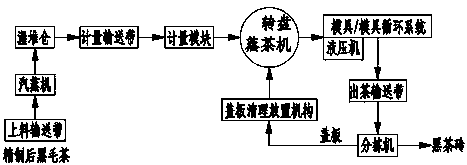

Continuous dark green tea pressing production line

A production line and technology for dark tea, applied in the field of fully automatic dark tea processing and production equipment, can solve the problems of hygienic and safety to be improved, inability to achieve continuity and automation, complex mechanical structure and control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail through examples below in conjunction with the accompanying drawings, but the scope of the present invention is not limited in any way.

[0012] Such as figure 2 , the refined and screened black hair tea is sent to the spiral steamer (2) through the feeding oblique feeding (1), the steaming time is generally 50 seconds, and the steam temperature is 98-102°, steaming is to remove the hair tea by high temperature Harmful molds brought or bred by long-term storage encourage beneficial bacteria to eliminate the interference of miscellaneous bacteria under suitable conditions; after steaming, the tea leaves fall into the pile of piles for accumulation, and the complex physical and chemical changes are promoted by the combined effect of heat and humidity, eliminating green mold. Miscellaneous smell; the accumulation time is generally 8-14 hours, and the accumulated leaf temperature is generally 75°C-88°C. In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com