A kind of blister copper fire refining furnace and refining process

A technology of pyro-refining and blister copper, which is applied in the field of metallurgy, can solve problems such as excessive flue gas leakage, poor agitation circulation of copper liquid, large labor load and labor intensity, etc., and achieves reduced equipment purchase costs, uniform radial temperature distribution, The effect of sufficient heat exchange of cold material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

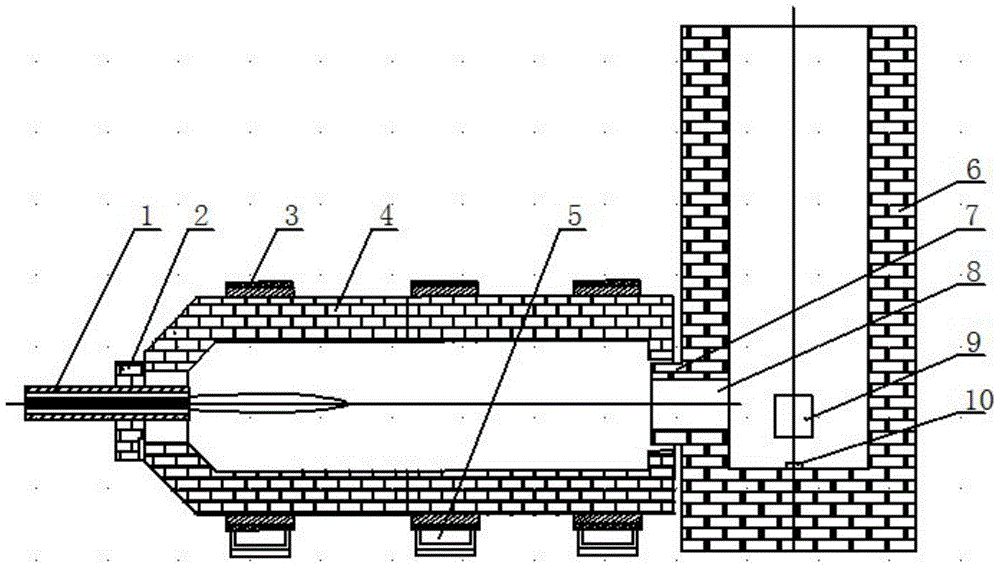

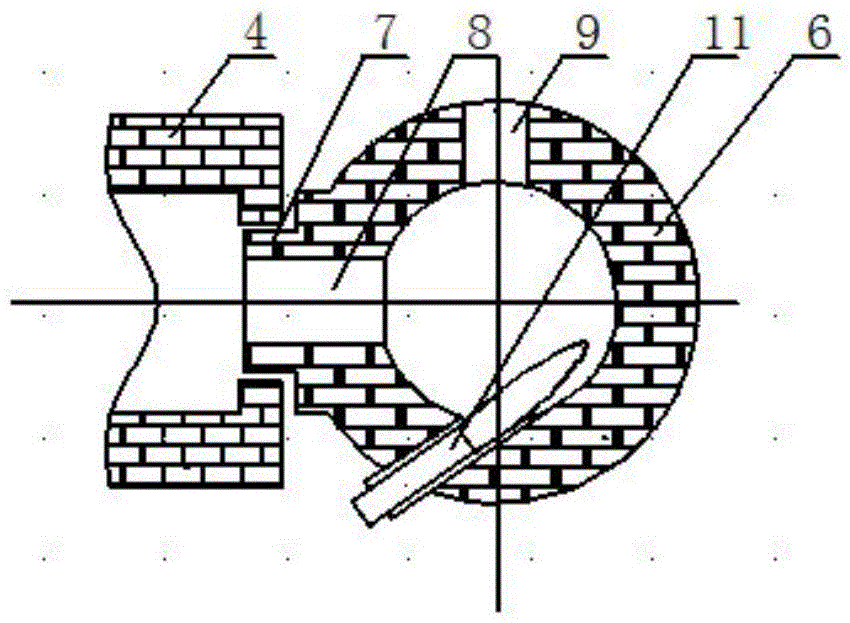

[0034] A crude copper fire refining furnace, which adopts a "shaft furnace-tiltable converter" structure, and is composed of a shaft furnace 6 and a converter 4. The lower part of the shaft furnace is radially connected with a connecting boss 7, and the connecting boss is coaxial The converter is connected to the converter, and the converter rotates coaxially on the connecting boss of the shaft furnace, and the flow port 8 formed by the connecting boss of the shaft furnace is connected to the hearth of the converter.

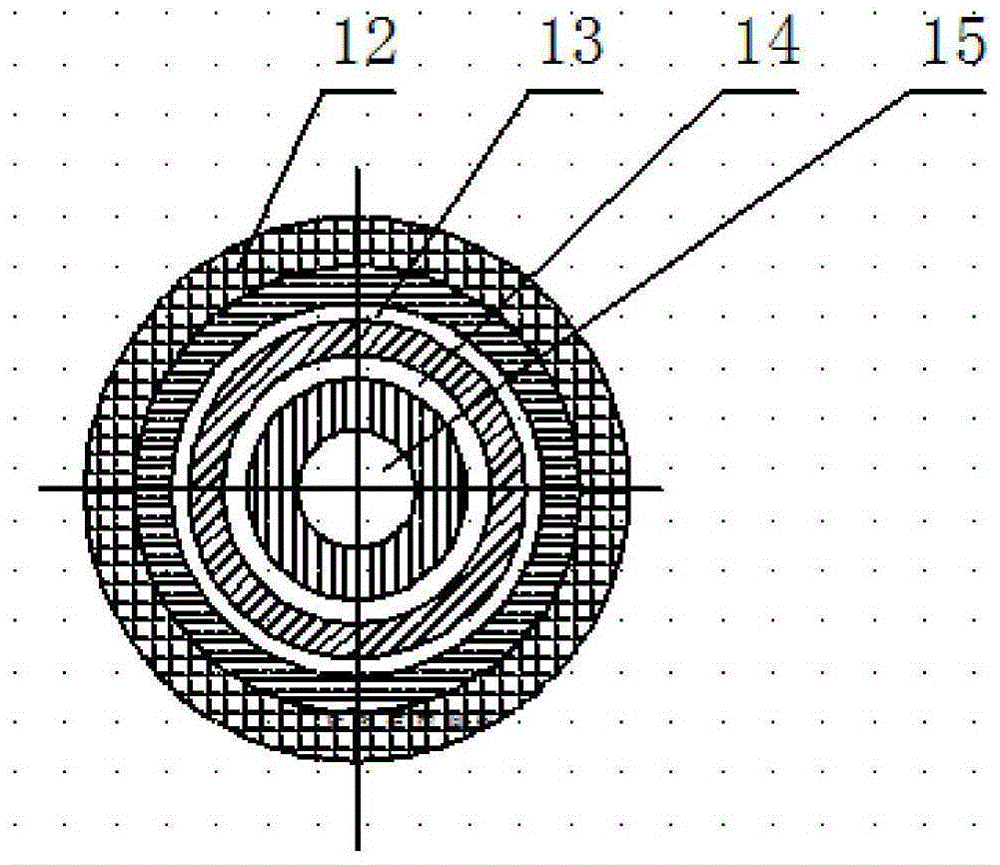

[0035] The converter is in the shape of a horizontal cylinder, with a steel shell and high-temperature refractory materials inside; on the outer cylindrical surface of the converter, ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com