A kind of preparation method of network tetragonal phase zirconia nanopowder

A technology of phase zirconia and nano-powders, which is applied in the field of preparation of net-shaped tetragonal-phase zirconia nano-powders, can solve the problems of long preparation reaction time, unfavorable industrial production, and increased production costs, and achieve the goal of overcoming long reaction time, Lower calcination temperature and faster synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.05mol Zr(NO 3 ) 4 ·5H 2 O and 0.0012mol Y (NO 3 ) 3 ·6H 2 O is dissolved in 1L of deionized water to form 0.05mol / L Zr(NO 3 ) 4 3%Y(NO 3 ) 3 Aqueous solution (1); then weigh 14.61g of EDTA, 17.8g of acrylamide, 3.56g of N,N'-methylenebisacrylamide and 0.05g of ammonium persulfate and dissolve in solution (1), and stir well . Then the above mixed solution was transferred to a water bath at 80°C for 2 hours, and after the gel was complete, it was taken out and cooled to room temperature. The gel product was directly dried at 90°C, and the obtained xerogel was raised to 300°C at a rate of 3°C / min in a ventilated annealing furnace, and kept for 2 hours, and the treated product was placed in an air atmosphere at Treat at 800°C for 2 hours to obtain network tetragonal zirconia nanopowder.

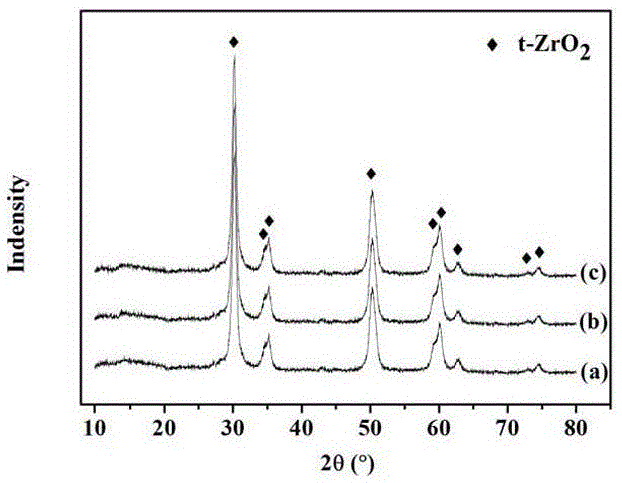

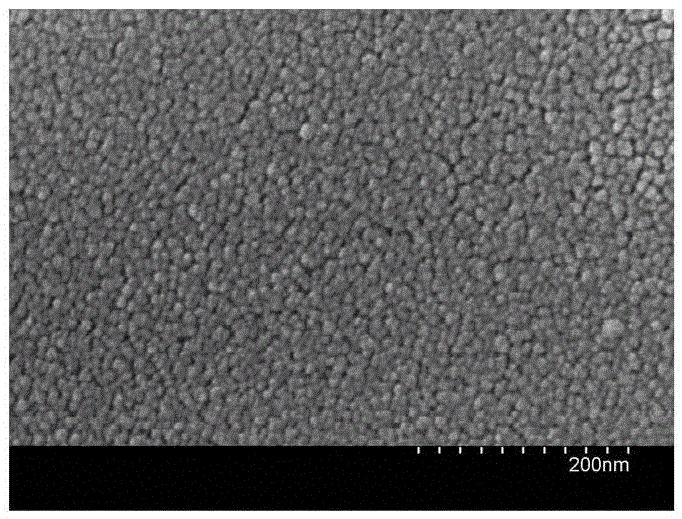

[0032] XRD analysis was carried out on the above-mentioned network tetragonal phase zirconia nanopowder, and the results showed that the product was pure tetragonal ZrO ...

Embodiment 2

[0034] Weigh 0.05molZrO(NO 3 ) 2 and 0.0025mol Y(NO 3 ) 3 ·6H 2 O is dissolved in 1L of deionized water to form 0.05mol / L ZrO(NO 3 ) 2 5% YPO 4 Aqueous solution (1); then weigh 9.61g of citric acid, 18.0g of acrylamide, 3.80g of N,N'-methylenebisacrylamide and 0.05g of ammonium persulfate and dissolve in solution (1), and Stir well to combine. Then the above mixed solution was transferred to a water bath at 80°C for 2 hours, and after the gel was complete, it was taken out and cooled to room temperature. The gel product was directly dried at 90°C, and the obtained dry gel was raised to 320°C at a rate of 3°C / min in a ventilated annealing furnace, and kept for 2 hours, and the treated product was heated in an air atmosphere at 700°C ℃ treatment for 2 hours to obtain network tetragonal phase zirconia nanopowder.

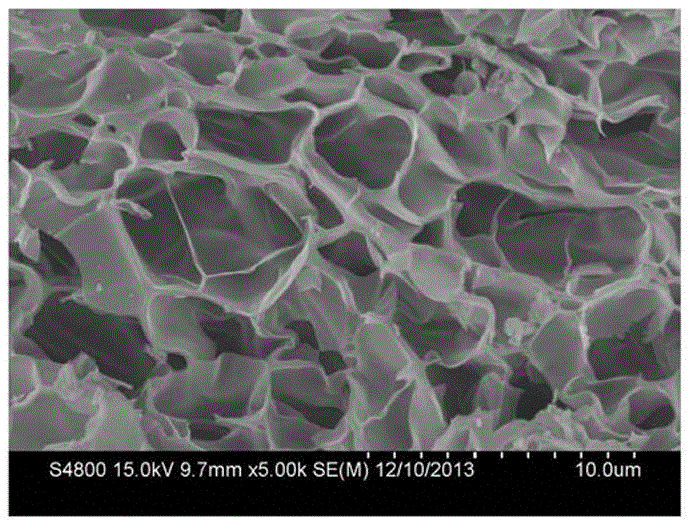

[0035] The XRD analysis of the above network tetragonal zirconia nanopowder shows that the main component of the product is pure tetragonal ZrO 2 powder (see...

Embodiment 3

[0037] Weigh 0.06molZr(CH 3 COO) 4 and 0.0021molY 2 (SO 4 ) 3 ·8H 2 O was dissolved in 1.2L of deionized water to form 0.05mol / L of Zr(CH 3 COO) 4 7%Y 2 (SO 4 ) 3 aqueous solution (1); then weigh 17.53g of EDTA, 18.2g of acrylamide, 4.00g of N,N'-methylenebisacrylamide and 0.05g of ammonium persulfate and dissolve in solution (1), and fully Stir well. Then the above mixed solution was transferred to a water bath at 80°C for 2 hours, and after the gel was complete, it was taken out and cooled to room temperature. The gel product was directly dried at 90°C, and the obtained dry gel was raised to 280°C at a rate of 3°C / min in a ventilated annealing furnace, and kept for 2 hours, and the treated product was placed in an air atmosphere at Treat at 1000°C for 2 hours to obtain network tetragonal zirconia nanopowder.

[0038] The XRD analysis of the above network tetragonal zirconia nanopowder shows that the main component of the product is pure tetragonal ZrO 2 powder (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com