Low-cost high-tenacity super wear-resistant steel and manufacturing method thereof

A high-toughness, low-cost technology, applied in the field of low-alloy wear-resistant materials, can solve the problems of low elongation and impact toughness of wear-resistant steel, insignificant surface hardening effect, and high Ni content, so as to improve hardenability, Improves wear resistance and reduces production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

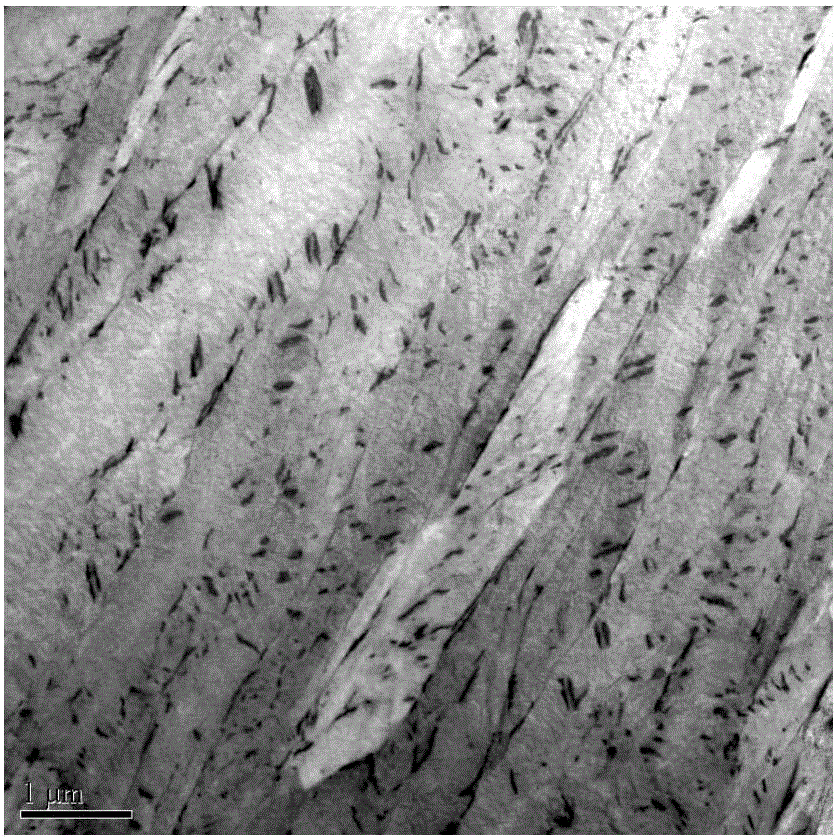

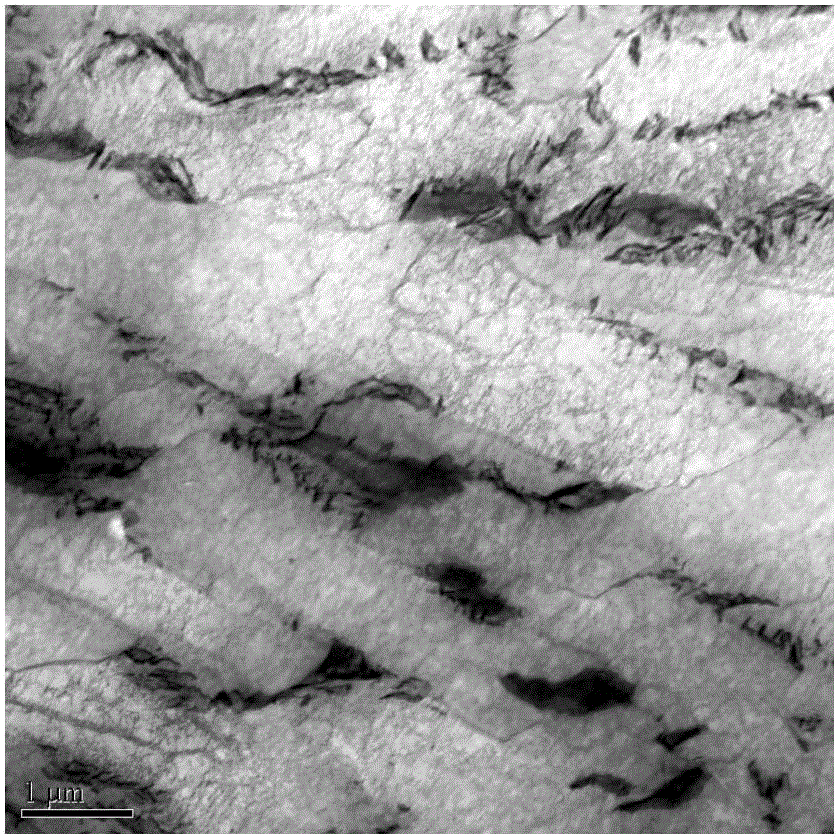

Image

Examples

Embodiment 1

[0037] The smelting of wear-resistant steel in this embodiment uses pure iron, scrap steel and ferroalloy, and is smelted in a vacuum heating furnace. After casting and forming, after high-pressure dephosphorization, the above process is carried out for hot rolling, and then heat treatment.

[0038] The low-alloy wear-resistant steel of this embodiment contains the following chemical elements: carbon 0.41%, Si: 1.60%, Mn: 0.22%, Ti: 0.20%, B: 0.001%.

[0039] In this example, the steel plate after rolling is heated from room temperature to 910°C at a heating rate of 12°C / S with the furnace, and then cooled to 100°C in a salt bath after being kept for 2.5H minutes, and then heated at a heating rate of 25°C / s from 100°C to 910°C. ℃ heated to 300 ℃ for 98 seconds, then kept at 160 ℃ for 6H minutes, and finally out of the oven and air-cooled to room temperature.

[0040] The mechanical performance test shows that the tensile strength of the wear-resistant steel is 1400MPa, the yi...

Embodiment 2

[0042] The low-alloy wear-resistant steel of this embodiment contains the following chemical elements: carbon 0.98%, Si: 3.3%, Mn: 0.25%, Ti: 0.22%, B: 0.003%.

[0043] After rolling, the steel plate is heated from room temperature to 850°C at a heating rate of 8°C / S with the furnace, cooled to 120°C in a salt bath after holding for 2.8H minutes, and then heated from 120°C to 281°C at a heating rate of 15°C / s Keep warm for 80 seconds, then keep warm at 250°C for 7H minutes, and finally take it out of the oven and air cool to room temperature.

[0044] The mechanical performance test shows that the tensile strength of the wear-resistant steel is 1480MPa, the yield strength is 1080MPa, the hardness value is 432HV, the elongation is 14.7%, and the impact toughness is 48J / cm2.

Embodiment 3

[0046] The low-alloy wear-resistant steel of this embodiment contains the following chemical elements: 0.55% carbon, 2.5% Si, 0.70% Mn, 0.30% Ti, and 0.005% B.

[0047] After rolling, the steel plate is heated from room temperature to 880°C at a heating rate of 20°C / S with the furnace, cooled to 249°C in a salt bath after holding for 3H minutes, and then heated from 249°C to 300°C at a heating rate of 20°C / s. 50 seconds, then keep warm at 180°C for 7.8H minutes, and finally take it out of the oven and air cool to room temperature.

[0048] The mechanical performance test shows that the tensile strength of the wear-resistant steel is 1502MPa, the yield strength is 1178MPa, the hardness value is 440HV, the elongation is 16.7%, and the impact toughness is 61J / cm2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com