Temperature-sensitive-type intelligent nano particles used in drilling fluid and preparation method thereof

A temperature-sensitive, nano-particle technology, applied in the field of oil drilling, can solve problems such as restricting the process of shale gas exploration and development, achieve good monodispersity, avoid foaming problems, and enhance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

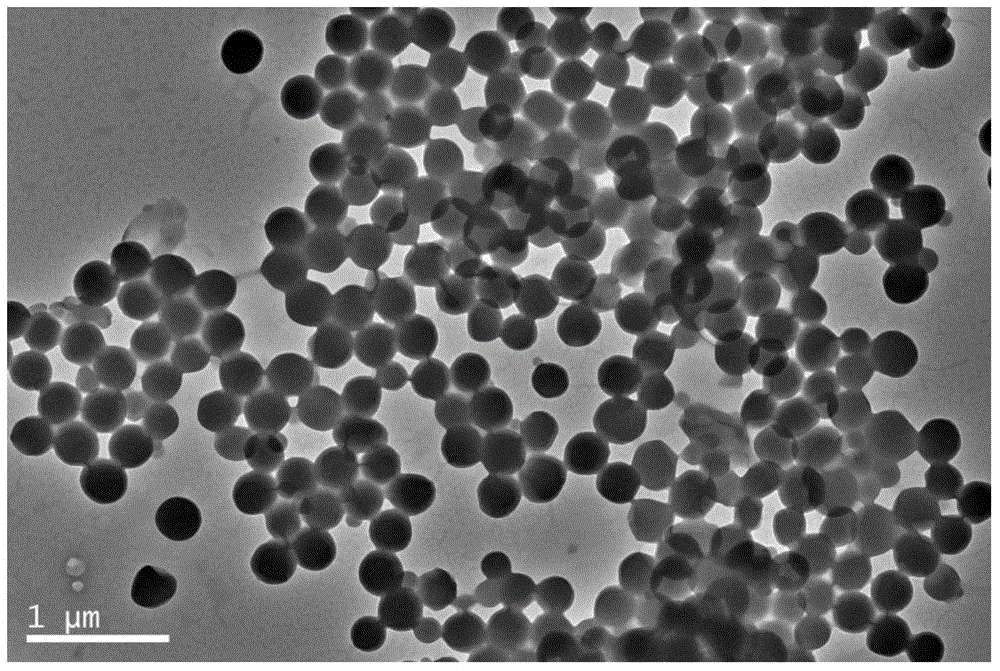

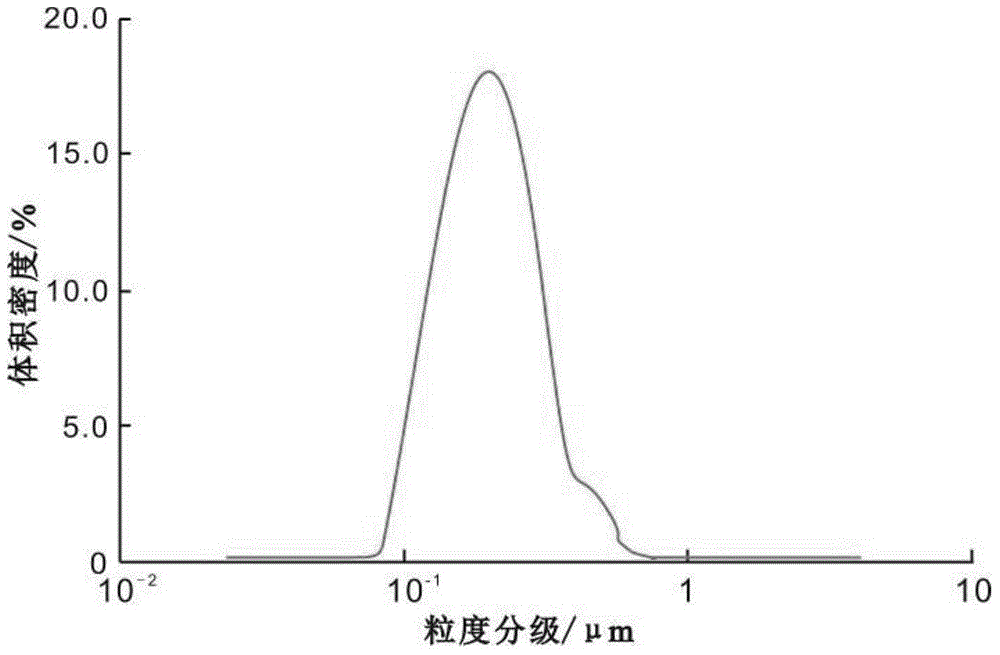

Image

Examples

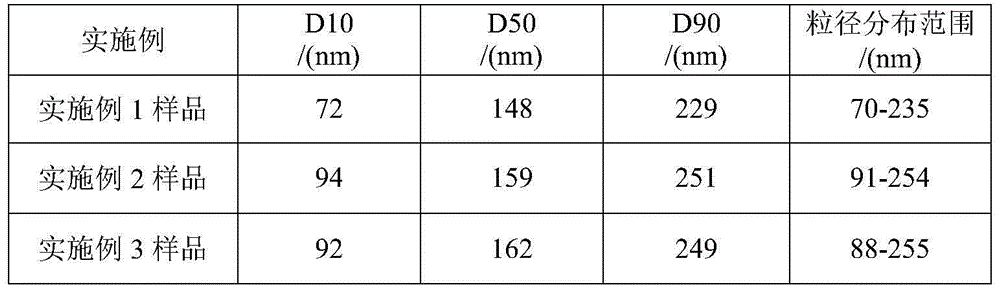

Embodiment 1

[0041] (1) Nano SiO 2 Surface modification of powder

[0042] nano-SiO 2 The powder was dried in a vacuum oven at 120°C for 24 hours, and 20g of SiO 2 Disperse in 50mL of absolute ethanol, ultrasonically disperse at 600W power for 1h, take another 0.96g of silane coupling agent KH570 and dissolve in absolute ethanol, mix the two, continue ultrasonic treatment for 1-2h, then transfer to a four-necked flask, N 2 Under the conditions of atmosphere, uniform stirring and ultrasonic vibration at 85°C, react for 2-4h. After the reaction, the product is centrifuged, washed with absolute ethanol several times, and dried in a vacuum oven at 60°C for later use.

[0043] (2) Preparation of temperature-sensitive smart nanoparticles

[0044] Add 200mL of distilled water into the reaction kettle equipped with a stirrer, thermometer and heating device, add acetone 100mL, surface modified nano-SiO 2 20g, 12.3g of N-isopropylacrylamide, 9.6g of acrylic acid, stirred at 1500r / min high speed ...

Embodiment 2

[0046] (1) Nano SiO 2 Surface modification of powder

[0047] nano-SiO 2 Dry the powder in a vacuum oven at 120°C for 24 hours, weigh 15g of SiO 2 Disperse in 50mL of absolute ethanol, ultrasonically disperse at 900W power for 1h, take another 1.32g of silane coupling agent KH550 and dissolve in absolute ethanol, mix the two, continue ultrasonic treatment for 2-3h, then transfer to a four-necked flask, N 2 Under the conditions of atmosphere, uniform stirring and ultrasonic vibration at 85°C, react for 2-4h. After the reaction, the product is centrifuged, washed with absolute ethanol several times, and dried in a vacuum oven at 60°C for later use.

[0048] (2) Preparation of temperature-sensitive smart nanoparticles

[0049] Add 300mL of distilled water to the reaction kettle equipped with stirrer, thermometer and heating device, add acetone 150mL, surface modified nano-SiO 2 25g, N,N-dimethylacrylamide 16.7g, methacrylic acid 11.2g, 1000r / min high-speed stirring to form a ...

Embodiment 3

[0051] (1) Nano SiO 2 Surface modification of powder

[0052] nano-SiO 2 The powder was dried in a vacuum oven at 120°C for 24 hours, and 25g of SiO 2 Disperse in 80mL of absolute ethanol, ultrasonically disperse at 1000W for 1.2h, take another 2.1g of silane coupling agent A-151 and dissolve in absolute ethanol, mix the two, continue ultrasonic treatment for 2-3.5h, then transfer to four flask, N 2 Under the conditions of atmosphere, uniform stirring and ultrasonic oscillation at 75°C, react for 3-4h. After the reaction, the product is centrifuged, washed with absolute ethanol several times, and dried in a vacuum oven at 60°C for later use.

[0053] (2) Preparation of temperature-sensitive smart nanoparticles

[0054] Add 250mL of distilled water to a reaction kettle equipped with a stirrer, a thermometer and a heating device, and add 130mL of isopropanol, surface-modified nano-SiO 2 26.1g, N-isopropylacrylamide 12.3g, methyl acrylate, styrene 9.6g, 2000r / min high-speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com