicon dioxide granules obtained by rice husk processing and 1.2g of magnesium powder are mixed evenly and put into a sealed stainless steel high-temperature kettle;

[0031] (2) Put the mixture in (1) into a tube furnace filled with argon inert gas and heat it to 400°C for 1 hour at a heating rate of 10°C / min to obtain the product, and take it out after the product is cooled to room temperature with the furnace;

[0032] (3) 1g of the resulting product magnesium silicide and 7g of anhydrous zinc chloride (ZnCl 2 ) after mixing evenly, put it into a stainless steel high-temperature kettle again, put the mixture into a tube furnace filled with argon inert gas, heat it to 100°C at a heating rate of 5°C / min and keep it for 2h, and take it out after the product is cooled to room temperature with the furnace ;

[0033] (4) Pickling the product obtained in (3) with 1 mol / L hydrochloric acid to remove magnesium oxide, magnesium chloride, and elemental metal Zn, w...

Embodiment 3

[0035] (1) Mix 1.2 g of silicon dioxide particles obtained by straw treatment with 2 g of magnesium powder and put them into a sealed stainless steel high-temperature kettle;

[0036] (2) Put the mixture in (1) into a tube furnace filled with argon inert gas and heat it to 500°C at a heating rate of 1°C / min for 3 hours to obtain the product, and take it out after the product is cooled to room temperature with the furnace;

[0037] (3) 1g of the resulting product magnesium silicide and 10g of anhydrous aluminum chloride (AlCl 3 ) after mixing evenly, put it into a stainless steel high-temperature kettle again, put the mixture into a tube furnace filled with argon inert gas and heat it to 200°C at a heating rate of 10°C / min and keep it warm for 12h. After the product is cooled to room temperature with the furnace, take it out ;

[0038] (4) Wash the product obtained in (3) with 1 mol / L hydrochloric acid to remove magnesium oxide, magnesium chloride, and elemental metal Al, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com