Coating and preparation method thereof

A technology of coatings and mass parts, applied in polyester coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve the problems of coatings that are not resistant to oil, moisture and cracking, and achieve environmental protection, low cost, and high stability The effect of sex and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

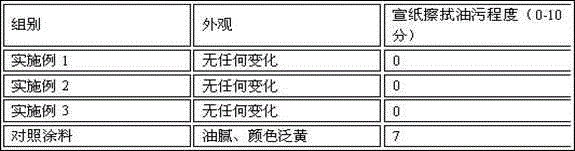

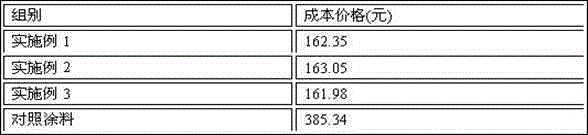

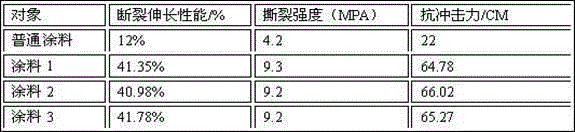

Examples

Embodiment 1

[0017] The present invention is a kind of paint, wherein, it is made from the following raw materials: polyvinyl tertiary carbonate 60g, maleic acid resin 80g, monomethoxy polyethylene glycol butyraldehyde 40g, isoprene glycol 80g, β-sitosterol 18.2g, methyl sterol 18.2g, stigmasterol 3.6g, polyethylene terephthalate 80g, escargot shell powder 30g, 4′,4″-dihydroxy-2-formic acid-triphenylmethane 50g, E -20 epoxy resin 36.4g, E-42 epoxy resin 36.4g, E-06 epoxy resin 7.2g, montmorillonite 30g, light powder 20g, lime 20g, trimethylolpropane three (3- aziridine Propionate) 50g, cyanoguanidine 40g and titanium dioxide 30g. The snail shell powder is the shell of the powdered snail family animal round snail.

[0018] Its preparation method is:

[0019] Step 1: Mix 80g of maleic acid resin, 40g of monomethoxypolyethylene glycol butyraldehyde, 80g of polyethylene terephthalate, 36.4g of E-20 epoxy resin, and 36.4g of E-42 epoxy resin , 7.2g of E-06 epoxy resin and 40g of cyanoguanidin...

Embodiment 2

[0023] The present invention is a kind of paint, wherein, it is made from the following raw materials: polyvinyl tertiary carbonate 130g, maleic acid resin 130g, monomethoxy polyethylene glycol butyraldehyde 90g, isoprene glycol 100g, β-sitosterol 28g, methyl sterol 28g, stigmasterol 14g, polyethylene terephthalate 130g, escargot shell powder 80g, 4′,4″-dihydroxy-2-formic acid-triphenylmethane 80g, E-20 ring Oxygen resin 56.5g, E-42 epoxy resin 17g, E-06 epoxy resin 56.5g, montmorillonite 50g, light powder 40g, lime 40g, trimethylolpropane tris (3- aziridinyl propionate ) 100g, 70g of cyanoguanidine and 50g of titanium dioxide. The snail shell powder is the shell of the round snail of the snail family animal in powder form.

[0024] Its preparation method is:

[0025] Step 1: 130g of maleic acid resin, 90g of monomethoxy polyethylene glycol butyraldehyde, 130g of polyethylene terephthalate, 56.5g of E-20 epoxy resin, 17g of E-42 epoxy resin, Mix 56.5g of E-06 epoxy resin and...

Embodiment 3

[0029] The present invention is a kind of paint, wherein, it is prepared from the following raw materials: polyvinyl tertiary carbonate 80g, maleic acid resin 100g, monomethoxy polyethylene glycol butyraldehyde 60g, isoprene glycol 90g, steroid mixture 60g , β-sitosterol 22.5g, methylsterol 30g, stigmasterol 7.5g, polyethylene terephthalate 120g, snail shell powder 50g, 4′,4″-dihydroxy-2-formic acid-triphenyl Methane 60g, E-20 epoxy resin 38.6g, E-42 epoxy resin 12.8g, E-06 epoxy resin 38.6g, montmorillonite 40g, light powder 30g, lime 30g, trimethylolpropane tri(3 - aziridinyl propionate) 70g, cyanoguanidine 50g and titanium dioxide 40g. The snail shell powder is the shell of the powdered snail family animal round snail.

[0030] Its preparation method is:

[0031] Step 1: Mix 100g of maleic acid resin, 60g of monomethoxypolyethylene glycol butyraldehyde, 120g of polyethylene terephthalate, 38.6g of E-20 epoxy resin, and 12.8g of E-42 epoxy resin , 38.6g of E-06 epoxy resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com