Preparation method of meshy tetragonal phase zirconia nano powder

A technology of phase zirconia and nano-powder, which is applied in the field of preparation of net-shaped tetragonal-phase zirconia nano-powder, can solve the problems of long preparation reaction time, unfavorable industrial production, harsh preparation process, etc., to overcome long reaction time, Lower calcination temperature and faster synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.05mol Zr(NO 3 ) 4 ·5H 2 O and 0.0012mol Y (NO 3 ) 3 ·6H 2 O is dissolved in 1L of deionized water to form 0.05mol / L Zr(NO 3 ) 4 3%Y(NO 3 ) 3 Aqueous solution (1); then weigh 14.61g of EDTA, 17.8g of acrylamide, 3.56g of N,N'-methylenebisacrylamide and 0.05g of ammonium persulfate and dissolve in solution (1), and stir well . Then the above mixed solution was transferred to a water bath at 80°C for 2 hours, and after the gel was complete, it was taken out and cooled to room temperature. The gel product was directly dried at 90°C, and the obtained xerogel was raised to 300°C at a rate of 3°C / min in a ventilated annealing furnace, and kept for 2 hours, and the treated product was placed in an air atmosphere at Treat at 800°C for 2 hours to obtain network tetragonal zirconia nanopowder.

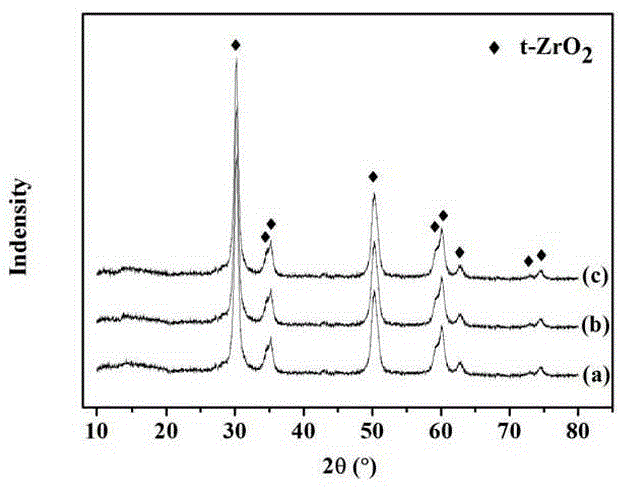

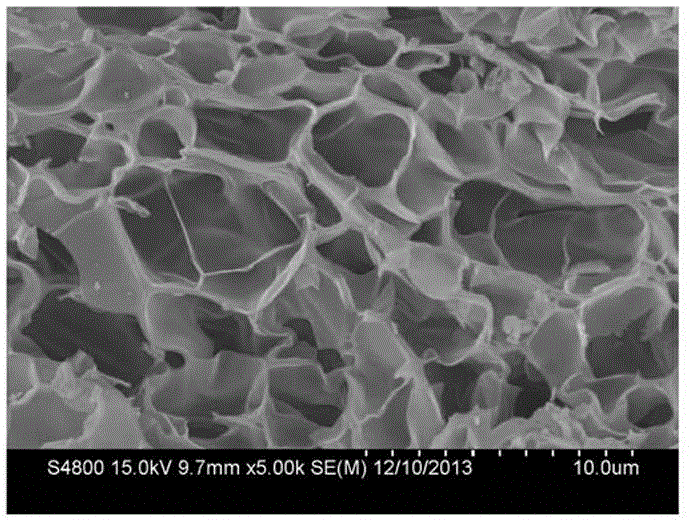

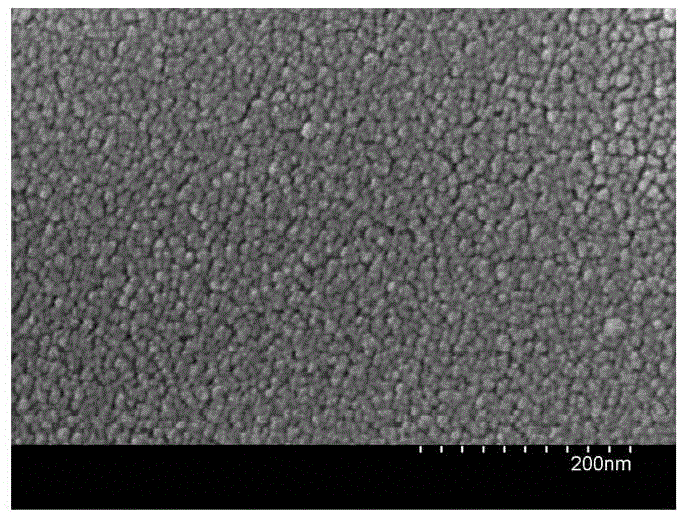

[0032] XRD analysis was carried out on the above-mentioned network tetragonal phase zirconia nanopowder, and the results showed tha...

Embodiment 2

[0034] Weigh 0.05molZrO(NO 3 ) 2 and 0.0025mol Y(NO 3 ) 3 ·6H 2 O is dissolved in 1L of deionized water to form 0.05mol / L ZrO(NO 3 ) 2 5% YPO 4 Aqueous solution (1); then weigh 9.61g of citric acid, 18.0g of acrylamide, 3.80g of N,N'-methylenebisacrylamide and 0.05g of ammonium persulfate and dissolve in solution (1), and Stir well to combine. Then the above mixed solution was transferred to a water bath at 80°C for 2 hours, and after the gel was complete, it was taken out and cooled to room temperature. The gel product was directly dried at 90°C, and the obtained dry gel was raised to 320°C at a rate of 3°C / min in a ventilated annealing furnace, and kept for 2 hours, and the treated product was heated in an air atmosphere at 700°C ℃ treatment for 2 hours to obtain network tetragonal phase zirconia nanopowder.

[0035] The XRD analysis of the above network tetragonal zirconia nanopowder shows that the main component of the product is pu...

Embodiment 3

[0037] Weigh 0.06molZr(CH 3 COO) 4 and 0.0021molY 2 (SO 4 ) 3 ·8H 2 O was dissolved in 1.2L of deionized water to form 0.05mol / L of Zr(CH 3 COO) 4 ·7% Y 2 (SO 4 ) 3 aqueous solution (1); then weigh 17.53g of EDTA, 18.2g of acrylamide, 4.00g of N,N'-methylenebisacrylamide and 0.05g of ammonium persulfate and dissolve in solution (1), and fully Stir well. Then the above mixed solution was transferred to a water bath at 80°C for 2 hours, and after the gel was complete, it was taken out and cooled to room temperature. The gel product was directly dried at 90°C, and the obtained dry gel was raised to 280°C at a rate of 3°C / min in a ventilated annealing furnace, and kept for 2 hours, and the treated product was placed in an air atmosphere at Treat at 1000°C for 2 hours to obtain network tetragonal zirconia nanopowder.

[0038] The XRD analysis of the above network tetragonal zirconia nanopowder shows that the main component of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com