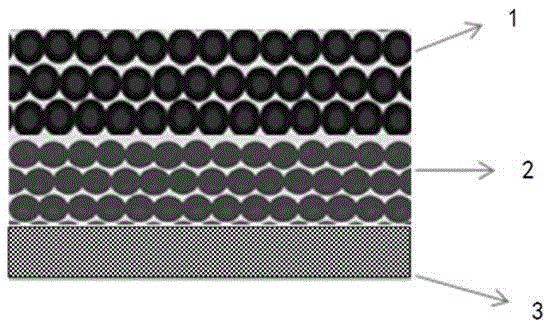

Chalcogenide semi-solid lithium battery and preparing method thereof

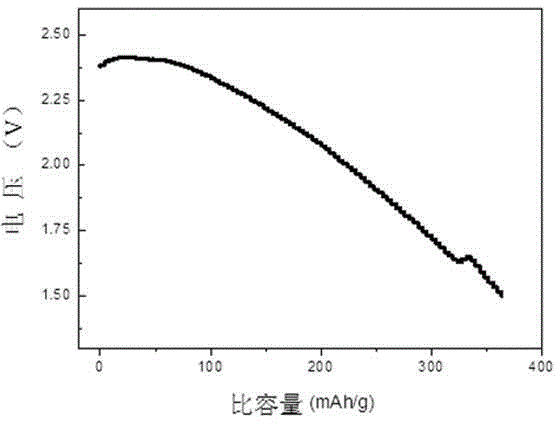

A semi-solid and lithium battery technology, applied in the manufacture of lithium batteries, electrolyte batteries, secondary batteries, etc., can solve the problems of low ionic conductivity and low capacity, achieve large specific surface area, improve practicability, and high gram capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Zeolite pretreatment: 10g sodium zeolite powder (AlNaO 6 Si 2 , molecular weight 202.10) dispersed in 150-250ml concentration of 3M lithium nitrate (LiNO 3 ) aqueous solution, stirred magnetically at room temperature for 12-24 hours, then filtered under reduced pressure, washed three times with deionized water, dried and heat-treated in a muffle furnace for 4 hours at 400-450°C for later use. The treated zeolite is high-energy dry ball milled at a speed of 400 r / min for 2-8 hours to obtain white flour-like pretreated zeolite powder.

[0040] (2) Preparation of lithium-containing salt polymer: weigh a certain mass of lithium trifluoromethanesulfonate (LiCF 3 SO 3 ), dispersed in polyethylene glycol 400 (PEG400) solvent, magnetic stirring for 12~24h, to lithium trifluoromethanesulfonate (LiCF 3 SO 3 ) completely dissolved to obtain lithium trifluoromethanesulfonate (LiCF 3 SO 3 ) a polyethylene glycol 400 (PEG400) solution with a mass fraction of 6-12 wt%.

[...

Embodiment 2

[0045] (1) Zeolite pretreatment: Disperse 10g of ferrierite powder (FER) in 150-250ml of 3M lithium perchlorate (LiClO 4 ) aqueous solution, stirred magnetically at room temperature for 24-36 hours, then filtered under reduced pressure, washed three times with deionized water, dried and heat-treated in a muffle furnace for 4 hours at 400-450°C for later use. The treated zeolite is high-energy dry ball milled at a speed of 400 r / min for 2-8 hours to obtain white flour-like pretreated zeolite powder.

[0046] (2) Preparation of lithium-containing salt polymer: Weigh a certain mass of lithium perchlorate (LiClO 4 ), dispersed in polyethylene glycol 400 (PEG400) solvent, magnetic stirring for 12~24h, to lithium perchlorate (LiClO 4 ) completely dissolved to obtain lithium perchlorate (LiClO 4 ) a polyethylene glycol 400 (PEG400) solution with a mass fraction of 10-16 wt%.

[0047] (3) Preparation of semi-solid electrolyte: pretreated zeolite and 10~16wt% lithium perchlorate (Li...

Embodiment 3

[0051] (1) Zeolite pretreatment: 10g sodium zeolite powder (AlNaO 6 Si 2 , molecular weight 202.10) dispersed in 150-250ml concentration of 3M lithium nitrate (LiNO 3 ) aqueous solution, stirred magnetically at room temperature for 12-24 hours, then filtered under reduced pressure, washed three times with deionized water, dried and heat-treated in a muffle furnace for 4 hours at 400-450°C for later use. The treated zeolite is high-energy dry ball milled at a speed of 400 r / min for 2-8 hours to obtain flour-like pretreated zeolite powder.

[0052] (2) Preparation of lithium-containing salt polymer: weigh a certain mass of lithium trifluoromethanesulfonate (LiCF 3 SO 3 ), dispersed in polyethylene glycol 400 (PEG400) solvent, magnetic stirring for 12~24h, to lithium trifluoromethanesulfonate (LiCF 3 SO 3 ) completely dissolved to obtain lithium trifluoromethanesulfonate (LiCF 3 SO 3 ) a polyethylene glycol 400 (PEG400) solution with a mass fraction of 6-12 wt%.

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com