Wet process dust collecting and leaching electrodeposition integrated technology for zinc-contained solid waste disposal

A wet dust collection and leaching technology, which is applied in the direction of photography technology, photography auxiliary technology, and improvement of process efficiency, can solve the problems of frequent replacement cycles, environmental pollution, and high operating costs, so as to save investment in infrastructure equipment and land occupation, The effect of reducing the process and saving capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

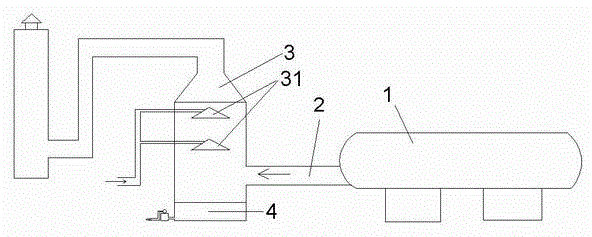

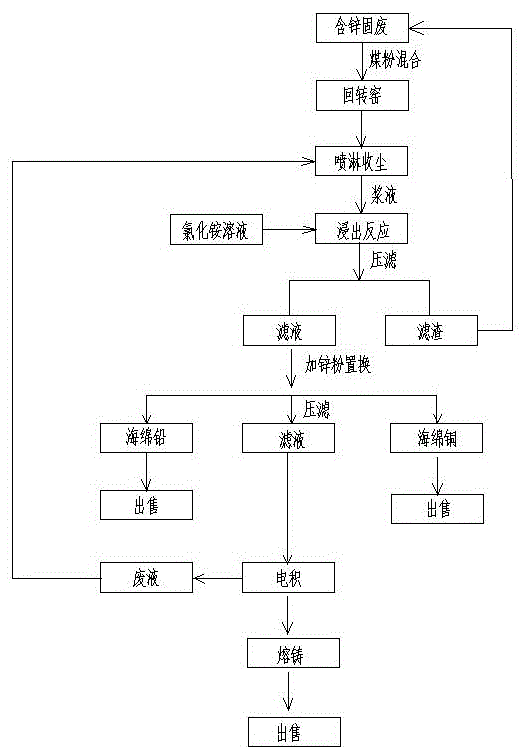

Method used

Image

Examples

Embodiment 4

[0066] Raw material A, Zn45.2%, Fe4.2%, Pb5.8%, Cl8.5%, F0.6%; add 50gA to 1000ml solution containing ammonium chloride 300g / L, temperature is 50℃, reaction 1 Hours, Zn21.5g / L, Pb2.84g / L, zinc leaching rate 95.13%, lead leaching rate 97.93%; Purification: Zinc powder is added according to 0.4 times of the lead content in the leaching solution, and the purification time is 1.5 hours. The temperature is 40°C, and the lead content (dry basis) of the filter press purification residue is 85%. After purification, 2g / L zinc powder is added to the deep purification, and the impurity content (mg / L) of the filtrate is: Pb0.1, Cu0.05, Cd0 .05 ; This solution was subjected to electrolysis.

[0067] Electrolysis uses graphite as the anode, aluminum plate as the cathode, the distance between the same electrodes is 70mm, and the current density is 400A / m 2 , the electrolysis temperature is 50°C, the cell voltage is 2.72 volts, the pH value of the electrolysis is controlled by adding 25% amm...

Embodiment 5

[0070] Raw material B, composition (%): Zn48, Cu4.5, Pb2.6, 100g of B was added to 1000ml of ammonium chloride 250g / L solution, the leaching temperature was 65°C, and the leaching time was 1 hour. The composition of the filtrate after leaching (g / l): Zn45.2, Pb2.45, Cu4.3, the leaching rate of zinc is 94.17%, the leaching rate of lead is 94.23%, and the leaching rate of copper is 95.56%; add copper to the leaching solution content of 1 times zinc powder, the purification time is 0.5 hours, the purification temperature is 50 ℃, the sponge copper content (dry basis) is 75%, and then 0.4 times the lead content of zinc powder is added to obtain the lead content of the purified slag (dry basis) It is 80%, and the filtrate is electrolyzed after deep purification.

[0071] Electrolysis uses graphite as anode, aluminum plate as cathode, current density 500A / m 2 , the electrolysis temperature is 65°C, the cell voltage is 2.8 volts, 25% ammonia water is added to control the pH at 4.0-...

Embodiment 6

[0074] Raw material C, composition (%): Zn38, Pb12.8, Cl 17.2; add 100g of C into 1000ml of ammonium chloride 250g / L solution, the reaction temperature is 50°C, and the leaching time is 1 hour. The composition of the filtrate after leaching (g / l): Zn36.5, Pb12.3, the leaching rate of zinc is 96.05%, and the leaching rate of lead is 96.09%; add zinc powder 0.4 times the lead content to the leaching solution, and the purification time is 1.5 hour, the purification temperature is 50°C, and the lead (dry basis) content of the purified slag is 90%, and then 2g / L zinc powder is added for deep purification and then electrolyzed.

[0075] Electrolysis uses graphite as anode, aluminum plate as cathode, current density 450A / m 2 , the electrolysis temperature is 70°C, the cell voltage is 2.7 volts, 25% ammonia water is added to control the pH at 4.0-7, the waste liquid contains 12.5g / L of zinc, the current efficiency is 96%, and the DC power consumption of zinc precipitation is 2680Kwh / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com