Negative plate used for lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as consumption, long process, and impact on battery performance, and achieve the effects of increasing battery capacity, excellent conductivity, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

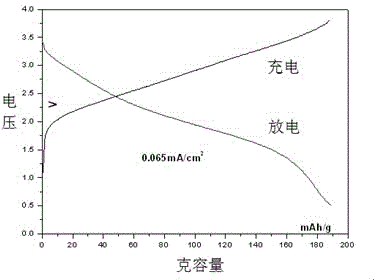

[0074] Example 1: V 2 o 5 Positive electrode versus Li-Si-Cu integrated negative electrode

[0075] V 2 o 5 Preparation of positive electrode sheet: mixed positive electrode material V 2 o 5 (0.800g), conductive carbon black (0.100g), PVDF (0.100g) and NMP (2.00g) to prepare slurry, coated on aluminum foil to make pole piece (pole piece thickness 125μm), then dried, pole piece cut It is used as a 15mm disc, and compacted under 2.0MPa after slicing.

[0076] Negative electrode sheet preparation: weigh 0.0300g of Li in a glove box under an argon atmosphere 13 Si 4 Powder, 0.1200g of copper powder are evenly mixed and pressed into a mold with a diameter of 14.0mm (10.0MPa) to make a negative electrode sheet, and then mixed with V 2 o 5 The battery is assembled with the positive plate, and the test results of the battery are as follows: figure 1 And shown in Table 1.

[0077] Button battery charging and discharging data in table 1, embodiment 1.

[0078] ...

Embodiment 2

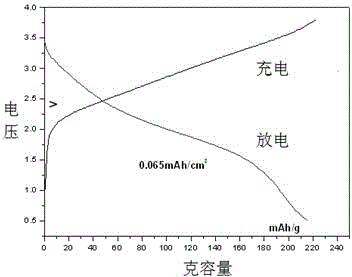

[0080] Example 2: V 2 o 5 Positive electrode to Li-Si-Cu integrated negative electrode:

[0081] V 2 o 5 Preparation of positive electrode sheet: mixed positive electrode material V 2 o 5 (0.800g), conductive carbon black (0.100g), PVDF (0.100g) and NMP (2.00g) to prepare slurry, coated on aluminum foil to make pole piece (pole piece thickness 125μm), then dried, pole piece cut It is used as a 15mm disc, and compacted under 2.0MPa after slicing.

[0082] Negative electrode sheet preparation: under an argon atmosphere in the glove box, weigh 0.0800g of Cu powder, 0.0100g of lithium powder, and 0.0100g of silicon powder and mix them evenly into a copper foam matrix with a diameter of 14mm. Negative sheet is made by pressing sheet (10.0MPa) in the mold, and then with V 2 o 5 The battery is assembled with the positive plate, and the test results of the battery are as follows: figure 2 and shown in Table 2.

[0083] Button battery charging and discharging data in t...

Embodiment 3

[0086] Example 3: V 2 o 5 Positive electrode to Li-Si-Cu integrated negative electrode:

[0087] V 2 o 5 Preparation of positive electrode sheet: mixed positive electrode material V 2 o 5 (0.800g), conductive carbon black (0.100g), PVDF (0.100g) and NMP (2.00g) to prepare slurry, coated on aluminum foil to make pole piece (pole piece thickness 125μm), then dried, pole piece cut It is used as a 15mm disc and compacted under 2.0MPa after the blade.

[0088] Negative electrode sheet preparation: weigh 0.0800g of Cu powder and 0.0200g of Li 13 Si 4 Mix the powder evenly and put it into a foamed copper matrix with a diameter of 14mm, and press it into a mold with a diameter of 14.0mm (10.0MPa) to make a negative electrode sheet, and then mix it with V 2 o 5 The battery is assembled with the positive plate, and the test results of the battery are as follows: image 3 and shown in Table 3.

[0089] Button battery charging and discharging data in table 3, embodiment 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com