Low-temperature sintering nano-silver paste and preparation process thereof

A nano-silver paste and low-temperature sintering technology, which is applied in the direction of nanotechnology, can solve the problems of resin matrix fatigue failure, chip heat dissipation and physical properties, and chip failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

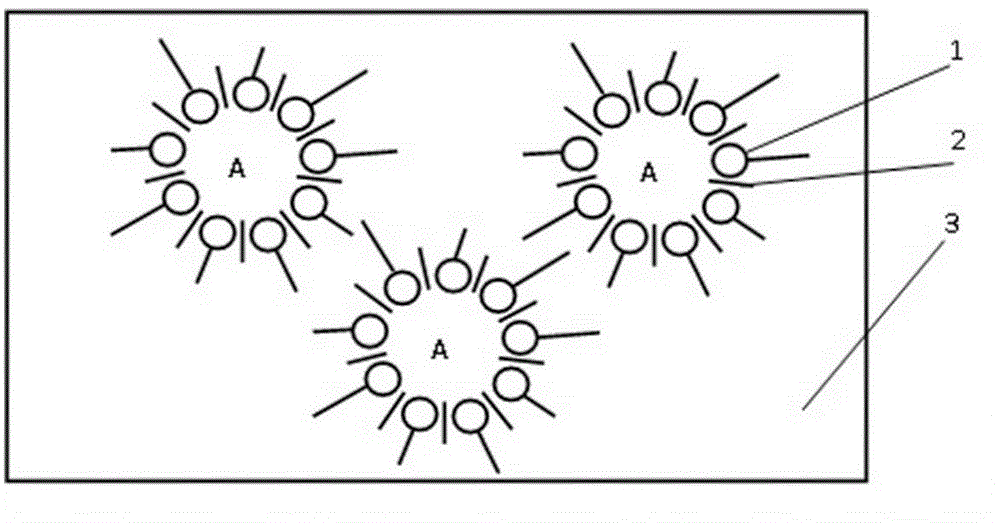

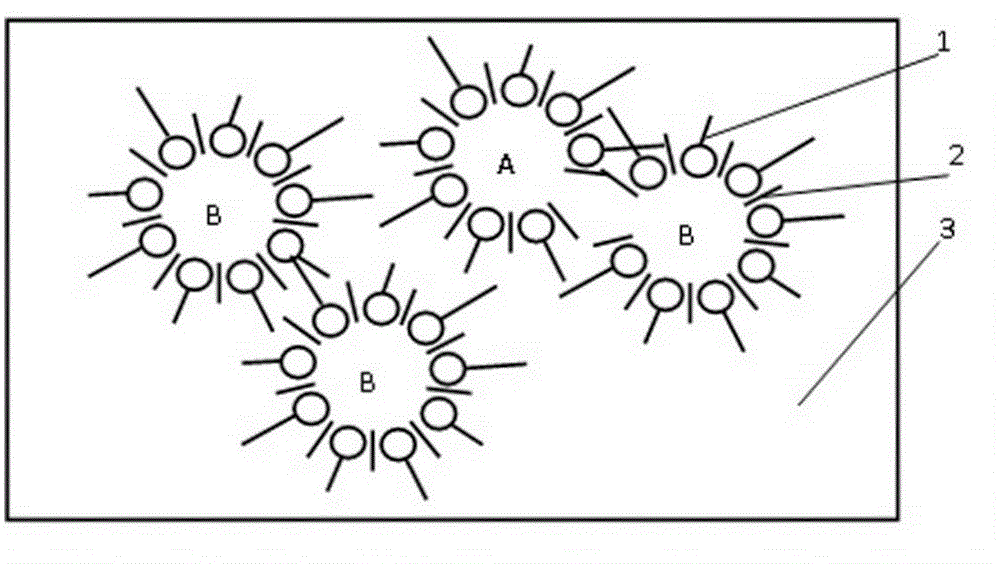

Image

Examples

Embodiment

[0041]A preparation process for low-temperature sintering nano-silver paste, comprising the steps of:

[0042] 1) Prepare a blank inverse microemulsion and make a pseudo-ternary phase diagram:

[0043] Span 80: Triton X-100 with different mass ratios 3:7, 1:4, 1:5, 1:6, 1:7, 1:8, Span 80 and Triton X-1001: The mass ratio of n-hexanol 2 is 2:1, the total mass of Span 80, Triton X-100 and n-hexanol 2: the mass ratio of n-heptane 3 is 1:1, Span 80, Triton X- 100. Add n-hexanol 2 and n-heptane 3 to each colorimetric tube in sequence according to the corresponding proportion, add distilled water dropwise while stirring at 30°C to prepare a blank reversed-phase microemulsion, and determine Span 80 and The best mass ratio K1 of Triton X-1001 is 1:5;

[0044] Span 80: The mass ratio of Triton X-100 is 1:5. The compound surfactant and n-hexanol 2 take different mass ratios of 3:1, 2:1, 1:1, 1:2, Span 80. The total mass of Triton X-100 and n-hexanol 2: the mass ratio of n-heptane 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com