Preparation technology of PBT (polybutylene terephthalate)-regenerated PET (polyethylene glycol terephthalate) modified stretch yarn

A preparation process and modification technology, applied in rayon manufacturing, conjugated synthetic polymer rayon, fiber chemical characteristics, etc., can solve the problems of molecular weight reduction, poor impact performance of products, low intrinsic viscosity coefficient, etc., and achieve performance The effect of index improvement, excellent elastic performance, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

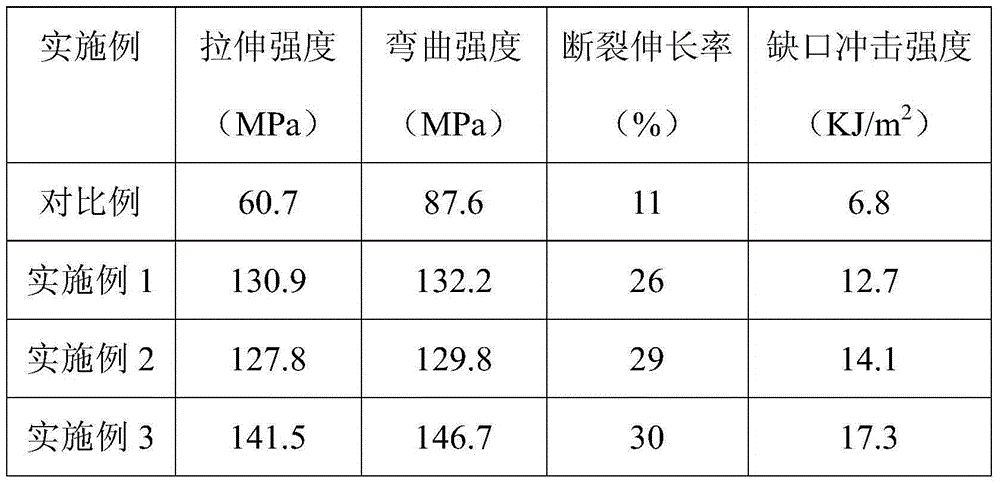

Examples

Embodiment 1

[0026] (1) Wash the mineral water bottle to remove non-PET materials, and prepare recycled PET slices after being crushed by a crusher, washed, dried, extruded and granulated;

[0027] (2) The regenerated PET slices, the CaCO with a diameter of 30nm that accounts for 5% of the mass fraction of the regenerated PET slices 3 The powder and the aluminate coupling agent accounting for 4% of the mass fraction of recycled PET chips are placed in a mixer, the temperature is controlled at 180°C, and nitrogen is filled for 0.5h, and then extruded and granulated by a twin-screw extruder to obtain improved Sexually regenerated PET;

[0028] (3) First, dry the modified regenerated PET and PBT at 120°C for 2h. In parts by weight, 50 parts of modified regenerated PET, 60 parts of PBT, 3 parts of maleic anhydride grafted styrene, and 0.3 parts of phosphite Amine and 4 parts of thermoplastic polyester elastomer were placed in a mixer and mixed, the temperature was controlled at 240°C, mixed f...

Embodiment 2

[0031] (1) Wash the mineral water bottle to remove non-PET materials, and prepare recycled PET slices after being crushed by a crusher, washed, dried, extruded and granulated;

[0032] (2) The regenerated PET slices, the CaSiO 20nm diameter that accounts for 9% of the regenerated PET slice mass fraction 3 The powder and the titanate coupling agent accounting for 3% of the mass fraction of recycled PET chips are placed in a mixer, the temperature is controlled at 200 ° C, mixed with nitrogen for 1 hour, and modified by extruding and granulating through a twin-screw extruder recycled PET;

[0033] (3) firstly dry modified regenerated PET and PBT at 110°C for 1h, in parts by weight, 30 parts of modified regenerated PET, 50 parts of PBT, 5 parts of acrylonitrile-styrene-maleic anhydride terpolymer, 0.5 parts of silicone oil and 5 parts of thermoplastic polyester elastomer were mixed in a mixer, the temperature was controlled at 260°C, mixed for 3 hours, extruded and granulated by...

Embodiment 3

[0036] (1) Wash the mineral water bottle to remove non-PET materials, and prepare recycled PET slices after being crushed by a crusher, washed, dried, extruded and granulated;

[0037] (2) CaSO with a diameter of 40nm that accounts for 10% of the mass fraction of regenerated PET slices and regenerated PET slices 4 The powder and aluminate coupling agent accounting for 5% of the mass fraction of recycled PET chips are placed in a mixer, the temperature is controlled at 180 ° C, mixed with nitrogen for 1 hour, and modified by extruding and granulating through a twin-screw extruder recycled PET;

[0038] (3) First, dry the modified regenerated PET and PBT at 140°C for 1h. In parts by weight, mix 50 parts of modified regenerated PET, 70 parts of PBT, 4 parts of PETG, 0.8 parts of phosphite amine, and 5 parts of thermoplastic The polyester elastomer was mixed in a mixer, the temperature was controlled at 260°C, mixed for 3 hours, and extruded and granulated by a twin-screw extruder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com