Preparation method of anti-water-type low-temperature NH3-SCR catalyst, catalyst prepared therewith and application of the catalyst

A technology of catalysts and composite oxides, applied in the direction of physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of catalyst water resistance and achieve good NH3- The effects of SCR water resistance, simple and quick preparation method, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1. Mn 0.2 Ti 0.8 o 2 sample preparation

[0025] Dissolve 0.98g of manganese acetate tetrahydrate in 28mL of absolute ethanol, add 1mL of water and 1mL of glacial acetic acid under magnetic stirring, and stir evenly. 5 mL of tetrabutyl titanate was added to the above solution, and stirred for 30 min. The reaction solution was transferred to a stainless steel hydrothermal reaction kettle with a polytetrafluoroethylene liner of 50 mL, and placed in an oven at 180° C. for 24 h. Cool to room temperature, centrifuge, wash with water and ethanol three times, and dry overnight at 60°C. The obtained sample was calcined in a muffle furnace for 4 hours in an air atmosphere (calcination temperature 550 ° C, heating time 150 min), to obtain Mn 2 Ti 8 sample.

Embodiment 2

[0026] Example 2. Mn 0.2 Ti 0.8-x Si x o 2 Catalyst preparation

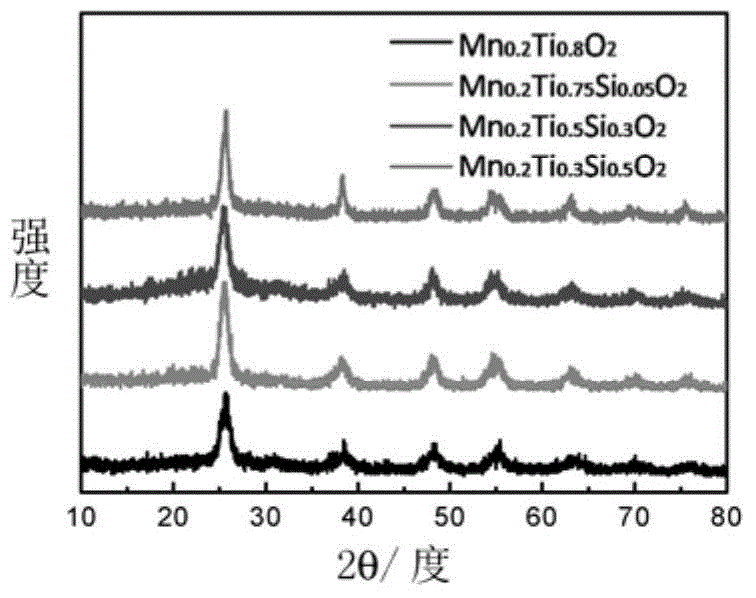

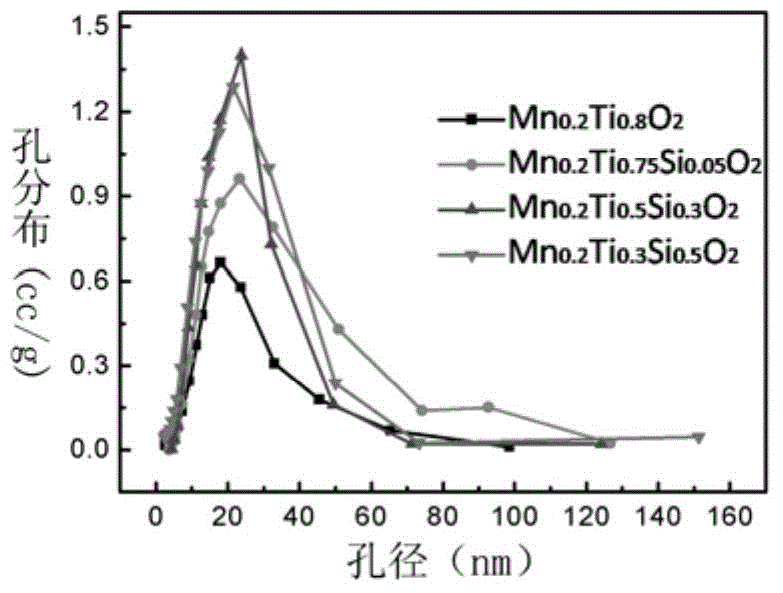

[0027] With the Mn prepared in embodiment 1 0.2 Ti 0.8 o 2 Disperse 1 g of the sample in 100 mL of n-hexane, add x mL of hexamethyldisiloxane (0.50.2 Ti 0.8-x Si x o 2 sample. The XRD results showed that the prepared catalysts were all in the anatase crystal form (such as figure 1 ). The BET results show that the pore volume of Si-treated samples increases (as shown in Table 1), and the pore diameter moves toward the large pores (as shown in Table 1). figure 2 ).

[0028] Table 1

[0029]

Embodiment 3

[0030] Example 3. NH of the catalyst 3 -SCR performance evaluation

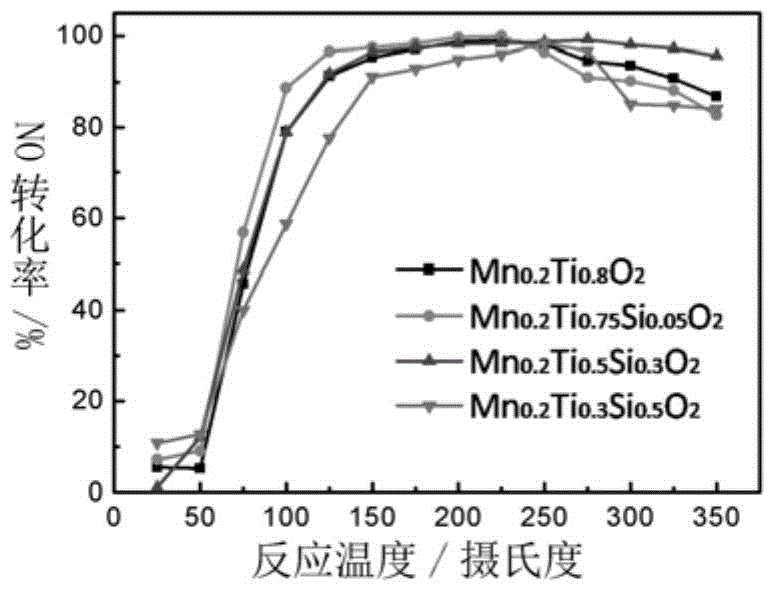

[0031] The catalyst prepared in embodiment 1,2 is applied to NH 3 -SCR response, Mn 0.2 Ti 0.8-x Si x o 2 and Mn 0.2 Ti 0.8 o 2 The catalysts all showed good low-temperature catalytic activity, indicating that the introduction of the inert species Si did not reduce the activity of the catalyst, such as image 3 shown. The reaction is carried out on a micro-reaction catalytic device, and the reaction gas composition is 500ppmNH 3 , 500ppmNO, 5%O 2 , the residual gas is N 2 , the airspeed is 100,000h -1 , the amount of catalyst used is 0.1g, the temperature of the catalytic reaction is 25-350° C., and the NO conversion rate of the reaction is detected by an infrared method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com