Preparation method of NiTi alloy tooth arch wire for orthodontics

A dental arch wire and alloy wire technology, which is applied in the field of preparation of NiTi alloy dental arch wire for orthodontics, can solve the problems of low bonding strength of film base, uneven pigment dispersion, and low corrosion resistance, and achieve mechanical properties and biological Excellent compatibility, high bonding strength of film base, and reduced corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

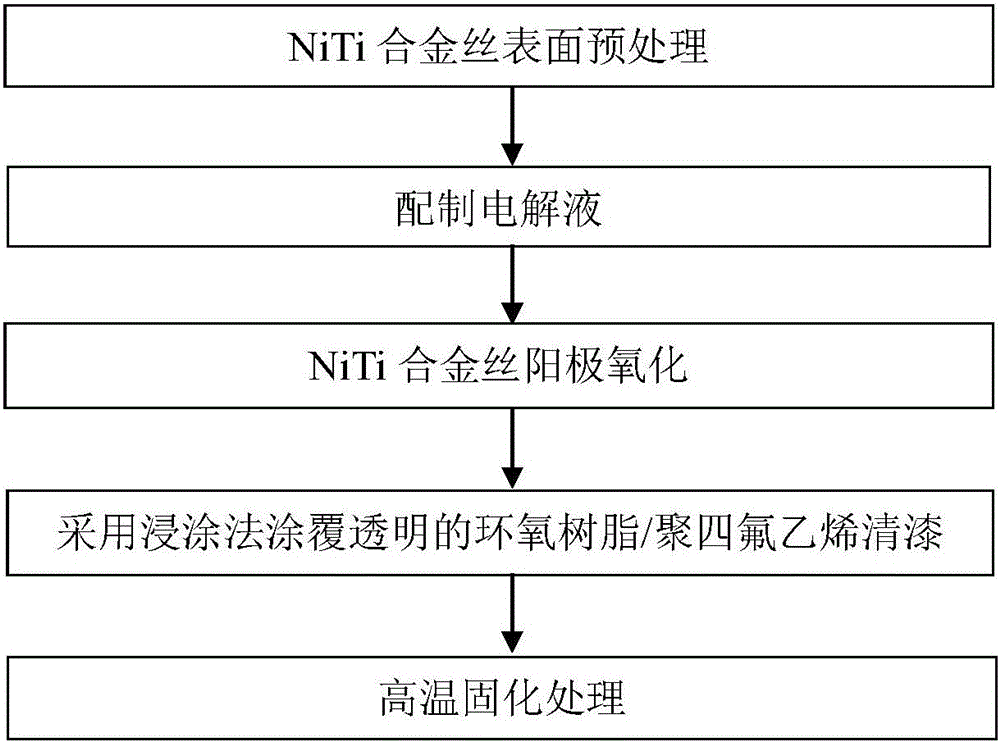

[0022] figure 1 The implementation process of the method for preparing the NiTi alloy arch wire for orthodontics according to the embodiment of the present invention is shown. The preparation method of the NiTi alloy arch wire for orthodontics provided by the embodiment of the present invention, the specific method steps are as follows:

[0023] 1) Surface pretreatment of NiTi alloy wire: remove the scratches on the surface of the alloy wire, then put it into a container filled with alcohol, perform ultrasonic cleaning at room temperature, and finally put it in an alkaline solution to remove the surface contamination layer;

[0024] 2) Preparation of electrolyte: Mix 250g / L sodium gluconate, 100mL / L phosphoric acid and 45mL / L hydrogen peroxide at a volume ratio of 1:1:1, stir until fully dissolved, prepare electrolyte, and set aside;

[0025] 3), NiTi alloy wire anodizing: put the NiTi alloy wire pretreated in step 1) into the electrolyte solution prepared in step 2), and car...

Embodiment 1

[0040] The preparation method of the NiTi alloy arch wire for orthodontics in this embodiment is carried out according to the following steps:

[0041] 1) Surface pretreatment of NiTi alloy wire: use 400#, 600#, 800#, and 1200# sandpaper to polish the wire until there is no obvious scratch on the surface, then put it into a beaker filled with alcohol, and put it in a beaker at room temperature Ultrasonic cleaning for 20 to 30 minutes, and finally put into 5mol / L NaOH solution to remove the surface contamination layer. In this embodiment, the purity of the alcohol used is ≥99%;

[0042] 2), preparation electrolyte: 250g / L sodium gluconate (C 6 h 11 NaO 7 ), 100mL / L phosphoric acid (H 3 PO 4 ) and 45mL / L hydrogen peroxide (H 2 o 2 ) according to the volume ratio of 1:1:1, mixed and stirred until fully dissolved, configured as an electrolyte solution, and set aside;

[0043] 3), NiTi alloy wire anodizing: the NiTi alloy wire pretreated in step 1) is wound with a copper wir...

Embodiment 2

[0047] The preparation method of the NiTi alloy dental arch wire for orthodontics in this embodiment is the same as that in Embodiment 1, except that when the NiTi alloy wire is anodized, the DC power supply voltage is 40V, and the oxidation time is 40 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com