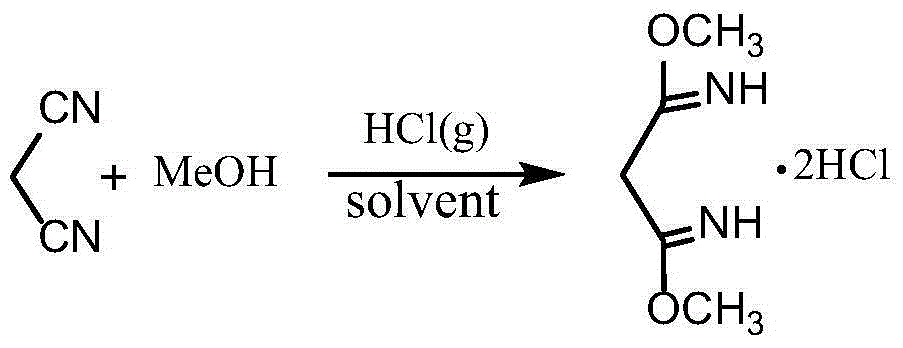

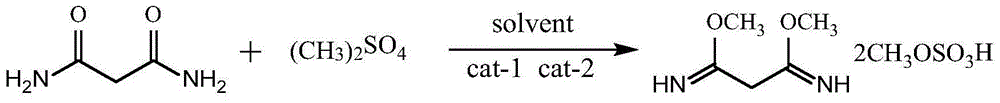

Novel preparation method of dimethoxy propyl diimine dimethyl bisulfate

A technology of dimethoxypropanediimide dimethyl hydrogen sulfate and a new method, applied in the field of pesticides, can solve the problems of inability to track, environmental pollution, and high cost, and achieve significant social and economic benefits, environmental friendliness, and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Pour 240L of solvent toluene into a 500L glass-lined kettle with a metering pump, start stirring, add 20kg of 98% malonamide, add 0.2kg of the first catalyst PEG400 and 0.1kg of the second catalyst boron trifluoride, and pass through the elevated tank at room temperature. Add 54kg of dimethyl sulfate dropwise into the kettle for 15 minutes, turn on the steam to slowly raise the temperature, keep the temperature at 70°C for 15 hours, the gas phase tracking detects that the content of malonamide is less than 1%, cool down to -5°C, and use a 500L fully enclosed The multi-functional stainless steel double cone is used for solid-liquid separation, and dried at a vacuum degree of -0.095Mpa and a temperature of 60°C to obtain 66kg of white powdery solid, which is dimethoxypropanediimide dimethyl hydrogensulfate, and the purity of HPLC is 96.04 %, the productive rate is 93.22% based on malonamide.

Embodiment 2

[0038]Pump 240L of solvent toluene into a 500L glass-lined kettle, start stirring, add 20kg of 98% malonamide, add 0.3kg of the first catalyst tetrabutylammonium bisulfate and 0.2kg of the second catalyst boron trifluoride, and Add 54kg of dimethyl sulfate dropwise to the kettle through the head tank, drop the time for 15 minutes, turn on the steam to slowly raise the temperature, keep the temperature at 80°C for 12 hours, and detect that the malonamide content is less than 1% by gas phase tracking, cool down to -0°C, and use The fully enclosed multifunctional stainless steel double cone is used for solid-liquid separation, and dried at a vacuum degree of -0.095Mpa and a temperature of 80°C to obtain 66kg of white powdery solid, which is dimethoxypropanediimide dimethyl hydrogensulfate, detected by HPLC The purity is 96.55%, and the yield is 93.71% based on malonamide.

Embodiment 3

[0040] Use a pump to pump 260L of solid-liquid separation mother liquor into a 500L glass-lined kettle, start stirring, add 20kg of 98% malonamide, add 0.2kg of the first catalyst PEG400 and 0.1kg of the second catalyst boron trifluoride, and pass through the high-level Add 54kg of dimethyl sulfate dropwise into the tank for 15 minutes, turn on the steam to slowly raise the temperature, keep the temperature at 90°C for 12 hours, and detect that the malonamide content is less than 1% by gas phase tracking, cool down to -5°C, and use a fully enclosed A multifunctional stainless steel double cone is used for solid-liquid separation, and dried at a vacuum degree of -0.095Mpa and a temperature of 90°C to obtain 70kg of white powdery solid, which is dimethoxypropylenediimide dimethyl hydrogensulfate. The purity of HPLC is 95.44%, and the yield is 98.25% based on malonamide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com