A kind of preparation method of corrosion-resistant fuel cell gas diffusion layer

A gas diffusion layer and fuel cell technology, which is applied in the direction of fuel cells, electrical components, battery electrodes, etc., to achieve the effects of easier operation, improved corrosion resistance and stability, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

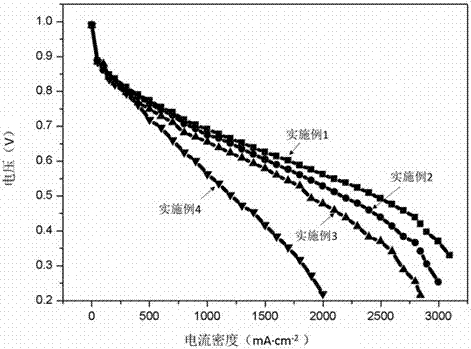

Embodiment 1

[0029] Dissolve polyvinylpyrrolidone (PVP) in deionized water, and the mass ratio of PVP to deionized water is 1:1999 (that is, the mass percentage of PVP in the solution is 0.5‰); measure 15 ml of the solution, and add two Tin oxide (SnO 2 ) nanopowder and indium oxide (In 2 o 3 ) A total of 75 mg of nano powder (ie SnO 2 and In 2 o 3 The mass percentage of nano powders in the total solution is 0.5%), fully mechanically stirred for 0.5 hours, and then ultrasonically dispersed for 30 minutes to form a uniform suspension; then add polytetrafluoroethylene (PTFE) with a mass fraction of 10% to it A total of 30 mg of emulsion (i.e. the mass of PTFE as SnO 2 and In 2 o 3 4% of the total mass of the nanometer powder), stirred slowly for 10 minutes to form a microporous layer slurry; prepare a carbon fiber paper with a porosity of 30% and a thickness of 190 microns as the support layer, and use the prepared microporous layer slurry The glass rod is rolled onto one side of the...

Embodiment 2

[0032] Dissolve alkylphenol polyoxyethylene ether (APEO) in deionized water, and the mass ratio of APEO to deionized water is 1:666 (that is, the mass percentage of APEO in the solution is 1.5‰); measure 15 ml of the solution, Add a total of 464 mg of fluorine-doped tin dioxide (FTO) nanopowder to it (that is, the mass percentage of FTO nanopowder in the total solution is 3%), fully mechanically stir for 1 hour, and then ultrasonically disperse for 40 minutes to form a uniform suspension liquid; adding thereto a total of 462 mg of tetrafluoroethylene and hexafluoropropylene copolymer (FEP) emulsion with a mass fraction of 10% (that is, the quality of FEP is 10% of the FTO nano-powder quality), and stirred slowly for 15 minutes, Form the microporous layer slurry; prepare a carbon fiber paper with a porosity of 45% and a thickness of 200 microns as a support layer, and roll the prepared microporous layer slurry onto one side of the carbon fiber paper support layer with a glass ro...

Embodiment 3

[0035] Dissolve polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (PEO-PPO-PEO) in deionized water, and the mass ratio of PEO-PPO-PEO to deionized water is 1:332 (that is, PEO-PPO -PEO accounted for the mass percent of the solution is 3 ‰); measure 15 milliliters of the solution, to which 789 mg of aluminum-doped zinc dioxide (AZO) nanopowder was added (that is, the mass percent of AZO nanopowder accounted for the total solution was 5 %), fully mechanically stirred for 1 hour, and then ultrasonically dispersed for 50 minutes to form a uniform suspension; then add 1.58 grams of polyvinylidene fluoride (PVDF) emulsion with a mass fraction of 10% (that is, the mass of PVDF is AZO nano 20% of the mass of the powder), stirred slowly for 20 minutes until uniform to form a microporous layer slurry; prepare a carbon fiber paper with a porosity of 60% and a thickness of 150 microns as the support layer, and use the prepared microporous layer slurry The glass rod is rolled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com