Preparation method of thermal conductive electrical insulating material

A heat-conducting insulating material, high-density polyethylene technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of reduced product efficacy and shortened life, and achieve good mechanical properties and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

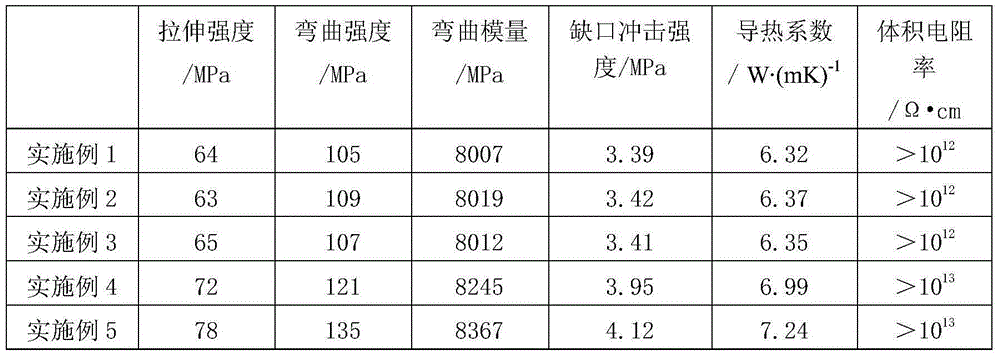

Examples

Embodiment 1

[0017] A method for preparing a thermally conductive insulating material, comprising the steps of:

[0018] Step 1, in parts by weight, take 20 parts of high-density polyethylene, 10 parts of linear low-density polypropylene, 4 parts of nitrile rubber, 1 part of dibutyl sebacate, 2 parts of ethyl acetoacetate, two parts of methacrylic acid 1 part of methyl amino ethyl ester, 3 parts of polyamide resin, 2 parts of polyvinyl acetate, 2 parts of hydroxyl silicone oil, 1 part of talcum powder, 2 parts of stearic acid, 3 parts of alumina fiber, 1 part of coupling agent KH-5501, Heat and stir to mix;

[0019] Step 2, ball milling and drying the mixed material obtained in step 1 to obtain a dried product;

[0020] Step 3, add the dried product obtained in step 2 into a twin-screw extruder, extrude, granulate, and cool to obtain.

[0021] In step 1, the heating temperature is 50° C., and the stirring speed is 400 rpm.

[0022] In step 3, the extrusion temperature of the twin-screw ...

Embodiment 2

[0024] A method for preparing a thermally conductive insulating material, comprising the steps of:

[0025] Step 1, in parts by weight, take 23 parts of high-density polyethylene, 17 parts of linear low-density polypropylene, 6 parts of nitrile rubber, 2 parts of dibutyl sebacate, 4 parts of ethyl acetoacetate, two parts of methacrylic acid 5 parts of methyl amino ethyl ester, 5 parts of polyamide resin, 5 parts of polyvinyl acetate, 6 parts of hydroxyl silicone oil, 3 parts of talcum powder, 4 parts of stearic acid, 7 parts of alumina fiber, 3 parts of coupling agent KH-5503, Heat and stir to mix;

[0026] Step 2, ball milling and drying the mixed material obtained in step 1 to obtain a dried product;

[0027] Step 3, add the dried product obtained in step 2 into a twin-screw extruder, extrude, granulate, and cool to obtain.

[0028] In step 1, the heating temperature is 65° C., and the stirring speed is 300 rpm.

[0029] In step 3, the extrusion temperature of the twin-sc...

Embodiment 3

[0031] A method for preparing a thermally conductive insulating material, comprising the steps of:

[0032] Step 1, in parts by weight, take 30 parts of high-density polyethylene, 20 parts of linear low-density polypropylene, 7 parts of nitrile rubber, 5 parts of dibutyl sebacate, 5 parts of ethyl acetoacetate, dimethacrylate 6 parts of methyl amino ethyl ester, 7 parts of polyamide resin, 6 parts of polyvinyl acetate, 7 parts of hydroxyl silicone oil, 5 parts of talcum powder, 6 parts of stearic acid, 8 parts of alumina fiber, 3 parts of coupling agent KH-5503, Heat and stir to mix;

[0033] Step 2, ball milling and drying the mixed material obtained in step 1 to obtain a dried product;

[0034] Step 3, add the dried product obtained in step 2 into a twin-screw extruder, extrude, granulate, and cool to obtain.

[0035] In step 1, the heating temperature is 65° C., and the stirring speed is 300 rpm.

[0036] In step 3, the extrusion temperature of the twin-screw extruder is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com